Method for desulphurizing cassiterite polymetallic sulphide ore tailing by flotation step by step

A technology for sulfide ores and polymetals, applied in flotation, solid separation, etc., can solve the problems of many types of chemicals, affecting the sorting effect, easy to form sludge, etc., to reduce the type and quantity of chemicals, avoid inadvertent loss, reduce The effect of cassiterite inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

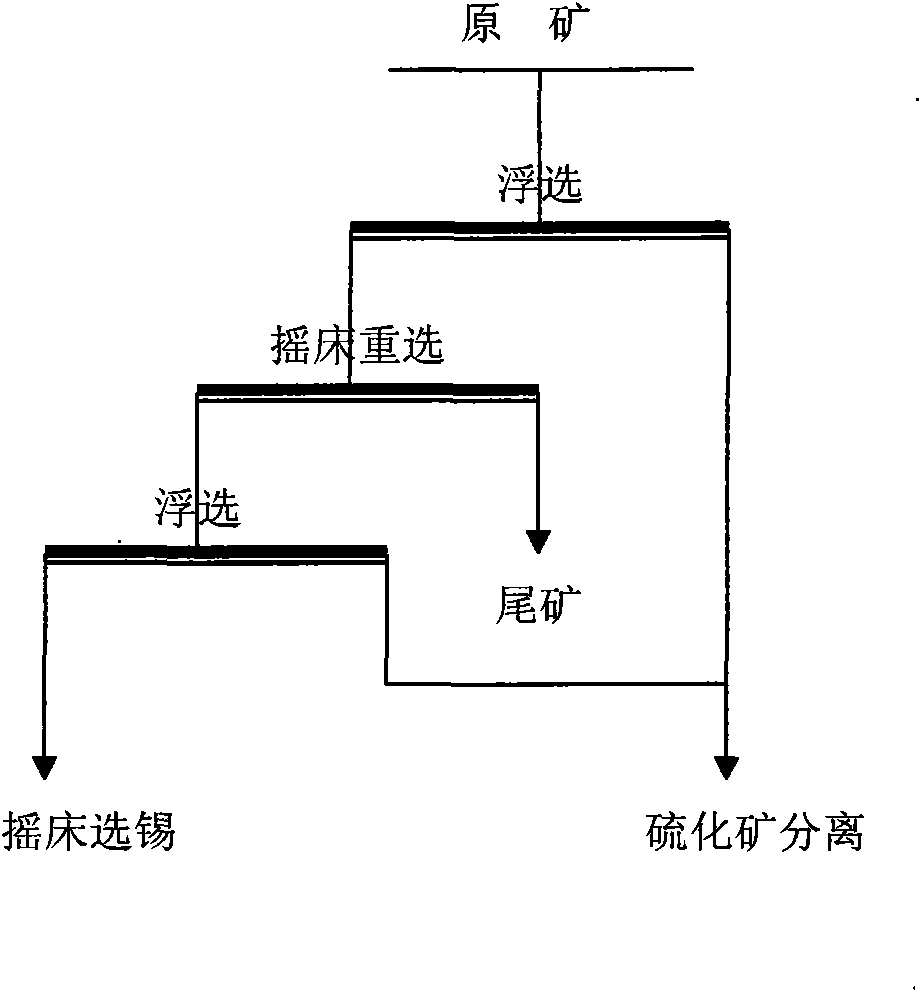

Image

Examples

Embodiment 1

[0021] Mineral raw materials:

[0022] The raw materials used are tailings containing low-grade cassiterite and sulfide ores, which contain Sn0.54%, Pb0.47%, Zn2.10%, and Sb0.38%. The recovered minerals in the tailings are mainly cassiterite and brittle sulfur Antimonite, sphalerite, etc.

[0023] The above mineral raw materials are desulfurized and flotation step by step according to the following steps:

[0024] 1.1 Flotate the sulfide ore with good floatability first, the pH value of the pulp is 7 during flotation, and then add butyl xanthate and 2 # The oil is used to recover sulfide ores with good buoyancy, dosage: butyl xanthate 200g / t, 2 # Oil 80g / t, butyl xanthate first prepared into 1wt% aqueous solution, 2 # The oil is added directly to the stock solution.

[0025] The mixed concentrate of sulfide ore containing Sn0.20%, Pb2.67%, Sb2.33%, Zn16.04% was obtained by flotation, and the recoveries of tin, lead, antimony and zinc were respectively Sn9.57%, Pb59.25 %, ...

Embodiment 2

[0035] Mineral raw materials:

[0036] The raw materials used are tailings containing low-grade cassiterite and sulfide ores, which contain Sn0.60%, Pb0.50%, Zn2.35%, and Sb0.45%. The recovered minerals in the tailings are mainly cassiterite and brittle sulfur Antimonite, sphalerite, etc.

[0037] The above mineral raw materials are desulfurized and flotation step by step according to the following steps:

[0038] 1.1 Flotate the sulfide ore with good floatability first, the pH value of the pulp is 7 during flotation, and then add butyl xanthate and 2 # The oil is used to recover sulfide ores with good buoyancy, dosage: butyl xanthate 300g / t, 2 # Oil 100g / t.

[0039] Butyl xanthate is first prepared into 2wt% aqueous solution, 2 # The oil is added directly to the stock solution.

[0040] Flotation obtained sulfide ore mixed concentrate containing Sn0.20%, Pb2.87%, Sb2.56%, Zn16.53%, the recoveries of tin, lead, antimony and zinc were Sn9.67%, Pb61.03 %, Sb61.52%, Zn65.67...

Embodiment 3

[0050] Mineral raw materials:

[0051] The raw materials used are tailings containing low-grade cassiterite and sulfide ores, which contain Sn0.57%, Pb0.48%, Zn2.21%, Sb0.41%. The recovered minerals in the tailings are mainly cassiterite and brittle sulfur Antimonite, sphalerite, etc.

[0052] The above mineral raw materials are desulfurized and flotation step by step according to the following steps:

[0053] 1.1 Flotate the sulfide ore with good floatability first, the pH value of the pulp is 7 during flotation, and then add butyl xanthate and 2 # The oil is used to recover sulfide ores with good buoyancy, dosage: butyl xanthate 250g / t, 2 # Oil 90g / t, butyl xanthate first prepared into 1wt% aqueous solution, 2 # The oil is added directly to the stock solution.

[0054] The mixed concentrate of sulfide ore containing Sn0.20%, Pb2.75%, Sb2.51%, and Zn16.37% was obtained by flotation, and the recoveries of tin, lead, antimony, and zinc were respectively Sn9.61%, Pb60.17 %,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com