Bi-component composite fiber and preparation method thereof

A composite fiber and two-component technology, applied in fiber processing, conjugated synthetic polymer artificial filament, filament/thread forming, etc., can solve the problem of weak physical bond strength, inability to smoothly perform needle punching, and excessive softness of nylon And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Take 22 parts of polyethylene terephthalate chips and dry them at 170°C, put them into a polyester spinning screw extruder to melt and knead at 280°C, and add 3 parts of flux during the kneading, the flux is polyparaffin Butylene glycol phthalate; 75 parts of polycaprolactam slices were dried at 85°C and put into a polyamide spinning screw extruder at 270°C for melting and kneading.

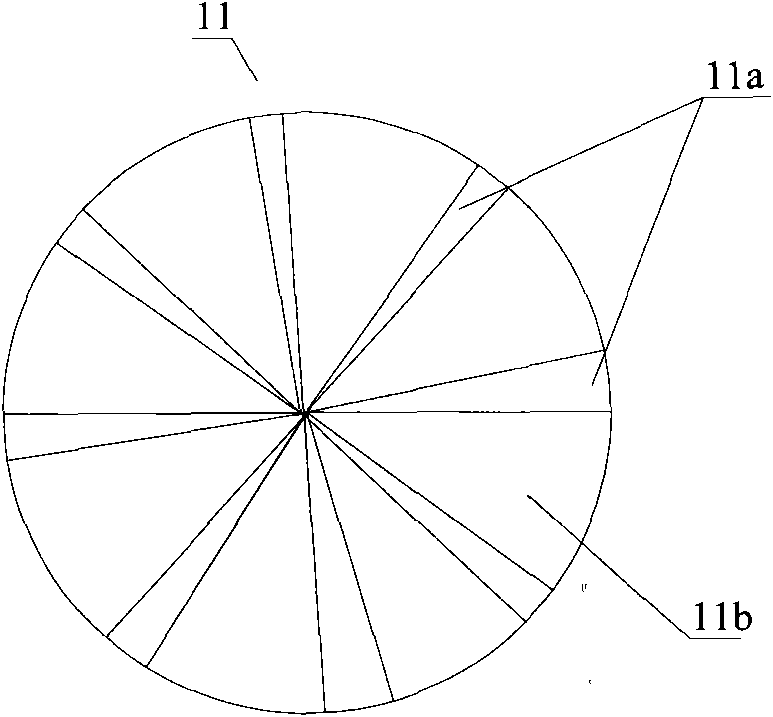

[0054] The mixed products of two screw extruders were subjected to figure 2 The 8-split spinneret is extruded to obtain as-spun fibers. The following examples all use this spinneret to extrude to obtain 8-split as-spun fibers. The lobes between the fiber skeletons are composed of polyethylene terephthalate and the lobes are polycaprolactam;

[0055] Then, the as-spun fiber is cooled and shaped by an annular cooling and blowing device, the cooling temperature is 22°C, and then oiled by a tanker on both sides. The oil agent is 4wt% silicone emulsion, and the oil content of the fiber after ...

Embodiment 2 to Embodiment 5

[0058] Use polyester, flux, polyamide identical with embodiment 1 in above-mentioned four embodiments, concrete process parameter is shown in Table 2:

