Bearing device for wheel

A bearing device and wheel technology, applied in the directions of bearings, axles, wheels, etc., can solve the problems of poor component management, large number of components, and poor workability, and achieve the effects of stabilizing torque, improving strength, and inhibiting looseness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

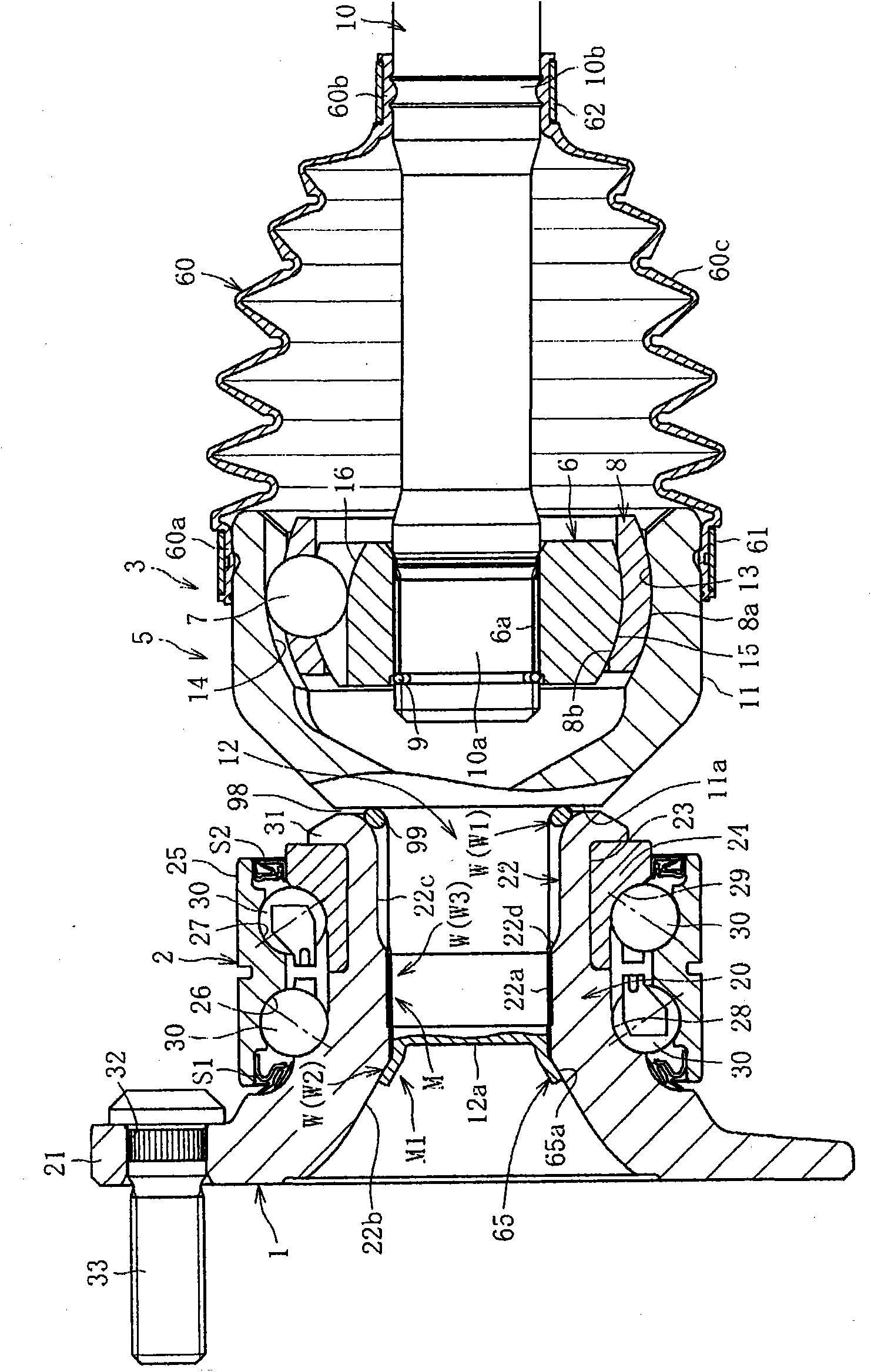

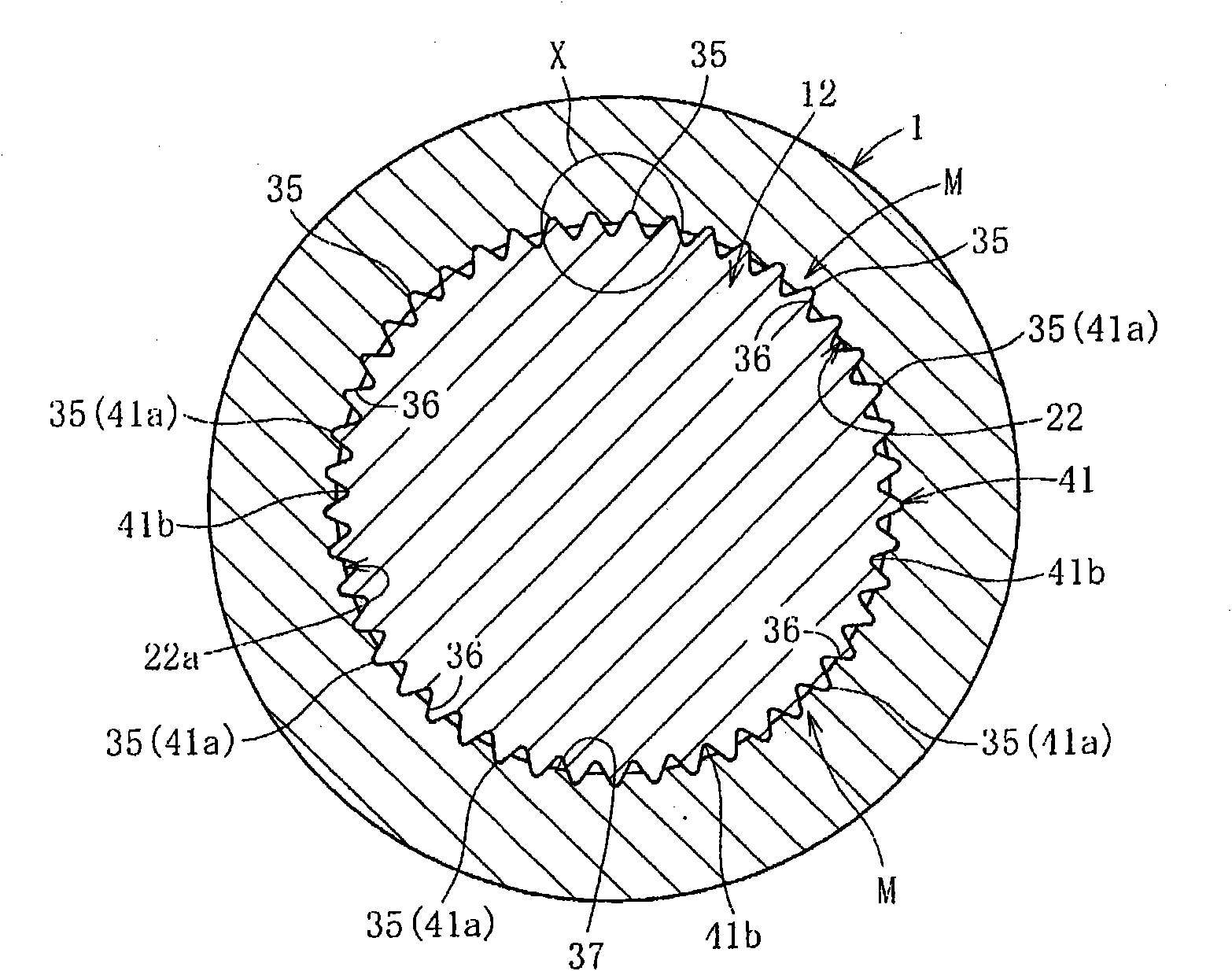

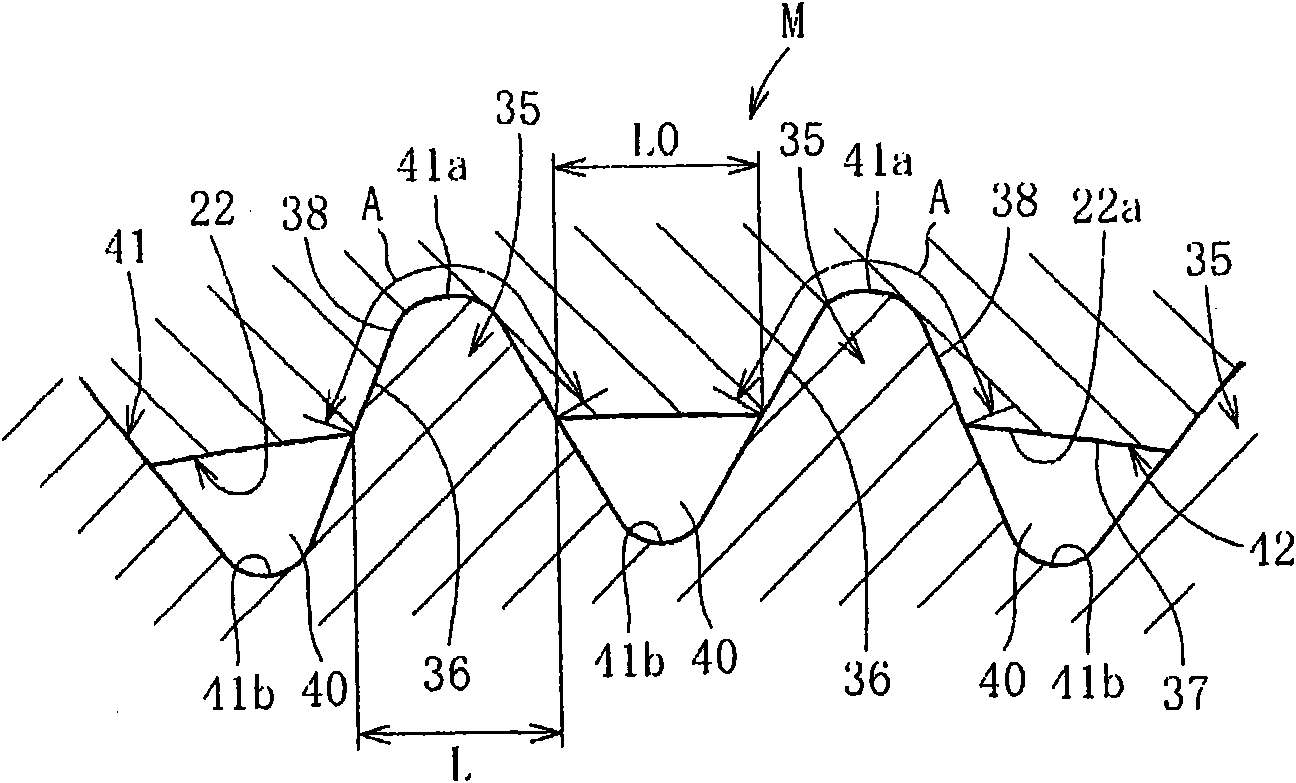

Embodiment 1

[0226] A male spline with a modulus of 0.48 and a number of teeth of 58 is formed on the shaft portion 12, and the press-fit load is measured when the cross angle θ1 is changed, where the cross angle θ1 is defined as the distance between the end surface 35a and the axis of the convex portion 35 at the start of press-fit. angle formed. In