Fastening device

A fastening device and fastener technology, applied in the direction of friction-clamped detachable fasteners, connecting components, mechanical equipment, etc., can solve the problems of difficult disassembly, difficult loosening of wedges, etc., and achieve convenient operation and rapid disassembly. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

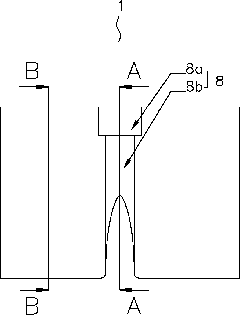

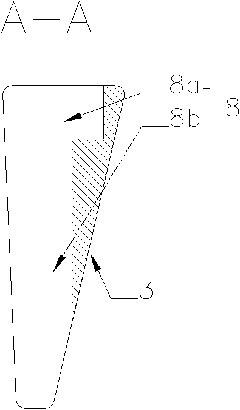

[0024] Such as figure 1 As shown, a fastening device includes two wedges that will be squeezed and fixed in the matrix 27 by the fastener 28. The slopes of the two wedges overlap and are tightly squeezed by mutual sliding between the two. Firmware 28, one of the two wedges is connected with a pressing dismounting part, and the pressing dismounting part presses on another wedge or the substrate, and the rotation of the pressing dismounting part drives the wedge connected to it to move, and the two wedges are loosened. Squeeze between wedges. The two wedges are respectively the first wedge 1 and the second wedge 2. The present invention defines the big head of the first wedge 1 and the second wedge 2 as the top and the small head as the bottom. As can be seen from the figure, this In the embodiment, the large end of the first wedge 1 is on the top, and the small end of the second wedge 2 is on the top.

[0025] Such as figure 1 , 2 , 3, 4, and 5, wherein the first wedge 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com