Pneumatic tire

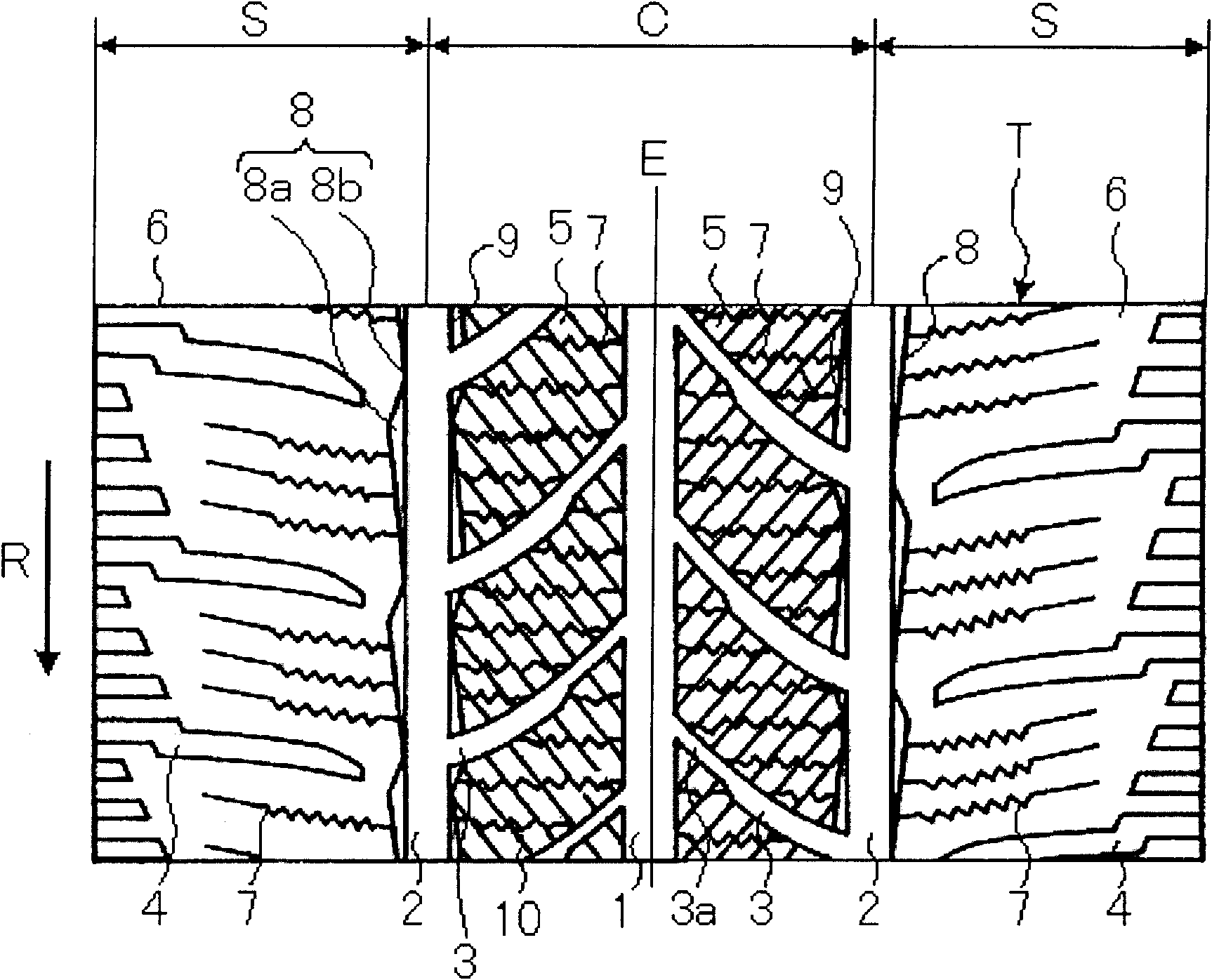

A pneumatic tire, tire circumferential technology, applied in tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve the problems of tire snow performance reduction, snow traction reduction, etc., to improve snow performance The effect of improving ground performance, improving stability, and improving uneven wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