addition, the formability of the concave-convex fitting structure M when the intersection angle θ1 was changed was also evaluated. Figure 37 The measurement results of press-fit load are shown in , Figure 41 The evaluation results of formability are shown.

[0227] Depend on Figure 37 It can be seen that when the intersection angle θ is smaller than 50°, the press-fitting load increases. In addition, when the intersection angle θ is larger than 110°, the spline end surface is likely to be chipped, and when the chip is formed, the formability of the concave-convex fitting structure M deteriorates sharply, and the press-fitting load increa...

Embodiment 2

[0230] A male spline 41 having a modulus of 0.48 and a number of teeth of 59 was formed on the shaft portion 12, and Δd / 2h was varied to measure the press-fit load. Furthermore, a torsional strength test was performed on each of the concave-convex fitting structures, and the formability of the concave-convex fitting structure M was evaluated. Figure 38 The measurement results of press-fit load are shown in , Figure 39 shows the evaluation results of the torsional strength test, Figure 42 The evaluation results of the formability of the concave-convex fitting structure are shown in .

[0231] Depend on Figure 38 with Figure 39 It can be seen that when Δd / 2h exceeds 0.86, the press-fitting load increases rapidly and the torsional strength decreases. In addition, when Δd / 2h is 0.3 or less, the torsional strength decreases. Therefore, it is preferable that 0.3 Figure 42 It can be seen that the formability of the concave-convex fitting structure M is good when Δd / 2h is in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com