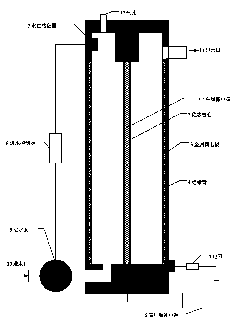

Large liquid phase high pressure pulse discharging water processor

A high-voltage pulse discharge, water processor technology, applied in the fields of magnetic field/electric field water/sewage treatment, etc., can solve the problems of high electrode processing cost, low mechanical strength, difficult reactor, etc., to reduce the cost of power equipment, processing and manufacturing The effect of easy, increased processing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The coaxial electrode structure is composed of a metal rod with a diameter greater than 3mm and a metal cylinder with a diameter greater than 45mm, and the distance between the central metal rod and the metal cylinder is greater than 20mm. The central metal rod electrode is covered with a layer of insulating tube with micro-slits with a width of 20-100 microns. The metal cylinder is covered with an insulating tube and grounded through a resistor. The water to be treated is sent into the reactor through the water inlet pump, and the water level is sensed by the water level sensor to control the water inlet. Apply a pulse high voltage of more than 20kV to the central metal rod electrode, and a local high electric field will be generated at the fine crack of the insulating tube on the central metal rod electrode to cause discharge, thereby generating discharge plasma in the water to be treated in the cylinder. According to actual needs, the water outlet of the above-menti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com