Method for removing micas in nephelite by using cyclone

A cyclone and nepheline technology, which is applied in the field of removing mica in nepheline by using a cyclone, can solve the problems of high mica content, loss of use value, failure to remove mica, etc., achieve high recovery rate and reduce overgrinding phenomenon , conducive to the effect of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

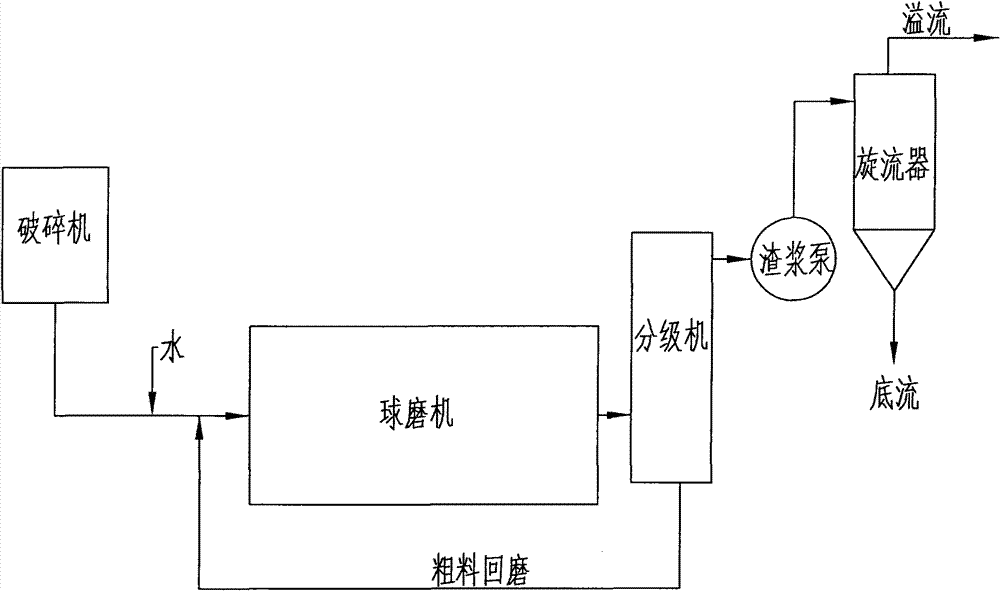

[0038] Such as figure 1 Shown utilizes cyclone to remove the method for the mica in nepheline, comprises the following steps:

[0039] (1), carry out pretreatment to nepheline raw ore, process ore-forming slurry, ore slurry is made up of nepheline powder, mica powder and water;

[0040] Carry out pretreatment (wet grinding) to nepheline raw ore, comprise the following steps:

[0041] ①. Crushing the nepheline raw ore through a crusher;

[0042] ② Add water after crushing;

[0043] ③. Grinding by ball mill after adding water;

[0044] ④, after grinding, classify by classifier;

[0045] ⑤. Take samples from the fine material outlet of the classifier, sieve through a square hole experimental water sieve to detect the fineness of the mineral powder particles, and use an electron microscope to detect the maximum particle size of the sieve, and adjust the speed and feeding amount of the classifier according to the test results;

[0046] ⑥. The pulp with small ore particle size ...

Embodiment 2

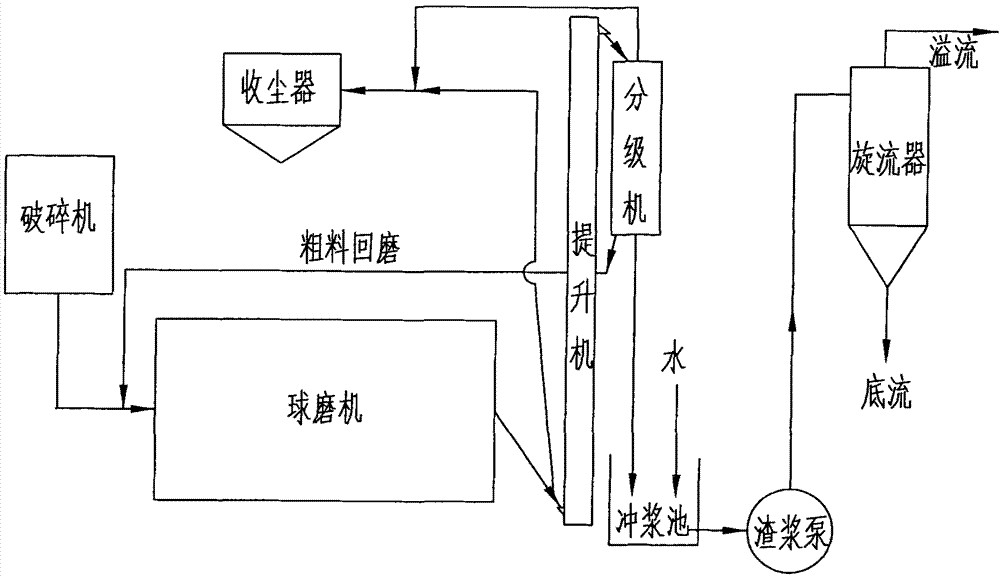

[0066] Such as figure 2 Shown utilizes cyclone to remove the method for the mica in nepheline, comprises the following steps:

[0067] (1), carry out pretreatment to nepheline raw ore, process ore-forming slurry, ore slurry is made up of nepheline powder, mica powder and water;

[0068] Carry out pretreatment (dry grinding) to nepheline raw ore, comprise the following steps:

[0069] ①. Crushing the nepheline raw ore through a crusher;

[0070] ②, after pulverization, it is ground by a ball mill;

[0071] ③. After grinding, it is sent to the classifier through the elevator;

[0072] ④, classifier for grading;

[0073] ⑤. Take samples from the fine material outlet of the classifier, sieve through a square hole experimental water sieve to detect the fineness of the mineral powder particles, and use an electron microscope to detect the maximum particle size of the sieve, and adjust the speed and feeding amount of the classifier according to the test results;

[0074] ⑥. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com