Preparation method of 1-amino-2-naphthol-4-sulfonic acid

A technology of naphthol and sulfonic acid, which is applied in the field of preparation of 1-amino-2-naphthol-4-sulfonic acid, can solve the problems of inflammable and explosive danger of solvent, difficult industrialization, and difficult recovery, etc., and achieves low cost, The production process is easy and the yield is improved

Inactive Publication Date: 2010-08-25

TIANJIN UNIV

View PDF3 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Aiming at the problem of using alcohol solvent in the synthesis process of 1-amino-2-naphthol-4-sulfonic acid, it is not easy to recycle, the solvent is flammable and explosive, and the cost is high, and the problem of large-scale ball milling equipment is not easy to industrialize, And the problems such as 1-amino-2-naphthol-4-sulfonic acid yield is lower, the synthetic method of 1-amino-2-naphthol-4-sulfonic acid improvement of the present invention does not adopt organic solvent, does not involve water-soluble The recovery of organic solvents, without using complex ball milling equipment, can make the yield of 1-amino-2-naphthol-4-sulfonic acid reach about 80%

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

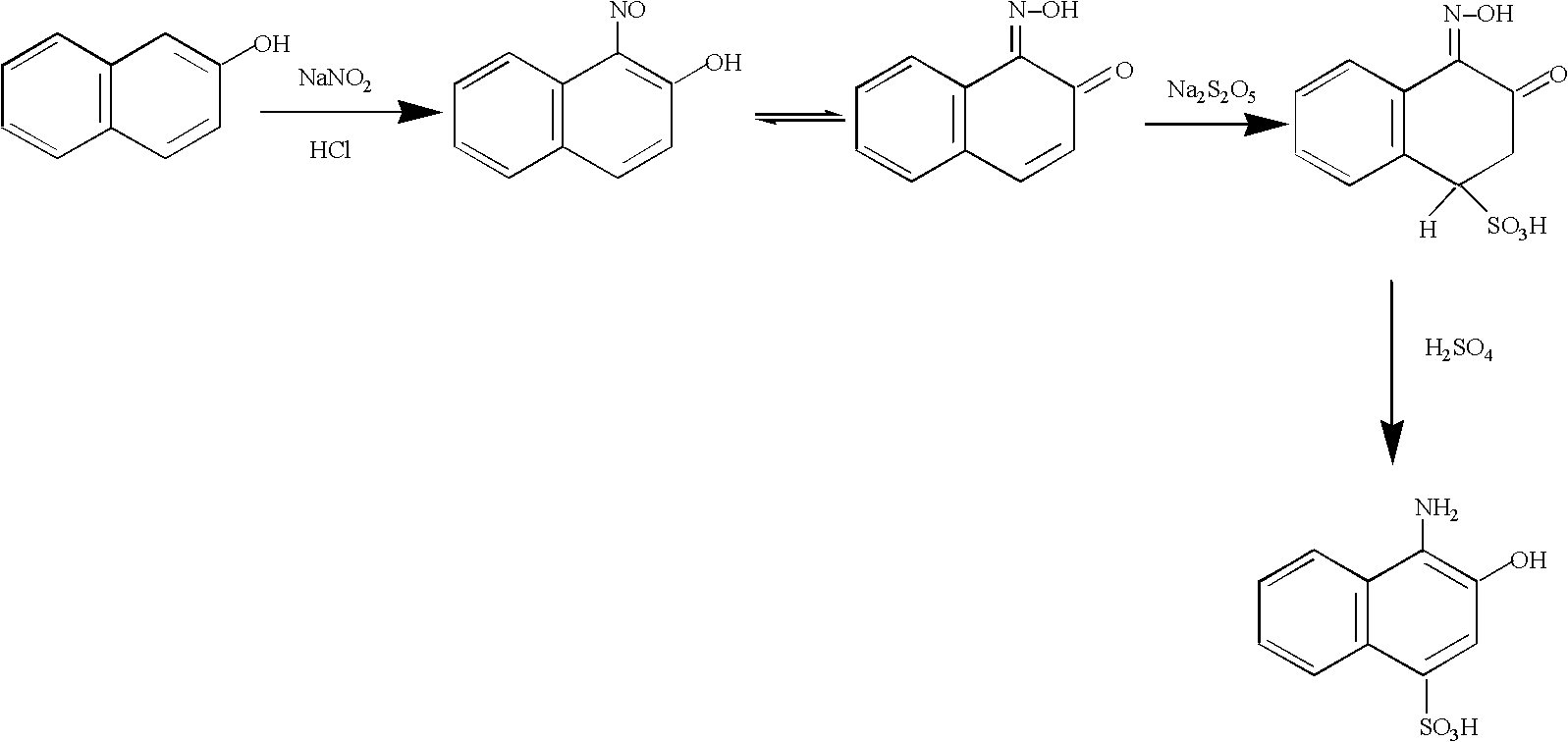

The invention provides a preparation method of 1-amino-2-naphthol-4-sulfonic acid. 2-naphthol is fully dissolved in NaOH aqueous solution which is added with dispersant and has the concentration of 5 to 10 percent into phenol sodium salt, and the weight of the added dispersant is 0.05 to 5 percent of that of 2- naphthol; 34 percent of concentrated hydrochloric acid is dripped into the solution, and the pH is controlled to be 6 to 7; 2-naphthol crystal particles are acid out; NaNO2 aqueous solution is added into 2-naphthol suspension, and the use amount of sodium nitrite is 50 to 55 percent of the weight of 2- naphthol; and then 34 percent of concentrated hydrochloric acid is added in, and the use amount of the concentrated hydrochloric acid is 65 to 75 percent of the weight of 2-naphthol; and nitrosation is carried out, the nitrosation temperature is 0 to 5DEG C, and the reaction time is 2 to 6h. By adding effective dispersant in a nitrosation stage, the preparation method of the 1-amino-2-naphthol-4-sulfonic acid can significantly improve the yield of the 1-amino-2-naphthol-4-sulfonic acid, has little addition of the dispersant, does not need to add extra equipment, reduces the cost of the 1-amino-2-naphthol-4-sulfonic acid, is easy for industrialization, and has very good economic benefit.

Description

technical field The invention belongs to the field of synthesis of dye intermediates, and particularly proposes a preparation method of 1-amino-2-naphthol-4-sulfonic acid. Background technique 1-amino-2-naphthol-4-sulfonic acid, also referred to as 1,2,4-acid, is an important dye intermediate, which can be used to prepare acid mordant dyes, acid complex dyes, neutral dyes, etc. It is widely used for analyzing phosphate and calcium salt, and the market demand is large. There are many processes for preparing 1-amino-2-naphthol-4-sulfonic acid in the literature, but the process conditions and results are all different. A better synthetic route is to prepare 1-amino-2-naphthol-4-sulfonic acid by nitrosation of 2-naphthol, addition of sulfite, and acidic reductive transposition. The specific reporting process includes: (1) nitrosation of 2-naphthol in an alcoholic solvent (such as ethanol) to obtain 1-nitroso-2-naphthol, then addition with sodium bisulfite, reduction in sulfuri...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07C309/50C07C303/22C07C303/20C07C207/04C07C201/00

Inventor 张天永何萌刘旭

Owner TIANJIN UNIV

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com