Ultrasonic processing method for enhancing size accuracy of micro-electroformed apparatus

A technology of ultrasonic treatment and device size, applied in the direction of electroforming, electrolysis, etc., to achieve the effect of reducing absorption, improving dimensional accuracy, and reducing swelling

Inactive Publication Date: 2010-08-25

DALIAN UNIV OF TECH

View PDF6 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the Journal of Micromechanics and Microengineering 2004, No. 14, pages 1548-1557, a scheme of adding an isolation zone around the rubber mold pattern is proposed to reduce the influence of the swelling of the surrounding large-area PMMA colloid on the electroforming structure. This method only affects the periphery Structurally efficient, does not work for middle parts of dense, complex graphs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Login to View More

Abstract

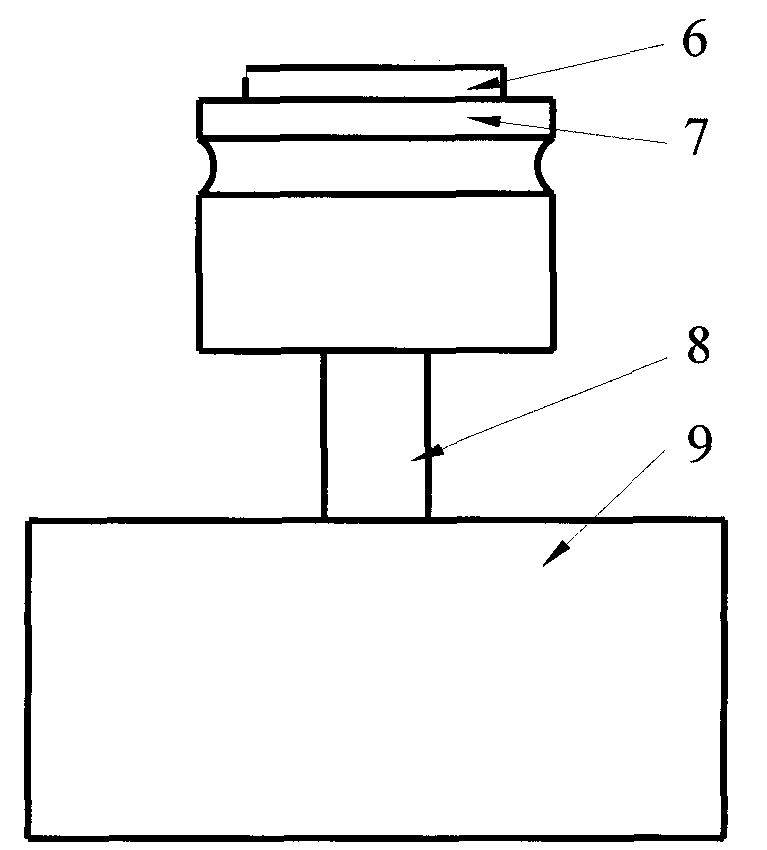

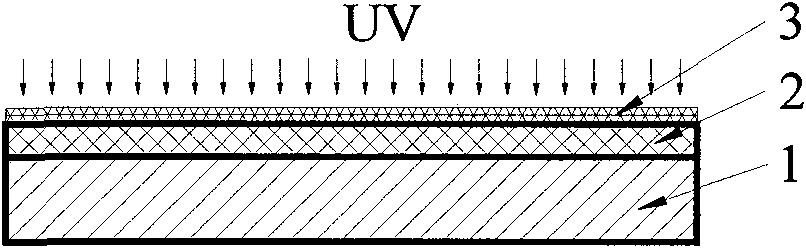

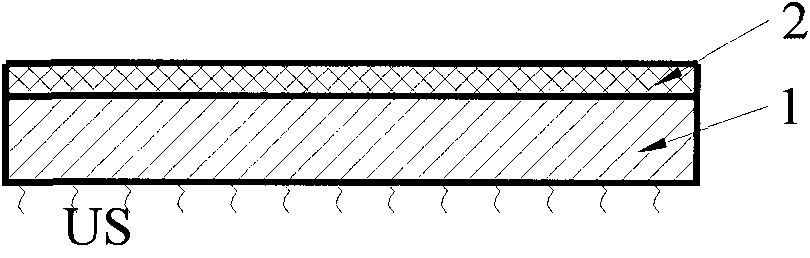

The invention relates to an ultrasonic processing method for enhancing the size accuracy of a micro-electroformed apparatus, belongs to the technical field of micro-manufacturing and particularly relates to a method for enhancing the size accuracy of the micro-electroformed apparatus. A process for manufacturing the micro-electroformed apparatus comprises the following processes: performing pretreatment on a nickel substrate, manufacturing a micro-electroformed rubber mold and performing micro-electroforming. In the process of manufacturing the micro-electroformed rubber mold, the nickel substrate coated with SU-8 rubber is fixed on an ultrasonic workbench after whirl coating, prebaking, photo-etching and after-baking are performed, is ultrasonically vibrated and developed to obtain the micro-electroformed rubber mold. The micro-electroformed rubber mold is soaked into electrotyping solution and is subjected to electro-deposition in a groove of the micro-electroformed rubber mold to form a nickel-electroformed layer. The SU-8 rubber is removed and vacuum annealing treatment is performed to eliminate residual stress. Due to the adoption of the method, the amount of the electrotyping solution absorbed by the SU-8 rubber in the electroforming process is reduced, swelling of the rubber mold is lowered and the size accuracy of the micro-electroformed apparatus is enhanced.

Description

An Ultrasonic Treatment Method for Improving Dimensional Accuracy of Micro-Electroformed Devices technical field The invention belongs to the field of micro-manufacturing technology, in particular to a method for improving the dimensional accuracy of micro-electroforming devices. Background technique The micro-electroforming technology based on the UV-LIGA process of SU-8 glue has been widely used in the manufacturing of micro-devices such as micro-sensors, micro-actuators and micro-molds. During the micro-electroforming process, the SU-8 glue will absorb the electroforming liquid, causing the volume of the plastic mold to expand and produce a swelling effect. The difference between the metal structure and the designed size after electroforming can even reach 50%. The swelling of the photoresist mold seriously affects the controllability and accuracy of the structure size of the electroformed device. In order to reduce the error caused by PMMA colloidal swelling during el...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C25D1/10

Inventor 杜立群张本状王启佳刘冲徐征刘军山

Owner DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com