Method and device for preventing scaling of reactor and simultaneously purifying biogas

A reactor, anaerobic reactor technology, applied in water softening, waste fuel, anaerobic digestion treatment, etc., can solve problems such as blockage, reactor failure, and reduced mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: When the present invention treats organic waste water containing high concentration of calcium ions, in order to prevent fouling of the reactor and purify biogas at the same time, it is mainly realized through its system device. This system device is the key or key point of the present invention.

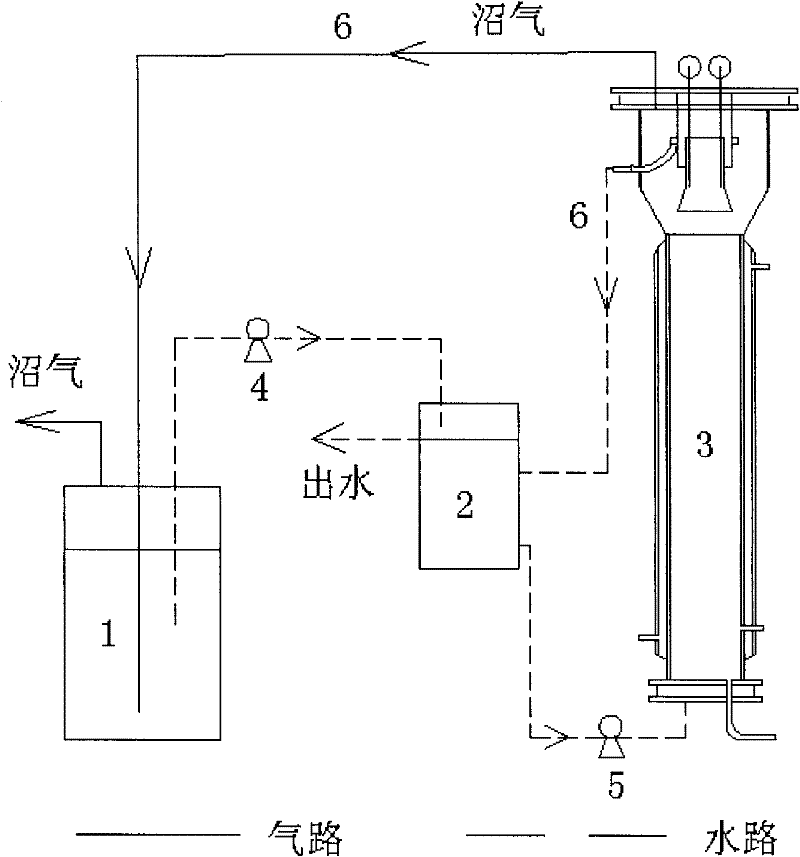

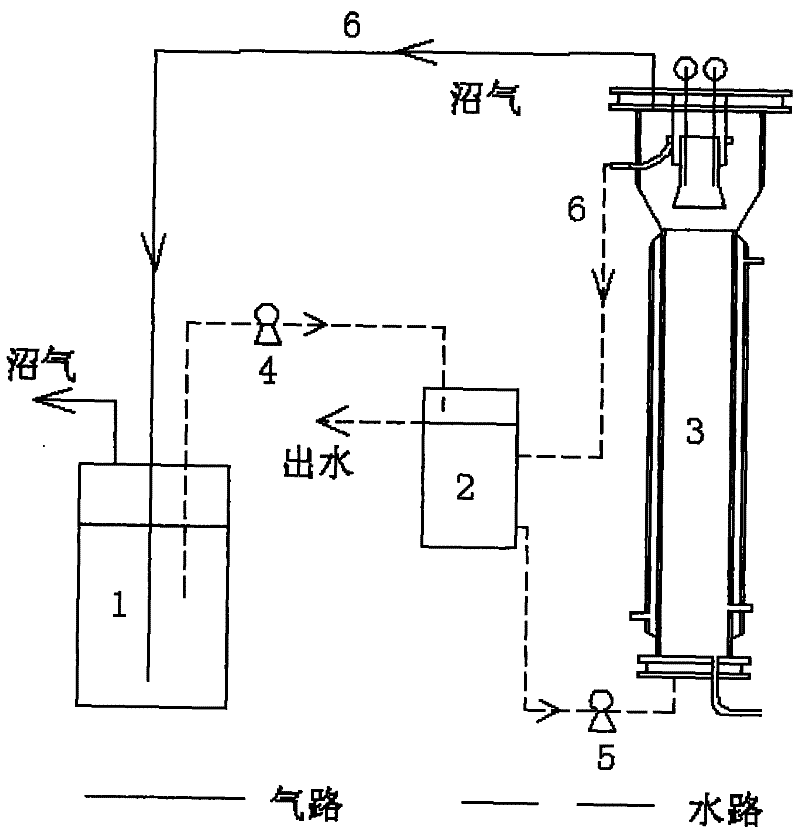

[0020] see figure 1 , The system device in this embodiment includes: a storage tank 1 containing organic waste water with a high concentration of calcium ions, a buffer tank 2, an anaerobic reactor 3, a feed pump 4, a circulation pump 5, and a pipeline 6. The storage tank 1 is provided with a pipeline 6 connected to the biogas outlet at the top of the anaerobic reactor 3; in addition, the waste water storage tank 1 passes through the pipeline through the feed pump 4, the buffer tank 2, the circulation pump 5 and the anaerobic reactor The waste water inlets at the bottom of 3 are connected; a part of the waste water circulation return line is arranged on the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com