Method for removing sulfur from fuel before sintering iron ores

A technology of iron ore and fuel, which is applied in the field of interdisciplinary research, can solve the problems of huge amount of SO2, short gas-liquid phase reaction time, and low desulfurization efficiency, and achieve broad development and utilization prospects, long contact time, and high desulfurization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

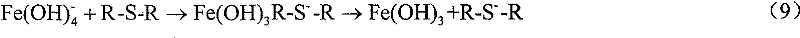

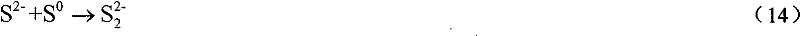

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: 10kg of coke particles (about 5mm) and 5kg of iron ore particles (about 0.5mm) were mixed, and 50kg of water were added to the turbine agitator, 1kg of NaOH was added, and the stirring was continued for 3 hours. The removal rate of sulfur >90%.

Embodiment 2

[0034] Example 2: After the first desulfurization, the obtained liquid was separated and continued to be used to process a mixture of 10kg of coke particles (about 5mm) and 2kg of iron ore particles (about 0.5mm), and mixed with 0.2kg of NaCO 3, continuously stirred for 2 hours in a turbine agitator, and the removal rate of sulfur was >90%.

Embodiment 3

[0035] Example 3: Mix 5kg of anthracite particles (about 5mm) and 2.5kg of iron ore particles (about 0.5mm), add them to the turbine mixer together with 20kg of water, and add 0.5kg of NaCO 3 , continuously stirred for 4 hours, and the removal rate of sulfur was >90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com