Method for preparing self-cleaning polycarbonate film

A polycarbonate and self-cleaning technology, applied in the field of self-cleaning polycarbonate film preparation, can solve the problems of poor self-cleaning ability and high surface energy, and achieve excellent hydrophobic performance, low surface energy and good light transmittance Effect

Inactive Publication Date: 2010-08-25

INST OF CHEM CHINESE ACAD OF SCI

View PDF1 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although in terms of heat resistance, compared with other compounds, polyamine materials have great advantages, but their surface energy is high and their self-cleaning ability is not strong

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

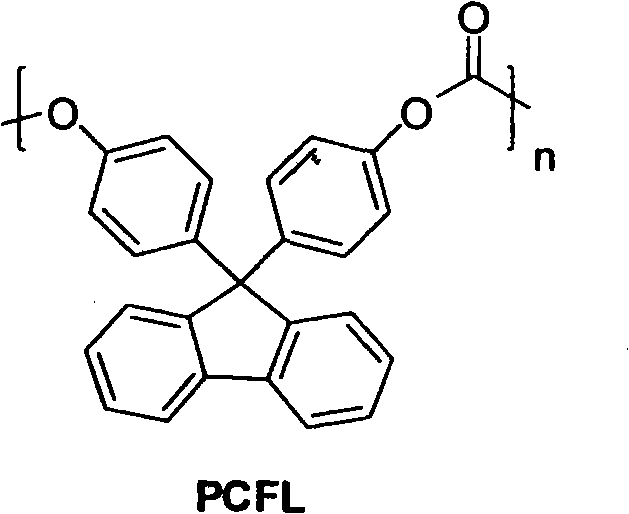

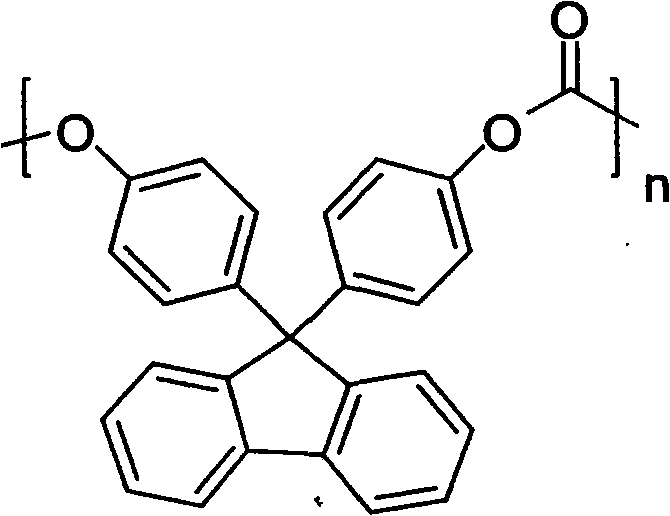

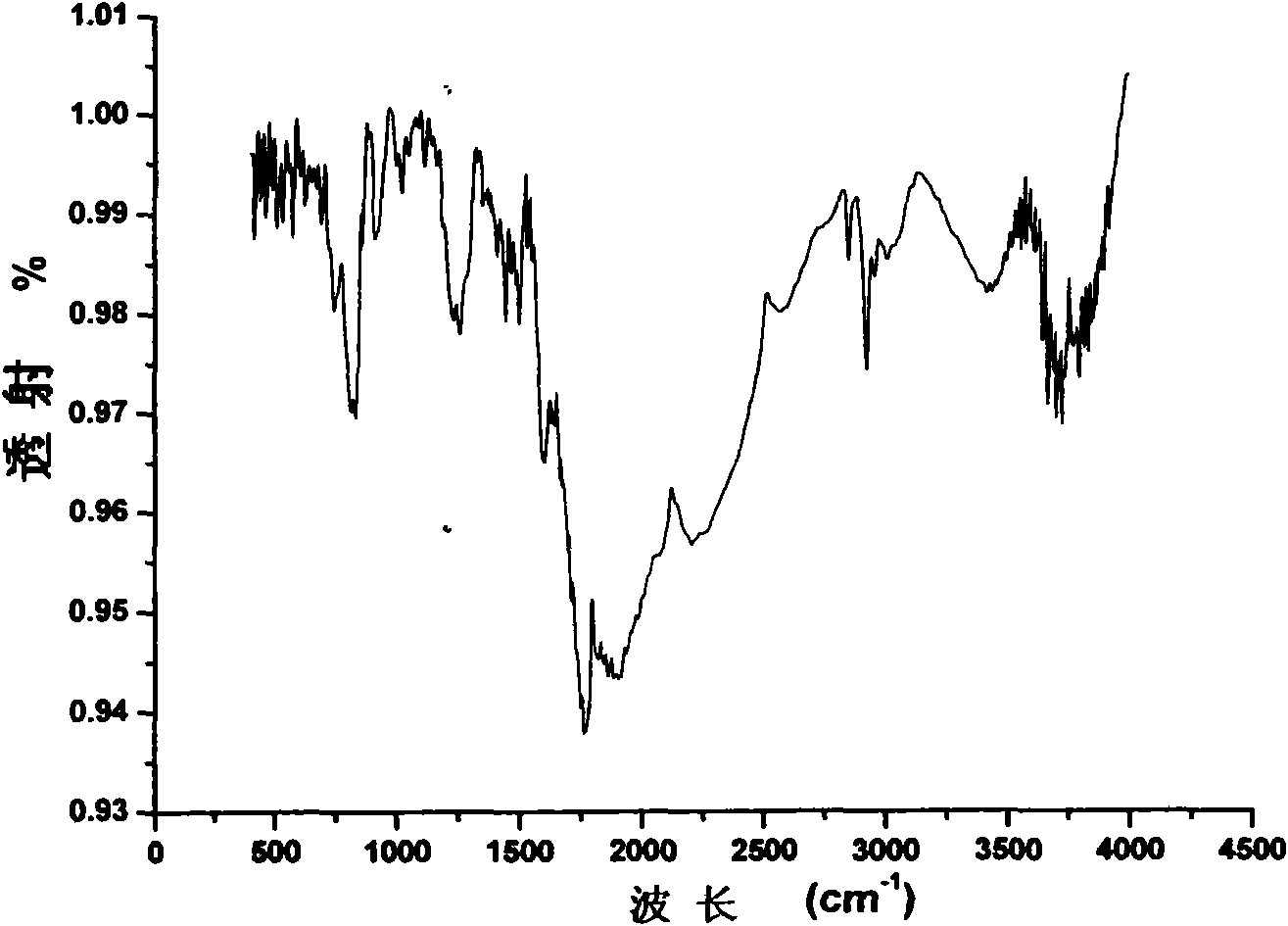

The invention belongs to the field of self-cleaning films, and in particular relates to a method for preparing a self-cleaning polycarbonate film which is fluorine-free, heat-resisting, good in light transmittance, non-toxic and self-cleaning. The method comprises the following steps of: dissolving polycarbonate materials in a dichloromethane solvent; fully stirring or ultrasonically dispersing the mixture so as to form uniform polycarbonate solution; coating the polycarbonate solution on a clean substrate so as to form a uniform film; and drying the film at room temperature after the dichloromethane solvent is completely volatilized so as to obtain the self-cleaning polycarbonate film. The self-cleaning polycarbonate film prepared by the method not only has high heat resistance (thermal decomposition temperature is 400 DEG C) and high light transmittance (the transmissivity of visible light is over 90 percent), but also has excellent hydrophobic performance (an angle for contacting water is more than 90 degrees); and the rough substrate has super-hydrophobic performance (an angle for contacting water is more than 150 degrees). The film can be applied in fields such as food and the like.

Description

technical field The invention belongs to the field of self-cleaning films, and in particular relates to a preparation method of a self-cleaning polycarbonate film which does not contain fluorine, is resistant to high temperature, has good light transmittance, is non-toxic, and has self-cleaning properties. Background technique Hydrophobic self-cleaning materials are widely used in daily life, such as self-cleaning glass, anti-fog materials, self-cleaning clothing, etc. The hydrophobic surface is mainly related to the surface energy of the material and the surface microstructure, and the surface energy of the material is related to the chemical composition of the material. Therefore, in order to obtain materials with good hydrophobic properties, it is usually necessary to prepare compounds with low surface energy. It is well known that fluorine-containing materials are widely used in the preparation of self-cleaning materials due to their low surface energy properties. For ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08J5/18C08L69/00

Inventor 赵天艺江雷周经纶朱劲松

Owner INST OF CHEM CHINESE ACAD OF SCI

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com