Testing machine for testing performance of reverse gear assembly

A shifter and testing machine technology, which is applied in the direction of machine gear/transmission mechanism testing, etc., can solve problems such as inaccurate data, test failure, difficult shifting levers, etc., and achieve the benefits of testing, accurate and controllable rotation range, and automation high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described below with reference to the drawings.

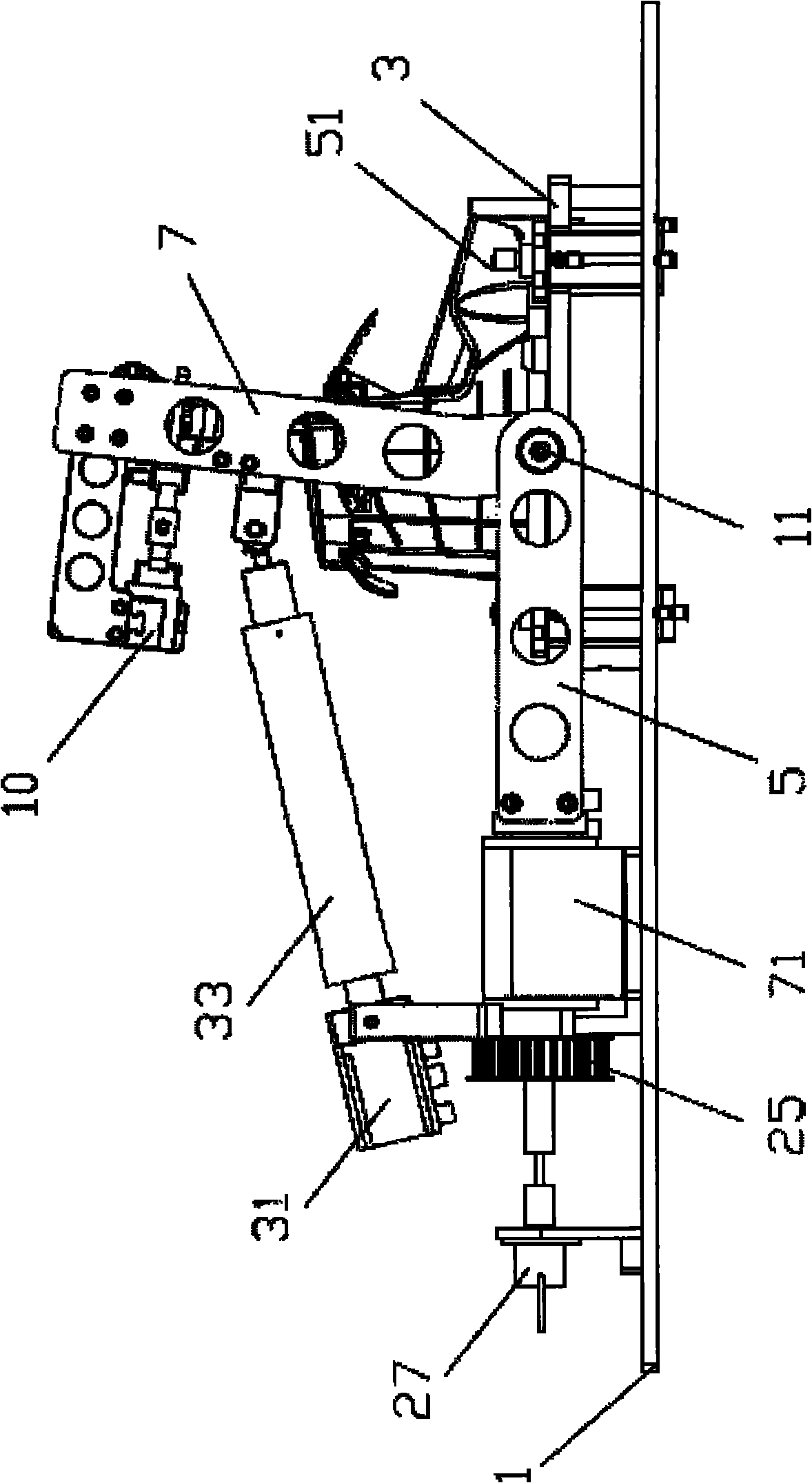

