Traveling wave type ultrasound reaction vessel

An ultrasonic reactor, traveling wave technology, applied in the chemical/physical/physicochemical process of energy application, mechanical oscillation water/sewage treatment, etc., can solve the problems of uneven acoustic treatment and low utilization rate of acoustic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

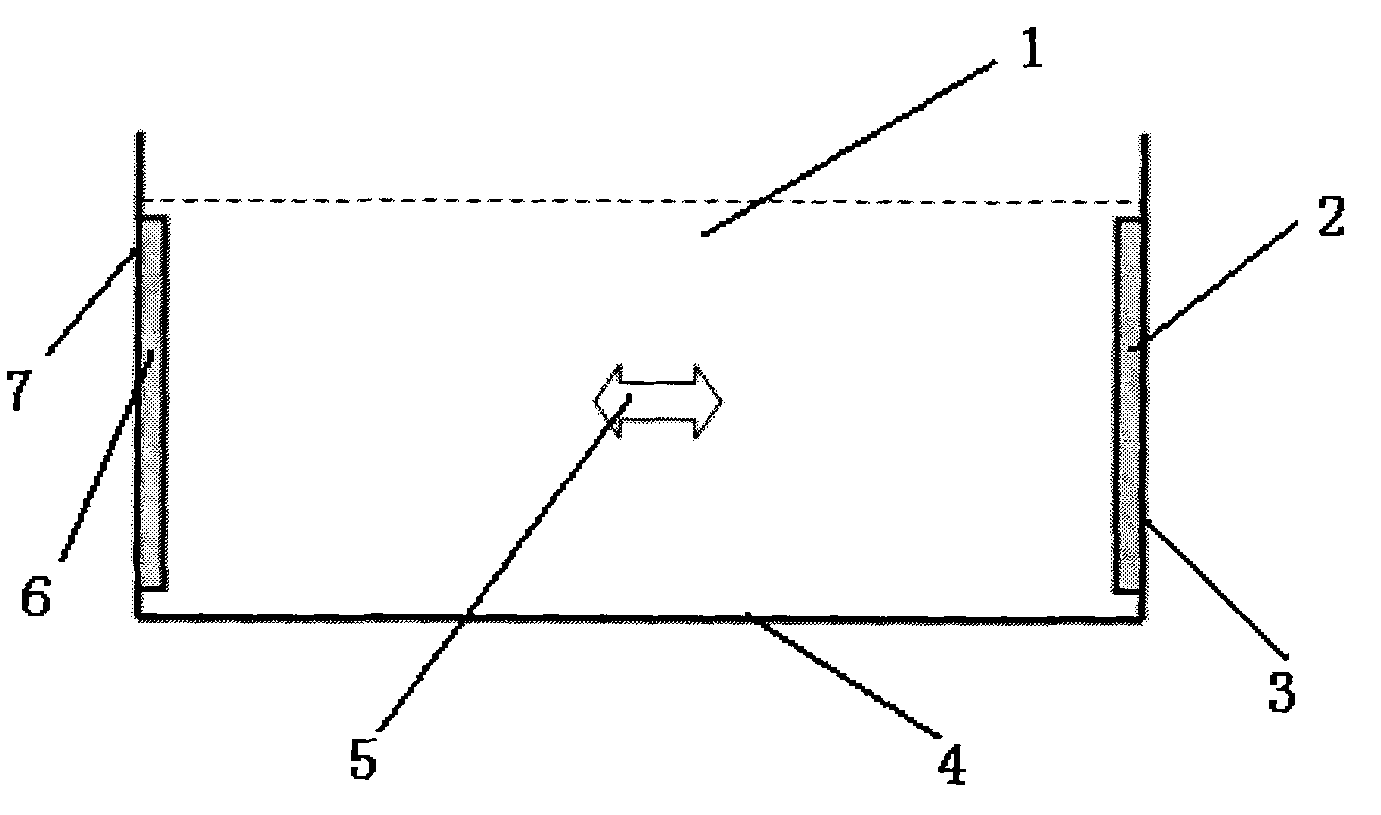

[0016] The ultrasonic reactor of Embodiment 1 is shown in FIG. 1 .

[0017] Treated water is contained in the rectangular metal box 3 of the ultrasonic reactor with a pair of submerged flat-plate ultrasonic transducers. The first immersion-type flat-panel ultrasonic transducer and the second immersion-type flat-panel ultrasonic transducer are respectively fixed on the first wall 3 and the second wall 7 of the box 1 . The first transducer 2 and the second transducer 6 are planar ultrasonic transducers, and the radiation surface 8 of the first transducer and the radiation surface 9 of the second transducer face each other. The first and second ultrasonic transducers have the same structure, size and material. The AC drive voltages applied to the first and second transducers have the same frequency f, amplitude and time phase difference of 90°. The distance d between the sound radiating surfaces of the first and second transducers satisfies d=(2m+1)c / (4f), where m=8 and c is th...

