Method for using carbide slag for material circulation system in carbide industry

A circulation system and carbide slag technology, applied in the petroleum industry, carbide, solid waste removal, etc., can solve problems that cannot be solved fundamentally, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

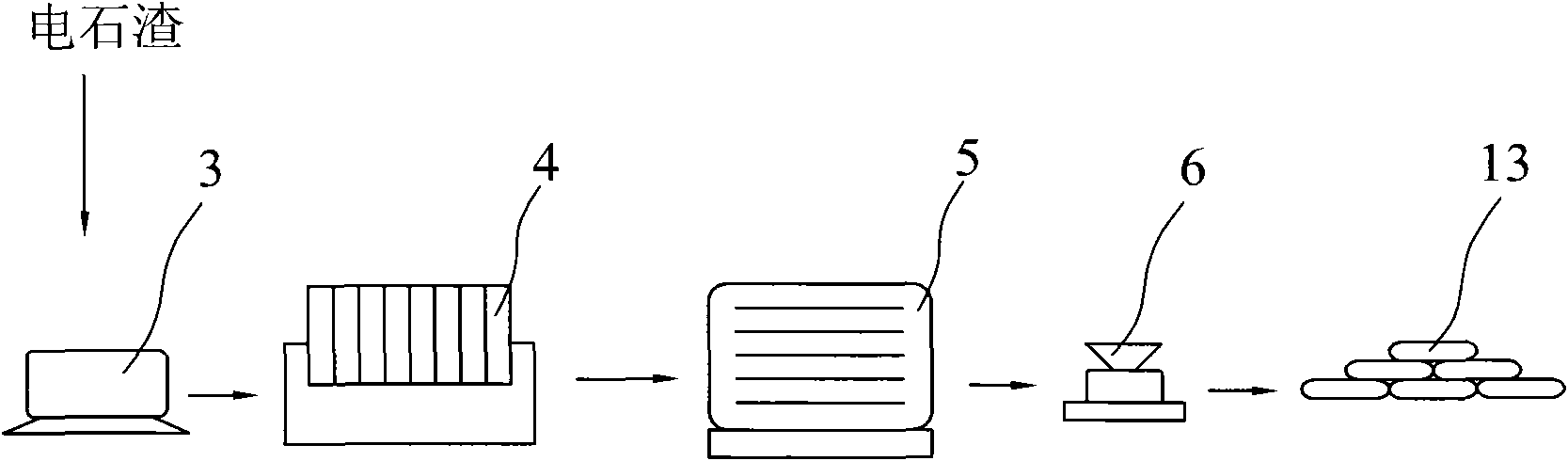

[0022] Embodiment 1: 1000 kg of newly discharged calcium carbide slag is dehydrated by a centrifuge (3) to form dry calcium carbide slag with a water content of 20%, and then sent to a pressure forming machine (4) for extrusion molding, and then put into a calciner Carry out calcining in (5), make calcium carbide slag strong dehydration decomposition, and calcining temperature is 580 ℃; Calcining 4.5 hours, after cooling, only 58% pure substance remains, take out and obtain 580kg calcium oxide product (13), The calcium oxide product (13) is taken out, and after being pulverized by the pulverizer (6), it is sent to the calcium carbide calcining workshop for recycling.