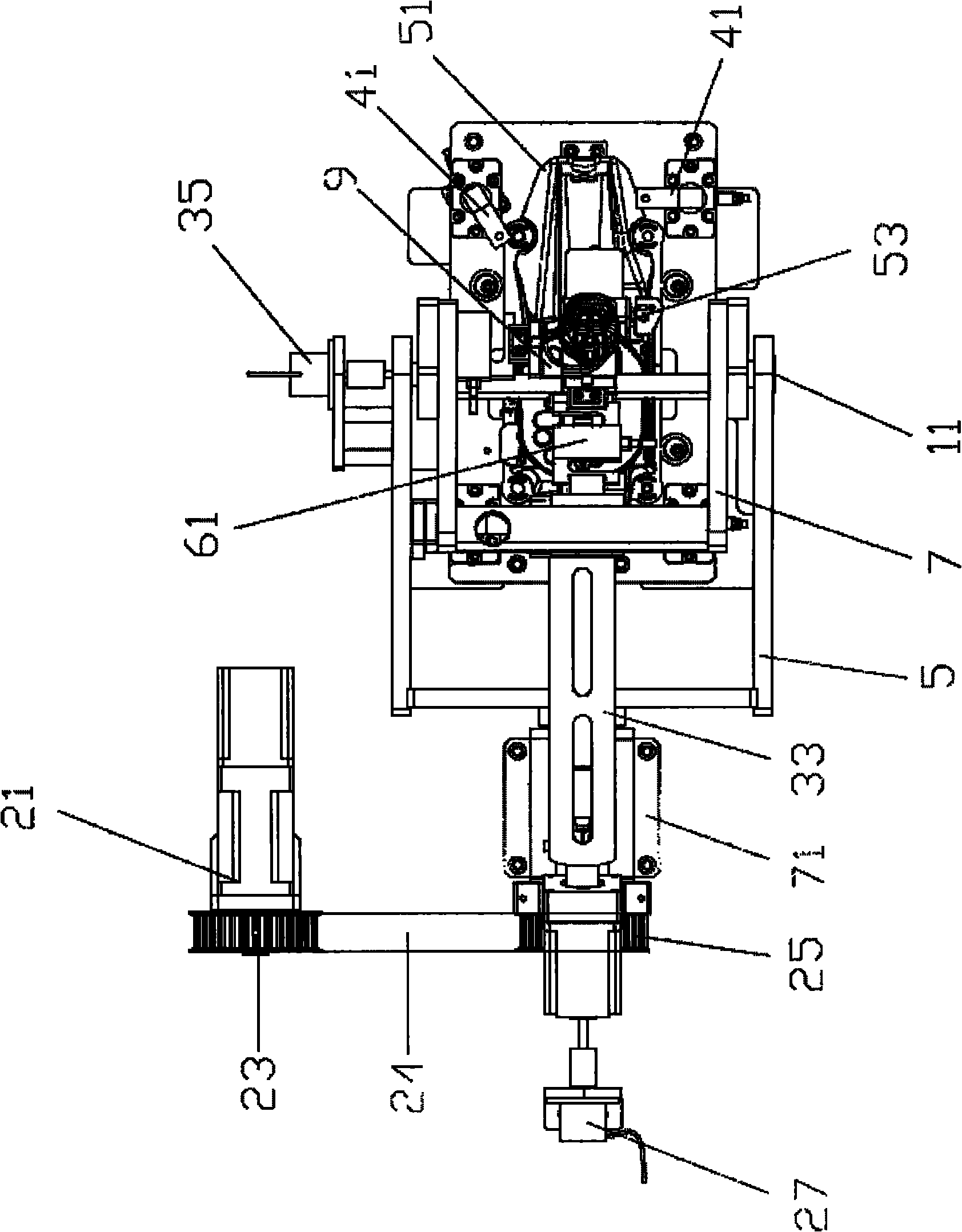

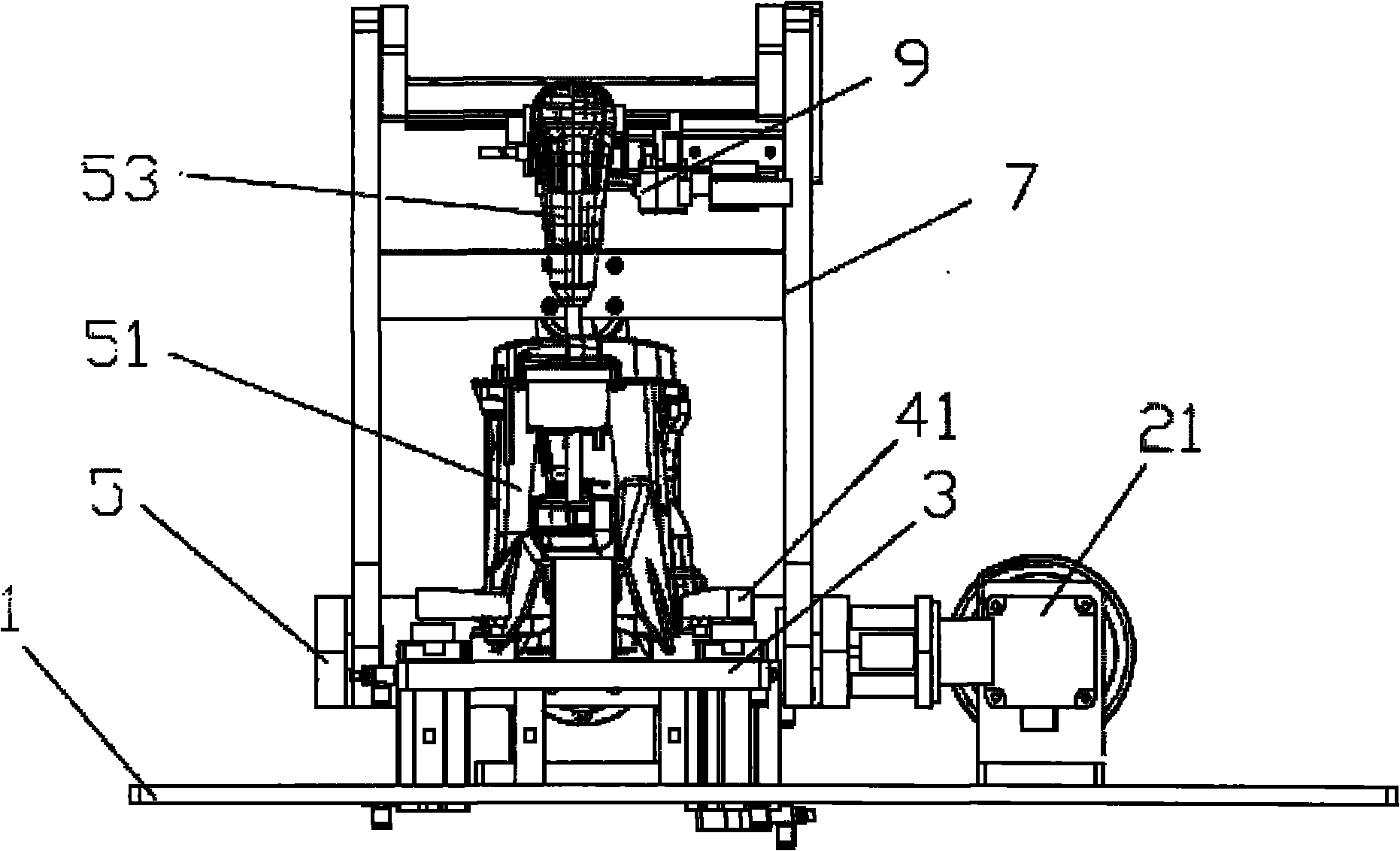

[0028] Such as figure 1 , the base 3 of the shifter assembly performance test test machine is installed on the workbench 1, and the base 3 is used to fix the shifter seat 51 of the shifter assembly, wherein the shifter assembly also includes a shift lever 53. The positioning connection method of the shifter base 51 is to set a number of positioning pins on the machine base 3, and set a number of positioning holes matching the number, position and shape on the shifter base 51, and connect the positioning pins and positioning holes together. After a corresponding assembly, the shifter base 51 can be positioned on the machine base 3 . The base 3 is also provided with several pneumatic clamping parts 41. After the shifter seat 51 is positioned, the pneumatic switch can be turned on to drive the pneumatic clamping parts 41 to fix the shifter base 51 on the base 3 on.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com