Urethane acrylate grouting material capable of repeatedly re-expanding when meeting water and preparation method thereof

A technology of polyurethane acrylate and grouting material is applied in the field of chemical grouting for plugging and waterproofing, which can solve the problems of poor strength and environmental adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

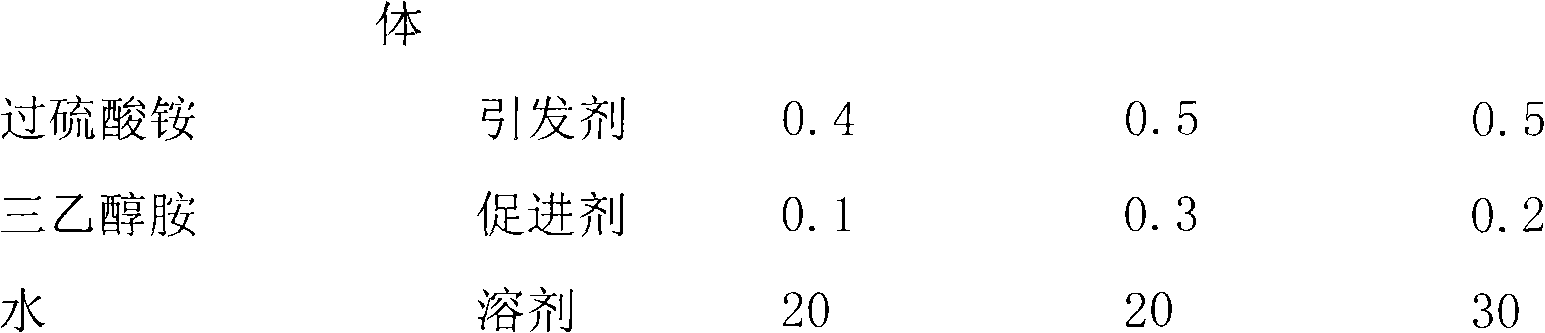

Examples

Embodiment 1

[0045] Preparation of Polyurethane Prepolymer

[0046] Add 100 parts of hydrophilic active polyether polyols into a four-necked flask equipped with a thermometer and a stirrer, dehydrate at a temperature of 120°C and a pressure of -0.098MPa for 2 to 3 hours until no bubbles come out, and then cool down to 50°C, nitrogen protection, add 2 drops of dibutyltin dilaurate and 4 drops of tartaric acid, stir evenly, add 27 parts of TDI dropwise, dropwise for 20 minutes, and keep at this temperature for 30 minutes, then raise the temperature to 80°C, keep About 3 hours, use the dibutylamine method to measure the isocyanate content, stop the reaction when it reaches the theoretical content, cool down to 45°C, add 15 parts of acetone to reduce the viscosity, stir evenly, discharge, and seal the package.

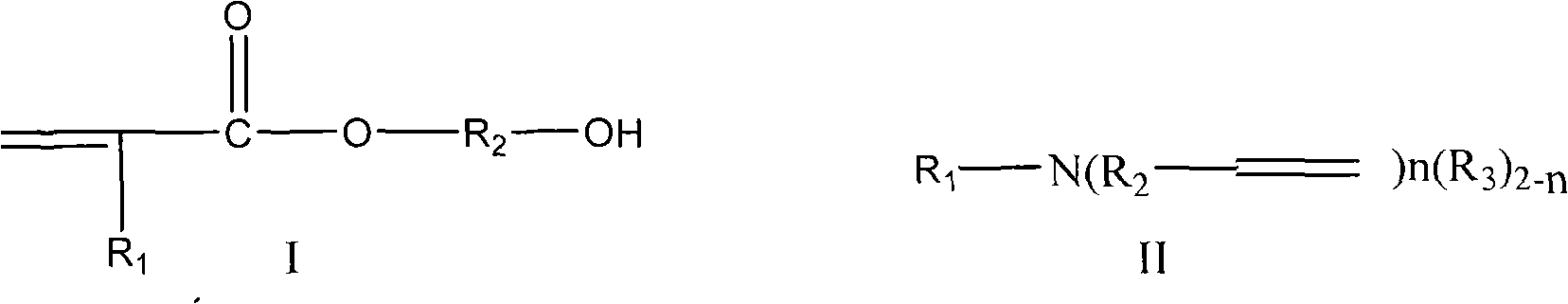

[0047] Preparation of polyurethane acrylate

[0048] Add 100 parts of the above-prepared polyurethane prepolymer into a four-necked flask equipped with a thermometer and a stirrer, ra...

Embodiment 3

[0054] Preparation of Polyurethane Prepolymer

[0055] Add 80 parts of hydrophilic active polyether polyols, 10 parts of polyethylene glycol 1000, and 10 parts of N330 into a four-necked flask equipped with a thermometer and a stirrer at a temperature of 120 °C and a pressure of -0.098 MPa for 2 to 3 Hours, until no bubbles come out, cool down to 50°C, pass through nitrogen protection, stir evenly, add 33 parts of TDI dropwise, finish adding dropwise in 20 minutes, and keep at this temperature for 30 minutes, then raise the temperature to 80°C, keep for about 3 hours , use the dibutylamine method to measure the isocyanate content, stop the reaction when it reaches the theoretical content, cool down to 45°C, stir evenly, discharge the material, and seal the package.

[0056] Preparation of polyurethane acrylate

[0057] Add 100 parts of the above-prepared polyurethane prepolymer into a four-necked flask equipped with a thermometer and a stirrer, heat up to 50°C, add a small am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com