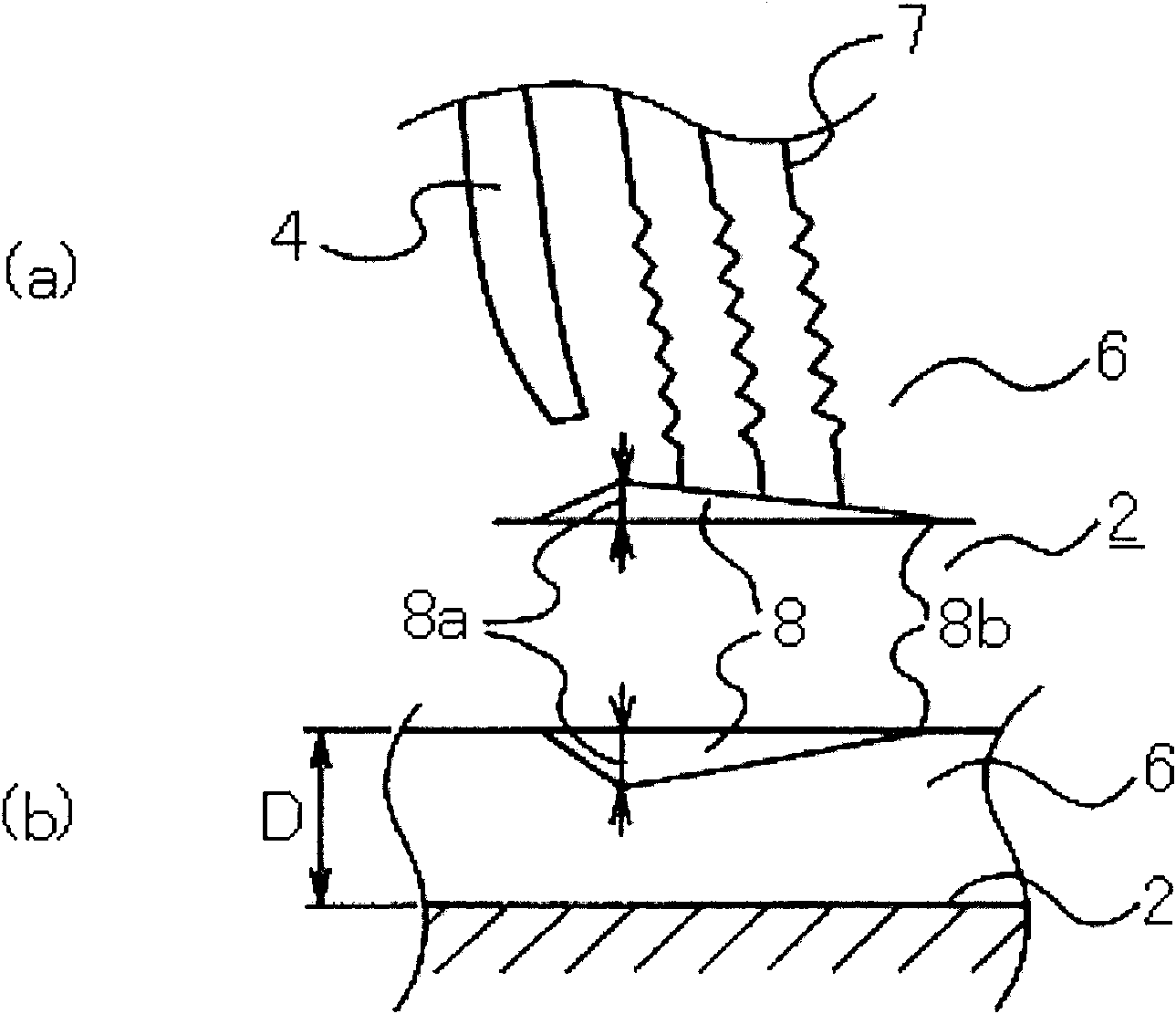

Method used

Image

Examples

Embodiment 1

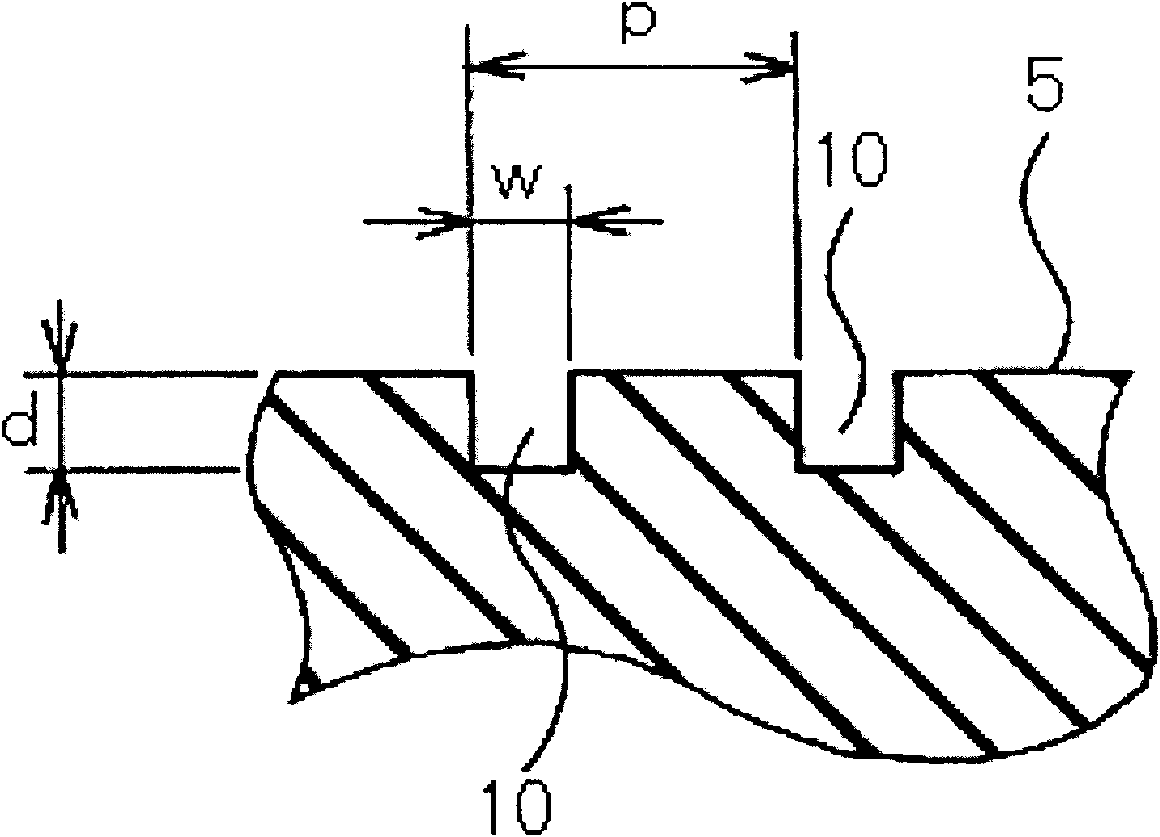

[0057] Examples 1 to 7 are examples in which the number of pitches of each chamfered portion is 3 pitches, and the largest chamfered portion is arranged in the middle of the sipe groove. Furthermore, in Example 1, the depth of the maximum chamfered portion was 20% of the maximum main groove depth. In Example 2, the depth of the maximum chamfered portion was 30% of the maximum main groove depth. In Example 3, the depth of the maximum chamfered portion was 40% of the maximum main groove depth. In Example 4, the depth of the largest chamfered portion was 50% of the maximum main groove depth. In Example 5, the depth of the maximum chamfered portion was 60% of the maximum main groove depth. In Example 6, the depth of the maximum chamfered portion was 70% of the maximum main groove depth. In Example 7, the depth of the maximum chamfer was 45% of the maximum main groove depth.

[0058] In addition, Examples 8 to 11 are examples in which the depth of the maximum chamfer is 45% of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com