Crawler-type pile frame and method for mounting same

A crawler type, pile frame technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of complexity of operation process, slippage, lack of power, etc., to improve reliability and emergency ability, simple installation process , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

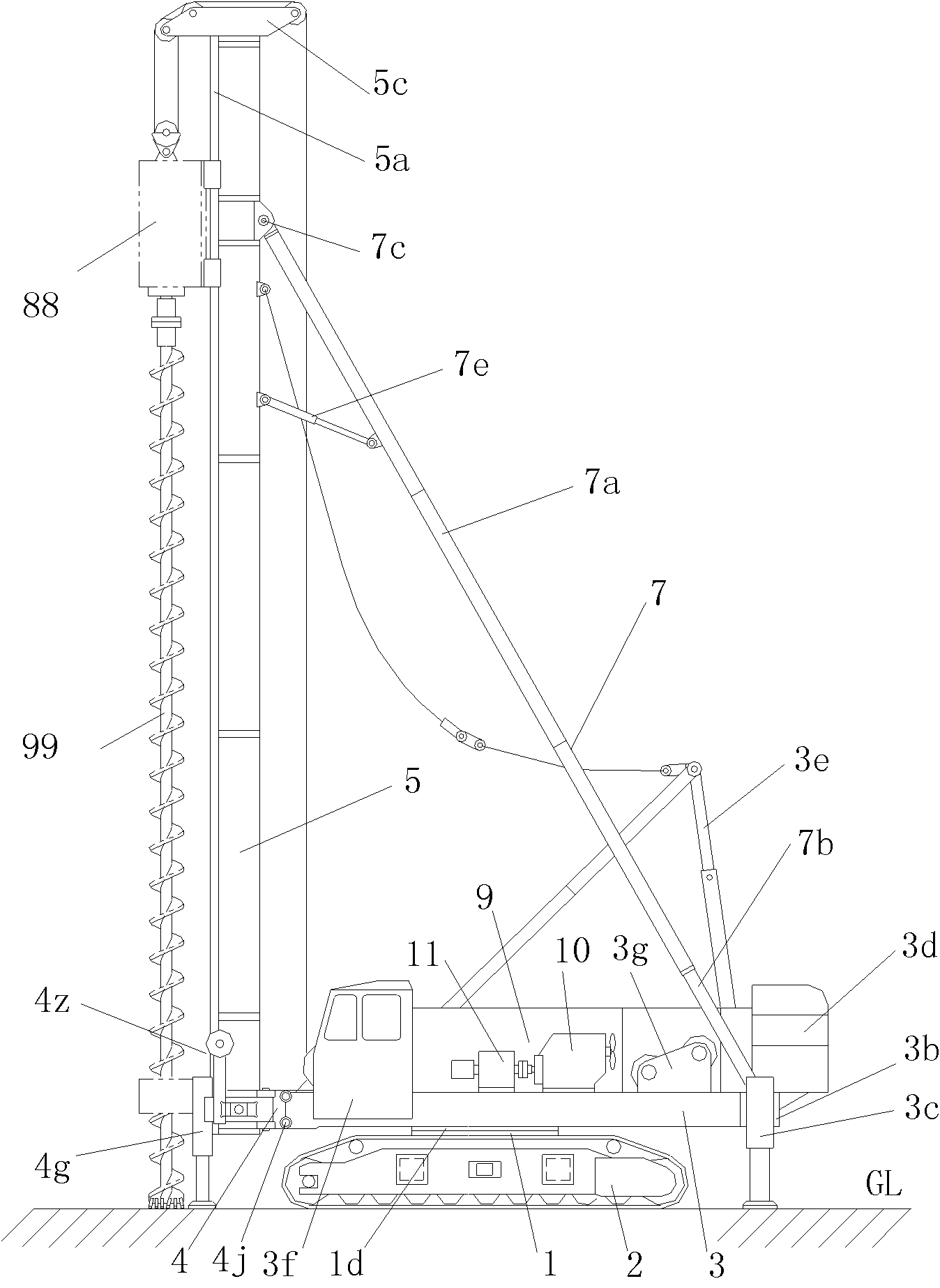

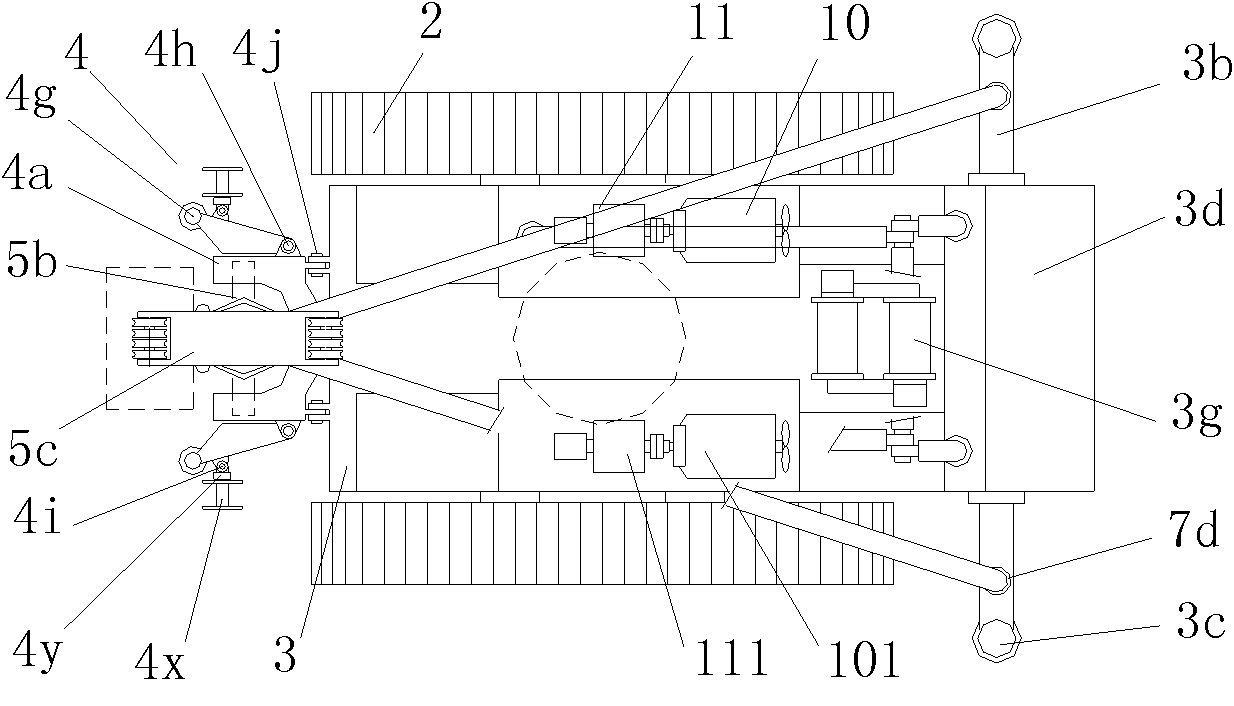

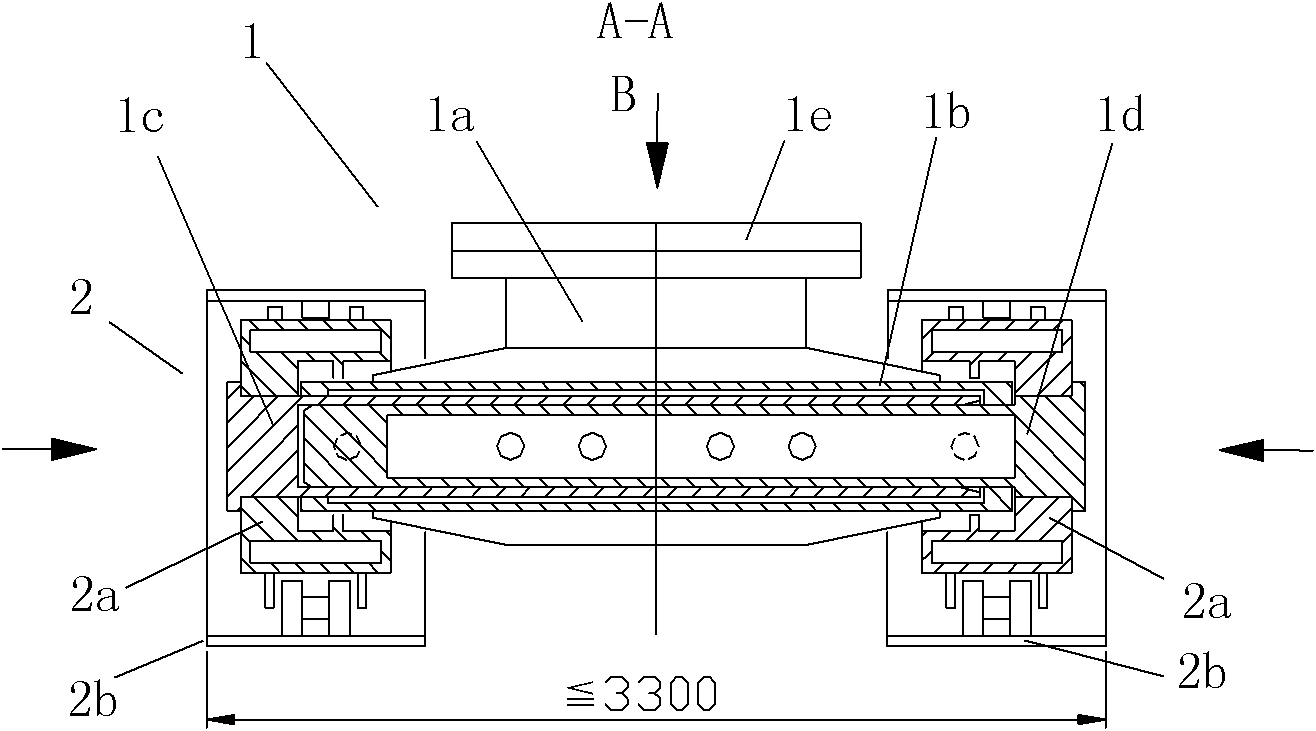

[0044] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 13 and Figure 14 , the chassis 1 is mainly composed of a base 1a, a hollow sliding seat 1b, a hollow sliding beam 1c, a sliding beam 1d, a rotating support 1e and a crawler walking device 2; , reducer 2d and driving wheel 2e; one end of the hollow sliding beam 1c and sliding beam 1d is respectively fixedly connected with the crawler frame 2a of the crawler traveling device 2, and the other end is movably inserted into the hollow sliding seat 1b, and is hinged through one end On the base 1a, the other end of the hydraulic cylinder 1f hinged on the crawler bracket 2a expands and contracts, and the crawler running devices 2 on both sides can shrink inward or widen outward. Fix the hollow sliding beam 1c and sliding beam 1d with the hollow sliding seat 1b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com