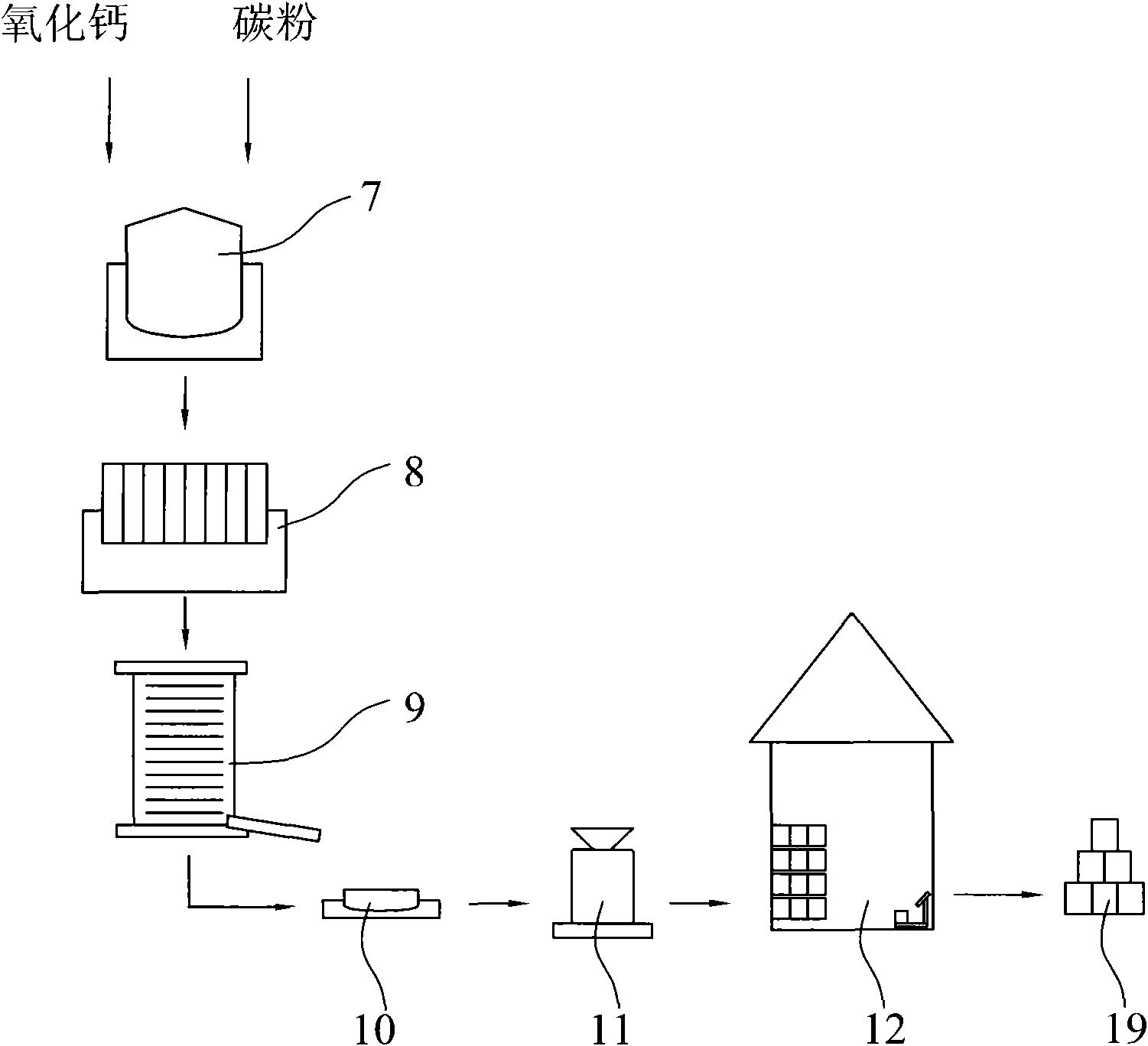

[0023] Put 500kg of calcium oxide calcined in the calcium carbide calcination workshop and coke powder into the agitator (7) according to the ratio of pure substance mass to 1:0.44 and stir evenly, then press and form in the pressure molding machine (8), and feed into Carry out calcining in a closed electric fur...

Embodiment 2

[0024] Embodiment 2: 1000kg of newly discharged calcium carbide slag is dehydrated by a centrifuge (3) to form dry calcium carbide slag with a water content of 30%, and then sent to a pressure molding machine (4) for extrusion molding, and then put into a calciner Carry out calcining in (5), make calcium carbide slag strong dehydration decomposition, and calcining temperature is 650 ℃; Calcining 6 hours, after cooling, only 54% pure substance remains, take out and obtain 540kg calcium oxide product (13), The calcium oxide product (13) is taken out, and after being pulverized by the pulverizer (6), it is sent to the calcium carbide calcining workshop for recycling.

[0025] Put 500kg of calcined calcium oxide and coke powder calcined in the calcium carbide calcination workshop into the agitator (7) according to the ratio of pure substance mass to 1:0.84 and stir evenly, then press and form in the pressure molding machine (8), and feed into Carry out calcining in a closed electr...

Embodiment 3

[0026] Embodiment 3: 1000 kg of newly discharged calcium carbide slag is dehydrated by a centrifuge (3) to form dry calcium carbide slag with a water content of 25%, and then sent to a pressure forming machine (4) for extrusion molding, and then put into a calciner Carry out calcining in (5), make calcium carbide slag strong dehydration decompose, calcining temperature is 600 ℃; Calcining 5 hours, after cooling, only 56% pure substance remains, take out and obtain 560kg calcium oxide product (13), The calcium oxide product (13) is taken out, and after being pulverized by the pulverizer (6), it is sent to the calcium carbide calcining workshop for recycling.

[0027] Put 500kg of calcium oxide calcined in the calcium carbide calcination workshop and coke powder into the agitator (7) according to the ratio of pure substance mass to 1:0.64 and stir evenly, then press and form in the pressure molding machine (8), and feed into Carry out calcining in a closed electric furnace (9), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com