Submerged cyclone shaft sluice tunnel

A technology of swirling shafts and flood tunnels, which is applied in the field of flood tunnels, can solve problems such as unstable water flow transitions, prone to hydraulic jumps in flood tunnels, and affecting the safe operation of flood tunnels, so as to achieve improved flow conditions and good exhaust conditions Effect

Inactive Publication Date: 2010-08-25

SICHUAN UNIV

View PDF3 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The unpressurized flow in the open channel with high water head and large flow is introduced into the submerged flood discharge tunnel through the shaft, in essence, the water flow transitions from the unpressurized internal flow discharge facility (shaft) to the pressurized internal flow facility (spill tunnel), so the water flow Unfavorable hydraulic phenomena such as hydraulic jumps are prone to occur in the flood discharge tunnel, which affects the safe operation of the flood discharge tunnel.

In the existing technology, through the structural improvement of the shaft (for example, designing the shaft as a double-vortex aeration type swirl shaft), setting a pressure slope at the exit of the shaft can stabilize the flow state of the water flow and improve the cavitation and cavitation damage of the spillway. However, it is still difficult to solve the safety threat to the flood tunnel caused by the hydraulic jump in the cave due to the flooding of the flood tunnel outlet.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Login to View More

Abstract

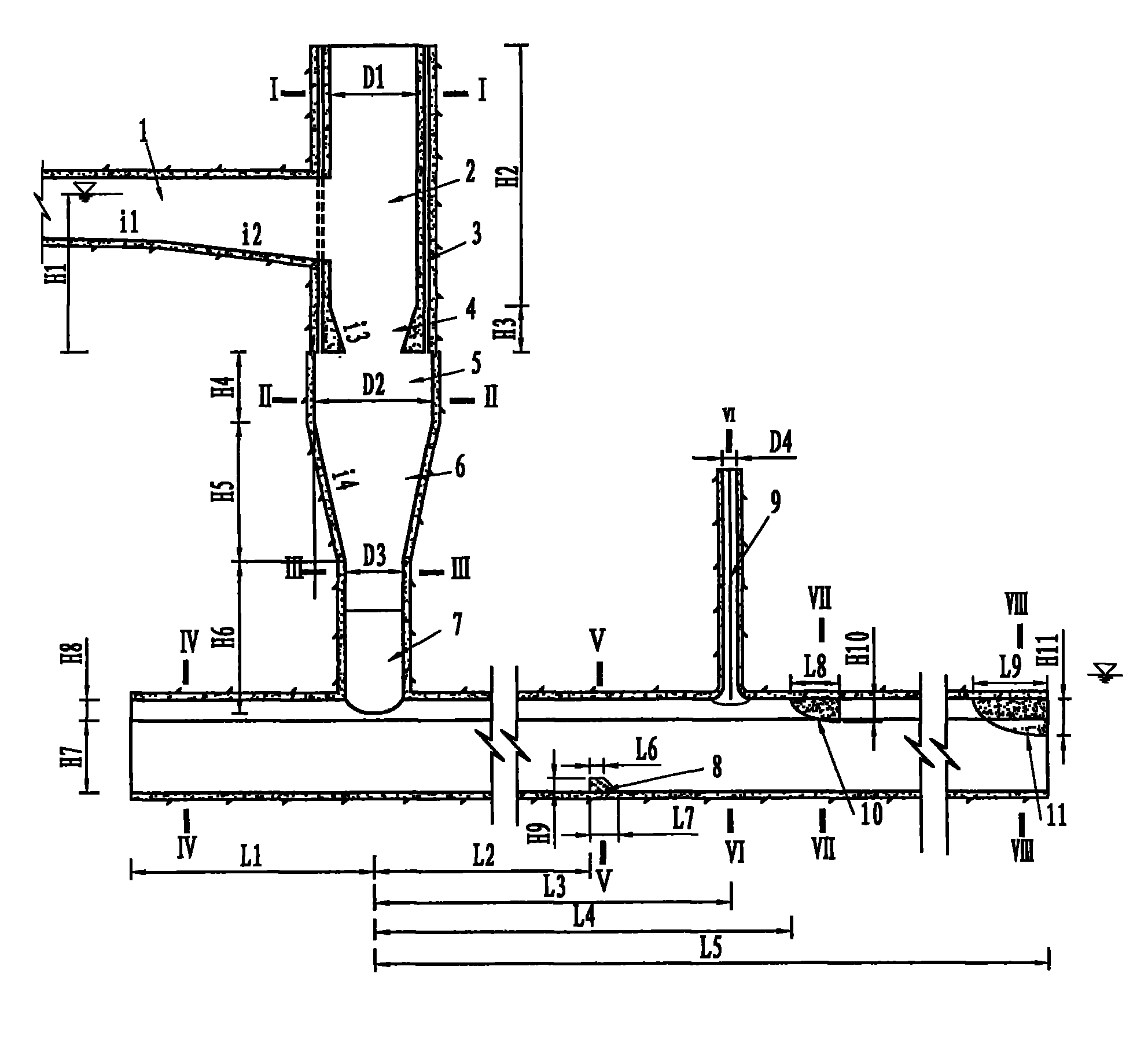

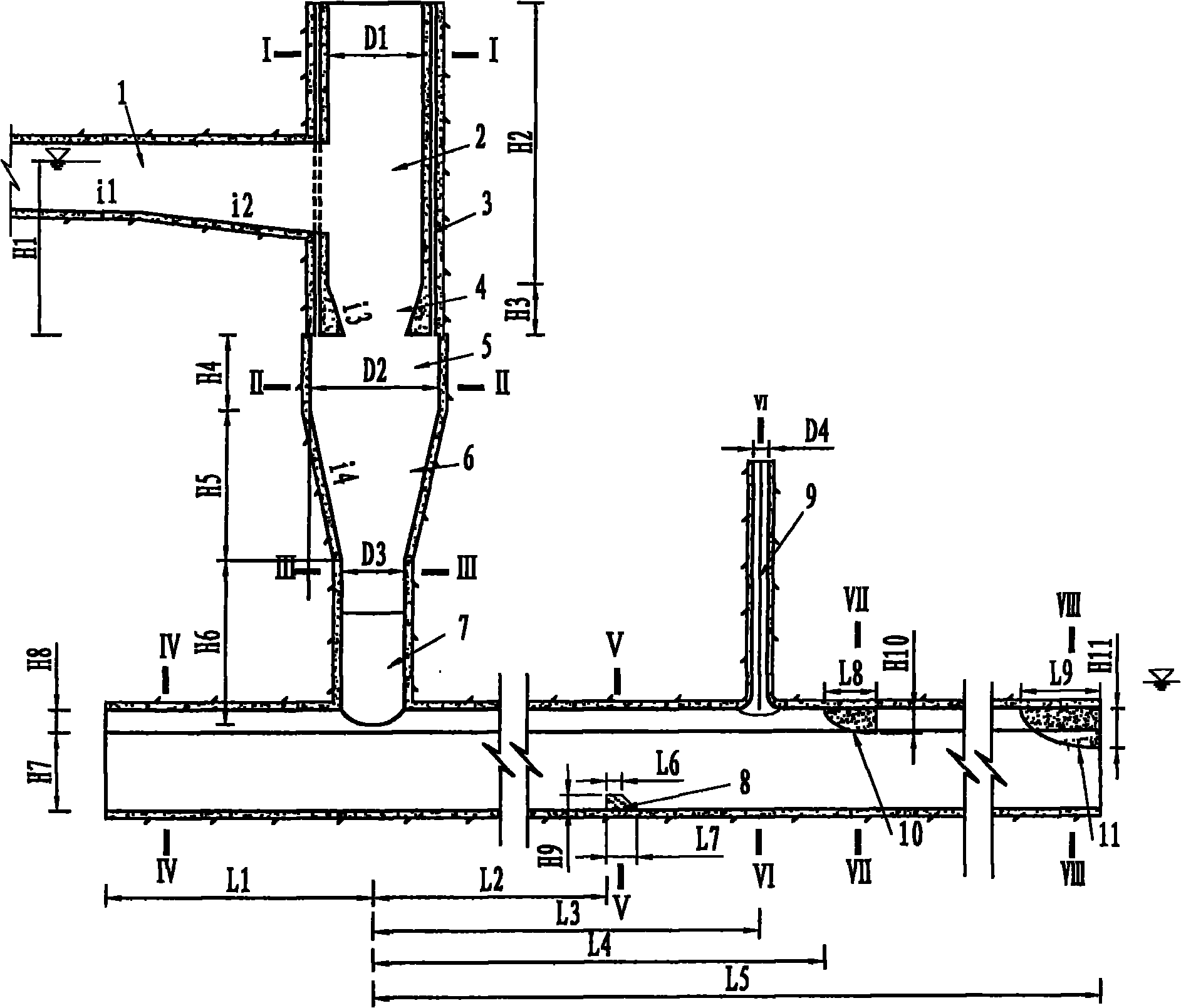

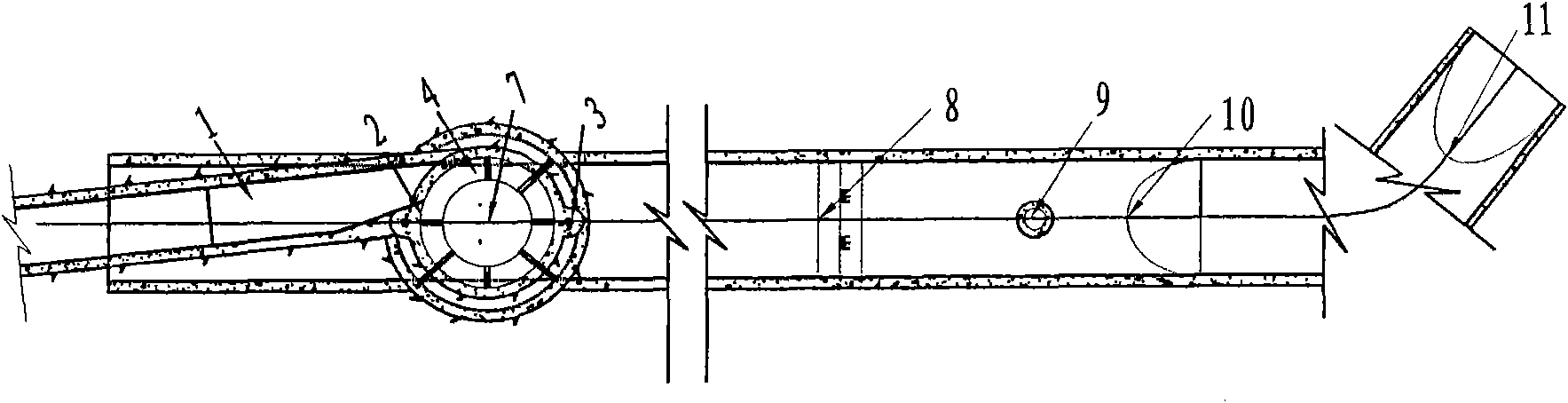

A submerged cyclone shaft sluice tunnel comprises a sluice tunnel and an aerated cyclone shaft with double volute chambers installed at the closed end of the sluice tunnel and communicated with the sluice tunnel; the sluice tunnel is internally provided with a stop part and a middle part slope; the top of the sluice tunnel is provided with an air exit hole; the aerated cyclone shaft with double volute chambers is positioned at the top of the sluice tunnel, and the central line thereof is vertical to the central line of the sluice tunnel; the stop part is installed on the bottom plate of the sluice tunnel; the distance L2 between the beginning end of the stop part and the central line of the aerated cyclone shaft with double volute chambers is equal to 5H7 to 10H7; the air exit hole is positioned in the middle of the stop part and the middle part slope; the distance L3 between the central line of the air exit hole and the central line of the aerated cyclone shaft with double volute chambers is equal to 7H7 to 15H7; the middle part slope is installed at the top of the sluice tunnel; the distance L4 between the beginning end of the middle part slope and the central line of the aerated cyclone shaft with double volute chambers is equal to 8H7 to 15H7; and the H7 in each formula is the height of the upright wall of the gate-shaped sluice tunnel.

Description

Submerged swirl shaft spillway technical field The invention belongs to the field of flood discharge tunnels of water conservancy and hydropower projects, in particular to a submerged swirl shaft flood discharge tunnel used under the conditions of high water head, large flow, and pressure flow from no pressure flow. Background technique The unpressurized flow in the open channel with high water head and large flow is introduced into the submerged flood discharge tunnel through the shaft, in essence, the water flow transitions from the unpressurized internal flow discharge facility (shaft) to the pressurized internal flow facility (spill tunnel), so the water flow Unfavorable hydraulic phenomena such as hydraulic jumps are prone to occur in the flood discharge tunnel, which affects the safe operation of the flood discharge tunnel. In the existing technology, through the structural improvement of the shaft (for example, designing the shaft as a double-vortex aeration type sw...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E02B8/06

Inventor 张建民刘善均张宗亮李云杨宜文许唯临王韦戈莉琼曲景学邓军任成瑶李忠

Owner SICHUAN UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com