Method for starting three-phase modular multilevel inverter without auxiliary DC power supply

A multi-level converter and three-phase module technology, applied in the direction of output power conversion device, AC power input conversion to DC power output, electrical components, etc., can solve the problem of increasing equipment investment, restrictions, and inability to meet engineering needs, etc. problem, achieve the effect of reducing system complexity, shortening charging time, and increasing charging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

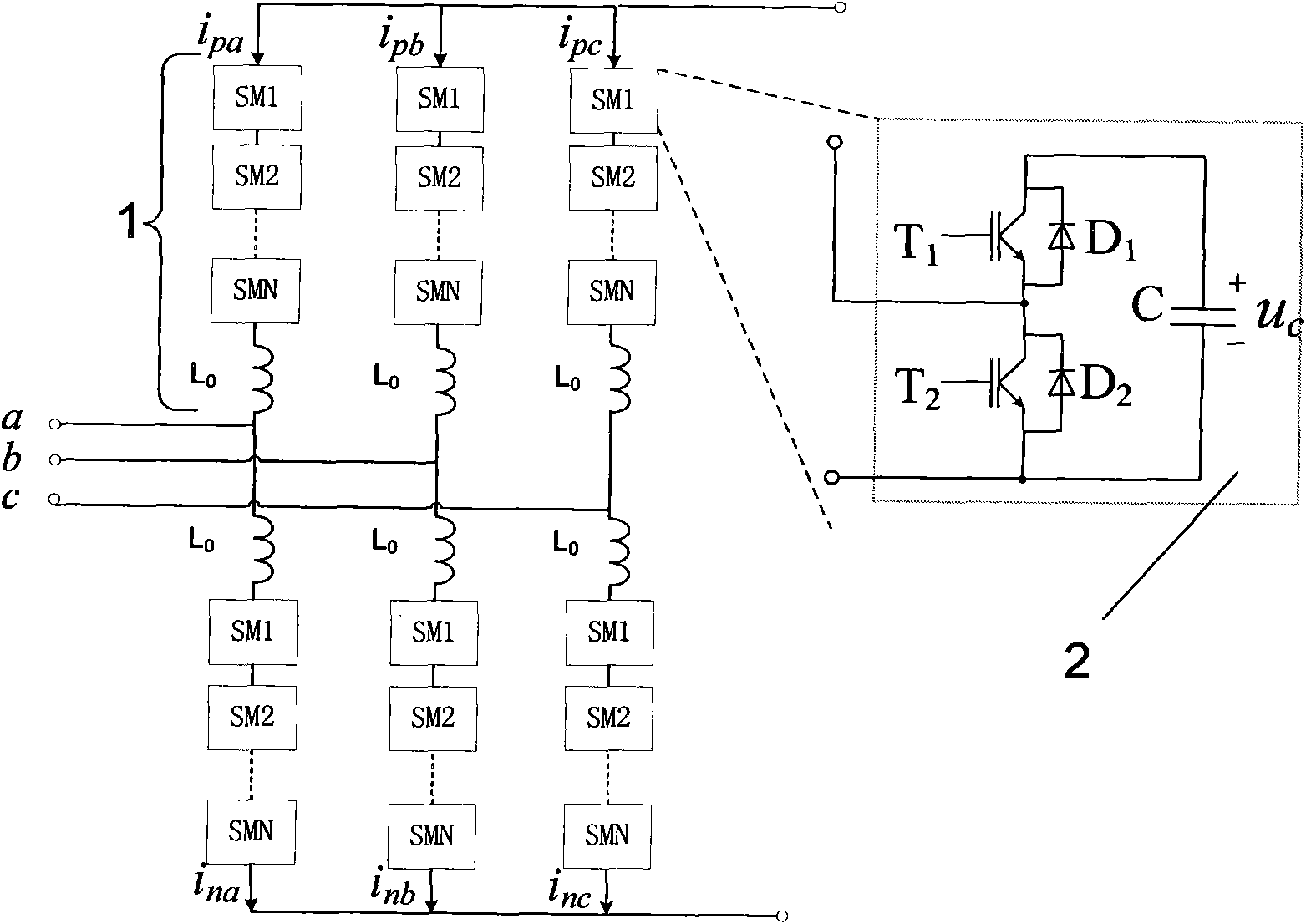

[0023] Such as figure 1 As shown, the three-phase modular multilevel converter is composed of six bridge arms in three phases a, b, and c, and each phase has two upper and lower bridge arms. Each bridge arm 1 consists of a reactor L 0 It is formed by cascading with N submodules 2. The sub-modules SM1~SMN have the same structure, and each sub-module is composed of the first power electronic switch T 1 , the second power electronic switch T 2 (T 1 , T 2 Select a power electronic switch with self-shutoff capability, usually IGBT, IGCT, GTO, etc., the present invention uses IGBT), a diode D connected in antiparallel with the first power electronic switch 1 , a diode D connected in antiparallel with the second power electronic switch 2 and DC capacitor C. Among them, the capacitor C and the first power electronic switch T 1 After being connected in series, it is connected with the second power electronic switch T 2 in parallel. The voltage across the capacitor C is u c ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com