Sorting and grading device of pulsating liquid-solid fluidized bed and method thereof

A technology of fluidized bed and pulsating water flow, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of reduced sorting efficiency, equipment wear, large power consumption, etc., to facilitate automatic discharge and prevent deposition The effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

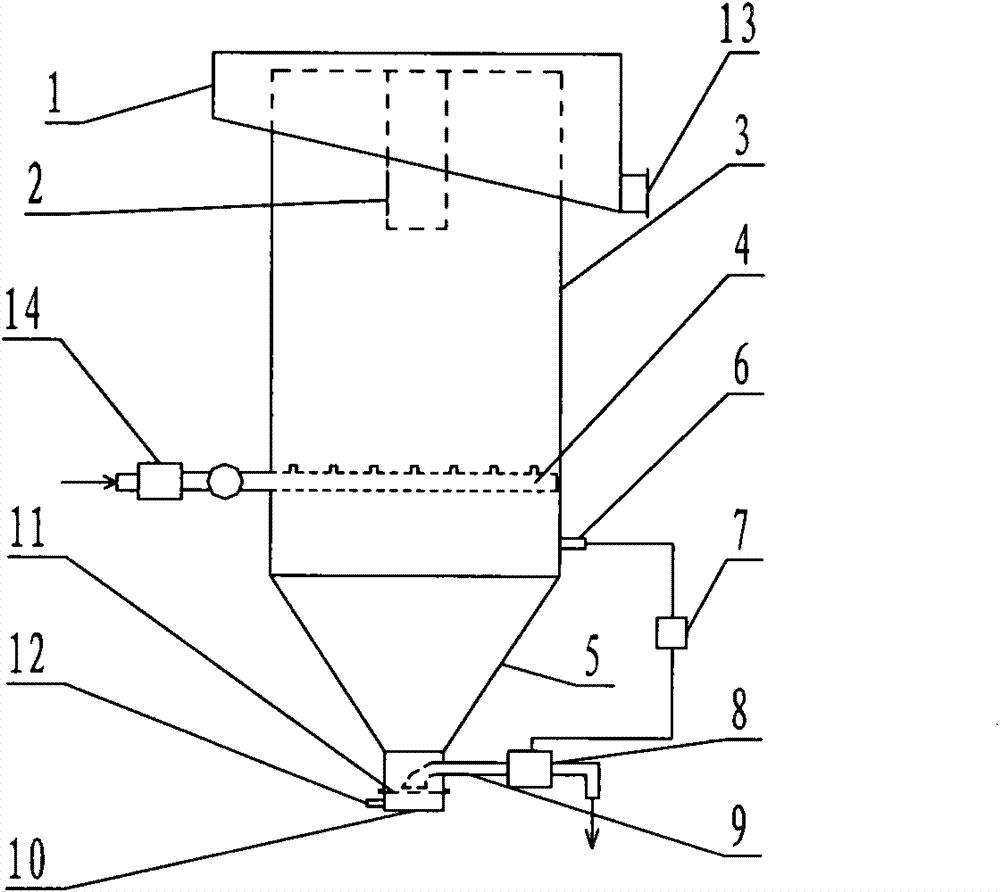

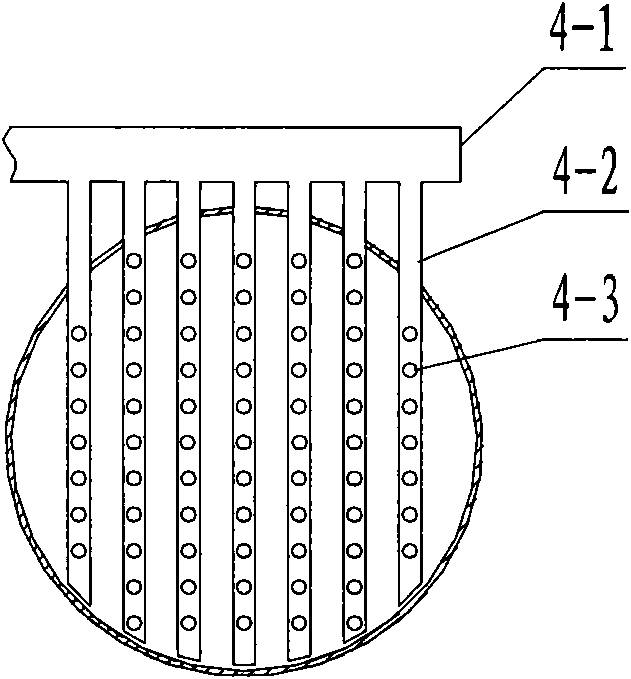

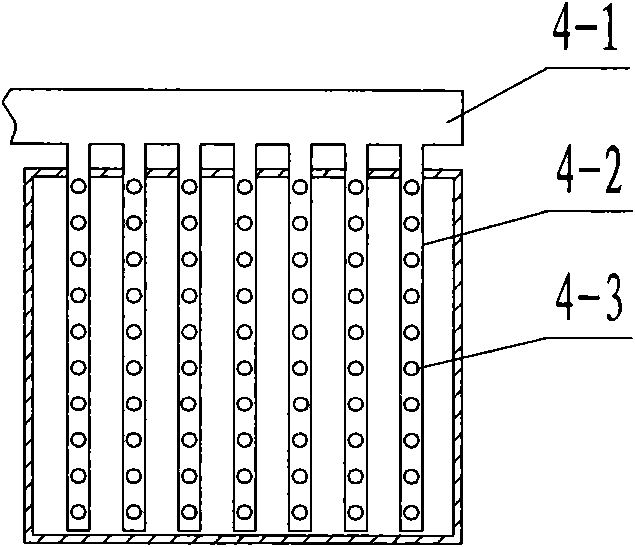

[0017] Such as figure 1 As shown, the pulsating liquid-solid fluidized bed sorting and grading equipment of the present invention is mainly composed of a central feeding pipe 2, a sorting barrel 3, a pulsating water flow distributor 4, a pulsating water flow generator 14, a light product overflow tank 1, The heavy product collection bottom cone section 5, the heavy product discharge pipe 9, the heavy product discharge fluidized chamber 10, the sensor 6, the programmable controller 7 and the underflow discharge automatic control actuator 8 constitute. The section of the sorting barrel 3 and the heavy product collection bottom cone section 5 is circular or rectangular, the heavy product collection bottom cone section 5 is set at the lower end of the sorting barrel body 3, and the light product overflow tank 1 is set at the sorting barrel body 3 The upper par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com