Embodiment 2

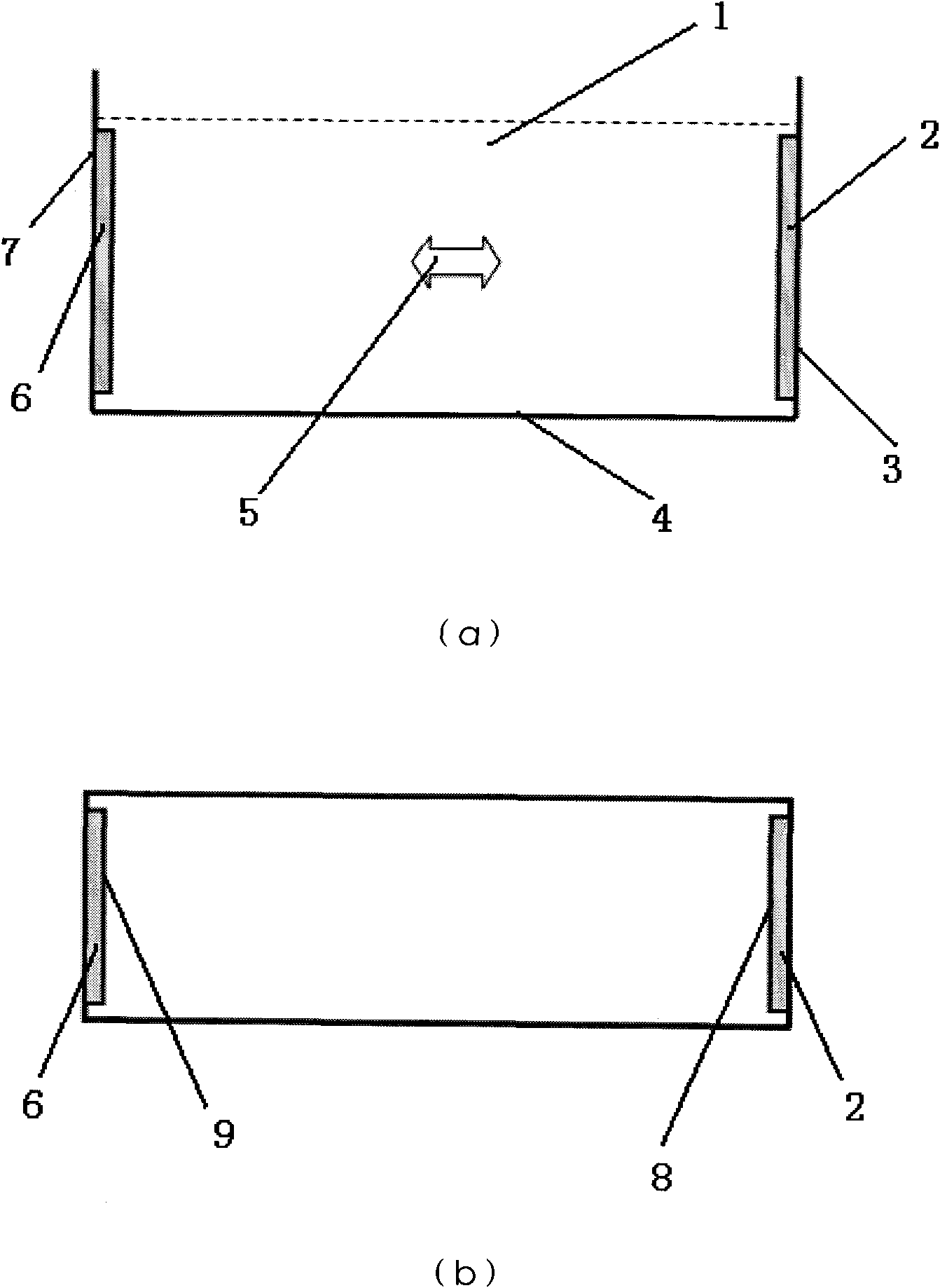

[0020] The ultrasonic reactor of Example 2 is shown in FIG. 2 .

[0021] The rectangular metal box of the ultrasonic reactor with two pairs of submerged flat-panel ultrasonic transducers contains the water to be treated. Two first immersion-type flat-panel ultrasonic transducers and two second immersion-type flat-panel ultrasonic transducers are respectively fixed on the first wall 3 and the second wall 7 of the box 1 . Radiation surfaces of the first transducer and the second transducer of each pair of transducers face each other. The first and second ultrasonic transducers have the same structure and dimensions. The AC driving voltages applied to the first and second transducers have the same frequency f, amplitude and time phase difference of 90°. The distance d between the sound radiating surfaces of the first and second transducers satisfies d=(2m+1)c / (4f), where m=8 and c is the sound velocity of water (=1500m / s). Under the above conditions, the ultrasonic traveling w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com