Elevating lever-type stop valve

A technology of stop valve and lifting rod, which is applied in the field of lifting rod type stop valve, can solve the problems of large opening and closing, reduced sealing performance, poor adjustment performance, etc., and achieves small opening and closing force, few components and good adjustment performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

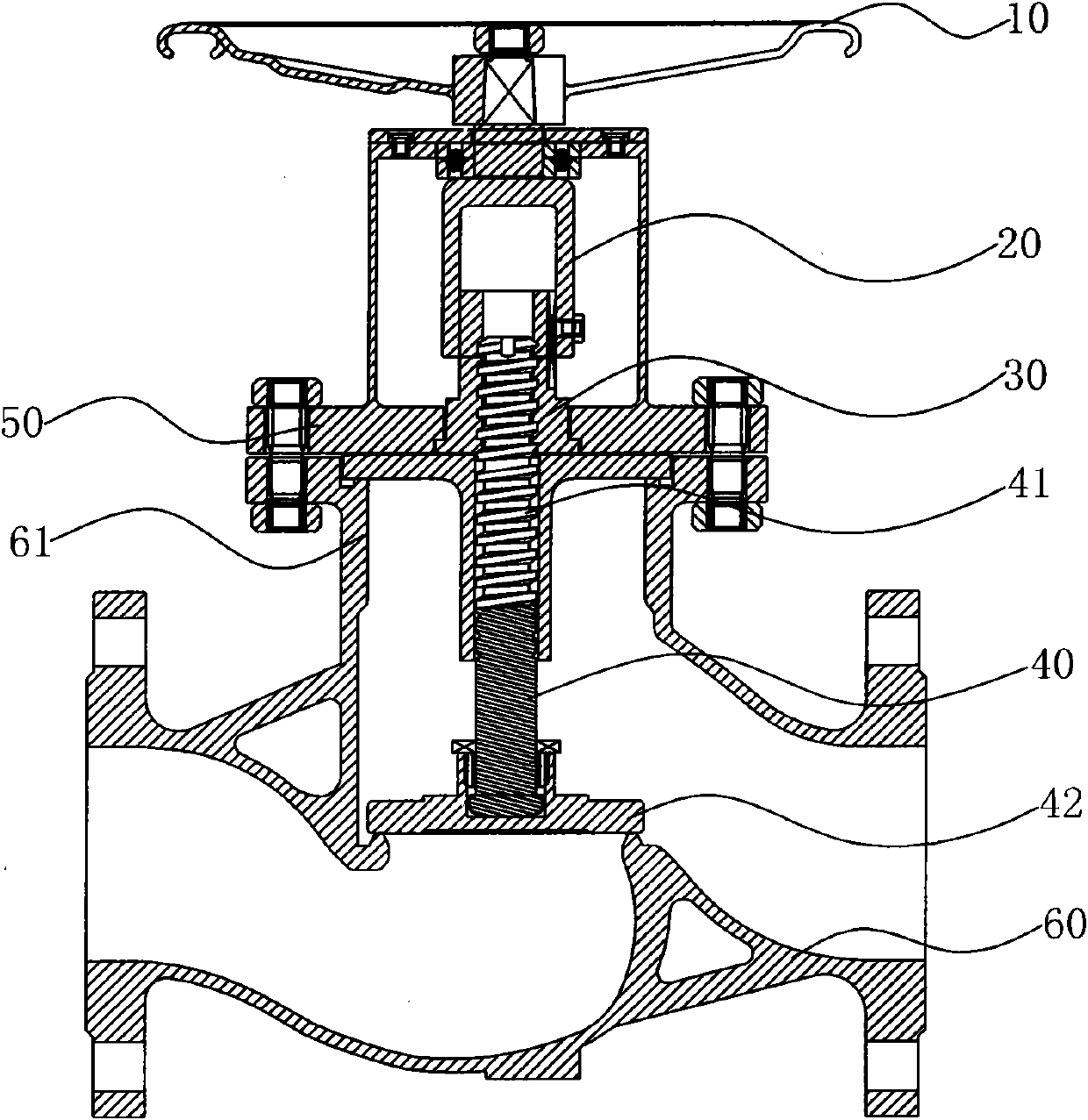

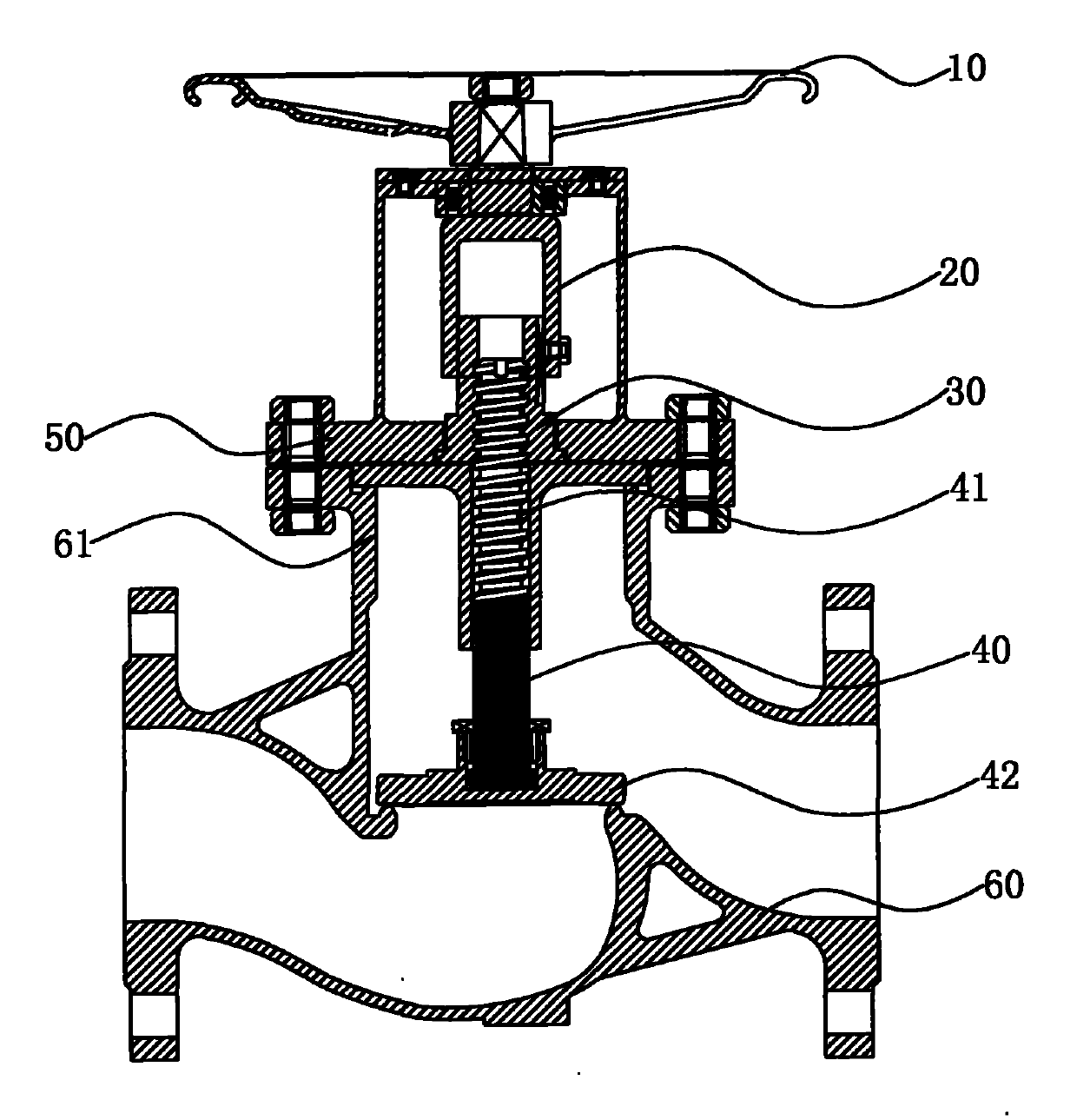

[0016] Such as figure 1 As shown, the lifting rod type globe valve has a valve seat 60 and a valve disc 42, and the valve disc is assembled on the lower end of the valve shaft 40 through a threaded connection. The valve shaft 40 is set in cooperation with a cap nut 30 through the driving thread 41, and the cap nut 30 is limited on a valve cap 50, and the cap nut 30 is driven by the handwheel driving handle 20, and the rotation of the cap nut 30 drives the valve through the driving thread 41. The shaft 40 moves up and down to realize the opening and closing of the fluid channel in the valve seat 60 . A hole frame 61 is arranged on the upper part of the valve seat 60, and a valve cover 50 is used for flange sealing outside the hole frame mouth. The opening of the chassis is embedded, and the cover nut 30 is limitedly installed in the opening of the valve cover. A shaft sleeve is also installed in the hole frame, and the upper part of the shaft sleeve has a top cover, and the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com