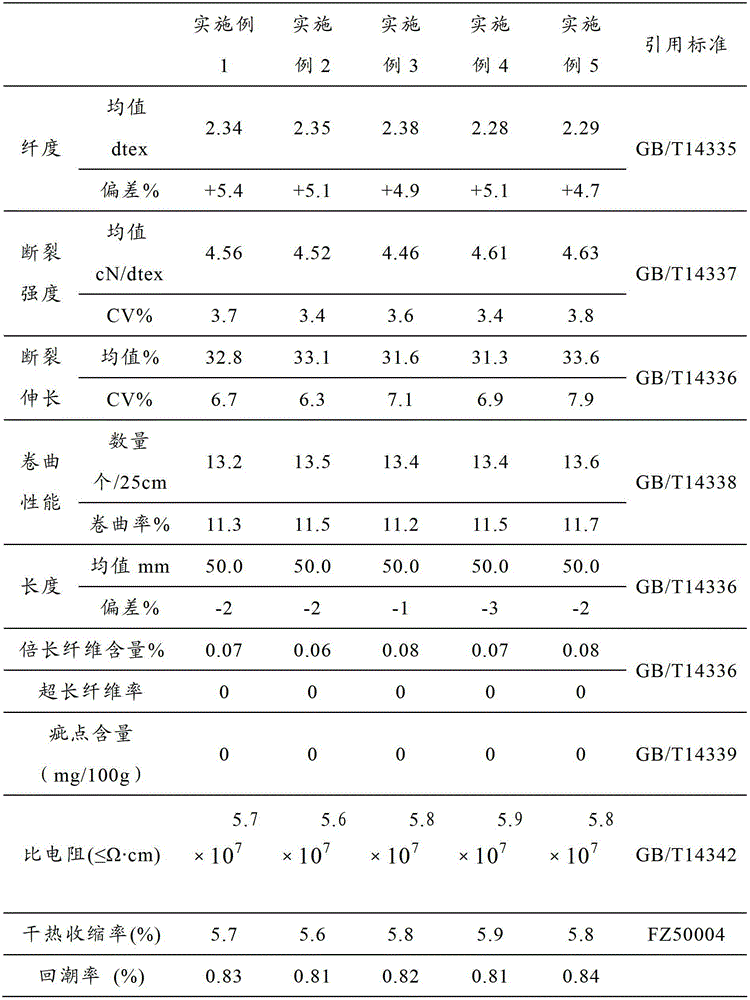

[0059] Measure the performance of Examples 2 to 5 and list them in Table 1.

Embodiment 6

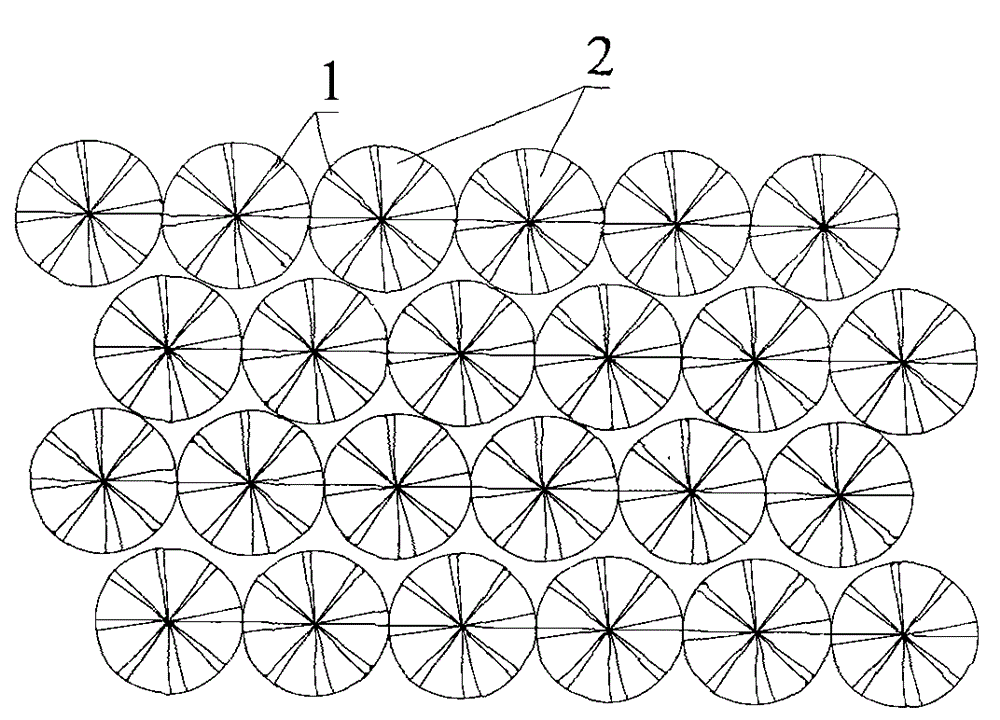

[0061] The fibers made in Examples 1 to 5 are made into non-woven fabrics through opening, carding, and acupuncture. During the preparation of non-woven fabrics, no fiber opening phenomenon occurs in advance. The process requirements and performance of non-woven fabrics are as follows: Table 3 is QB / T2888-2007.

[0062] Table 1, mechanical properties of the composite fiber prepared by the embodiment of the present invention

[0063]

[0064] Table 2 embodiment 2 to ~ embodiment 5 technological parameters

[0065]

[0066] Table 3, the non-woven fabric mechanical property that the embodiment of the present invention prepares

[0067]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| cyclic voltammetry | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com