Portable gasoline economizer

A fuel-saving and portable technology, applied in packaging, distribution devices, transportation and packaging, etc., can solve the problems of difficult control of gasoline consumption, endangering employees' health, and inability to recycle gasoline, so as to eliminate fire hazards and protect employees' health. Healthy, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

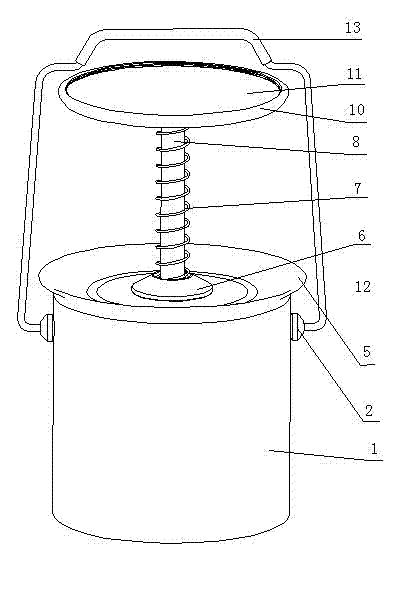

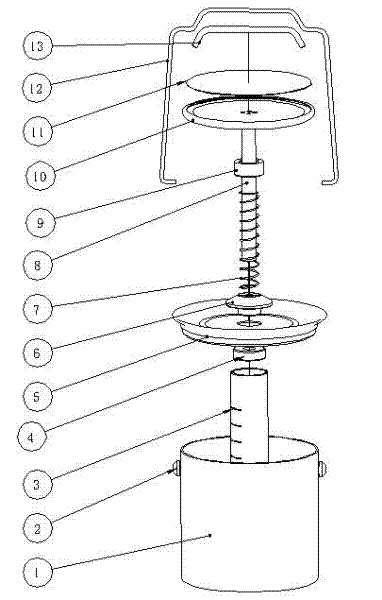

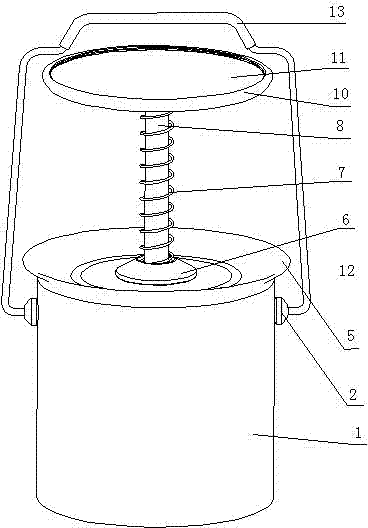

[0011] exist figure 1 , figure 2 Among them, the present invention is provided with a cylindrical oil reservoir 1 and a cover plate 5, a tubular oil delivery device 3 is fixed inside the oil storage device 1, a cut is processed on the pipe wall of the oil delivery device 3, and a piston is arranged inside the oil delivery device 3. 4. A guide sleeve 6 is installed at the through hole in the middle of the cover plate 5. The lower end of the oil guide tube 8 passes through the guide sleeve 6 and is screwed together with the screw hole in the middle of the piston 4. The upper part of the oil guide tube 8 is fixed with a nut 9, and the oil guide tube 8 The upper sleeve is equipped with a spring 7, the lower end of the spring 7 is positioned in the slot of the guide sleeve 6, the upper end of the spring 7 is positioned under the nut 9, so that the spring 7 is limited between the nut 9 and the cover plate 5, and the top end of the oil guide tube 8 is screwed together In the screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com