Anhydrous indium chloride synthesizing method

A synthesis method and technology of indium chloride, applied in chemical instruments and methods, inorganic chemistry, chloride preparation, etc., can solve the problems of low yield, low product purity, serious pollution, etc., and achieve high yield and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

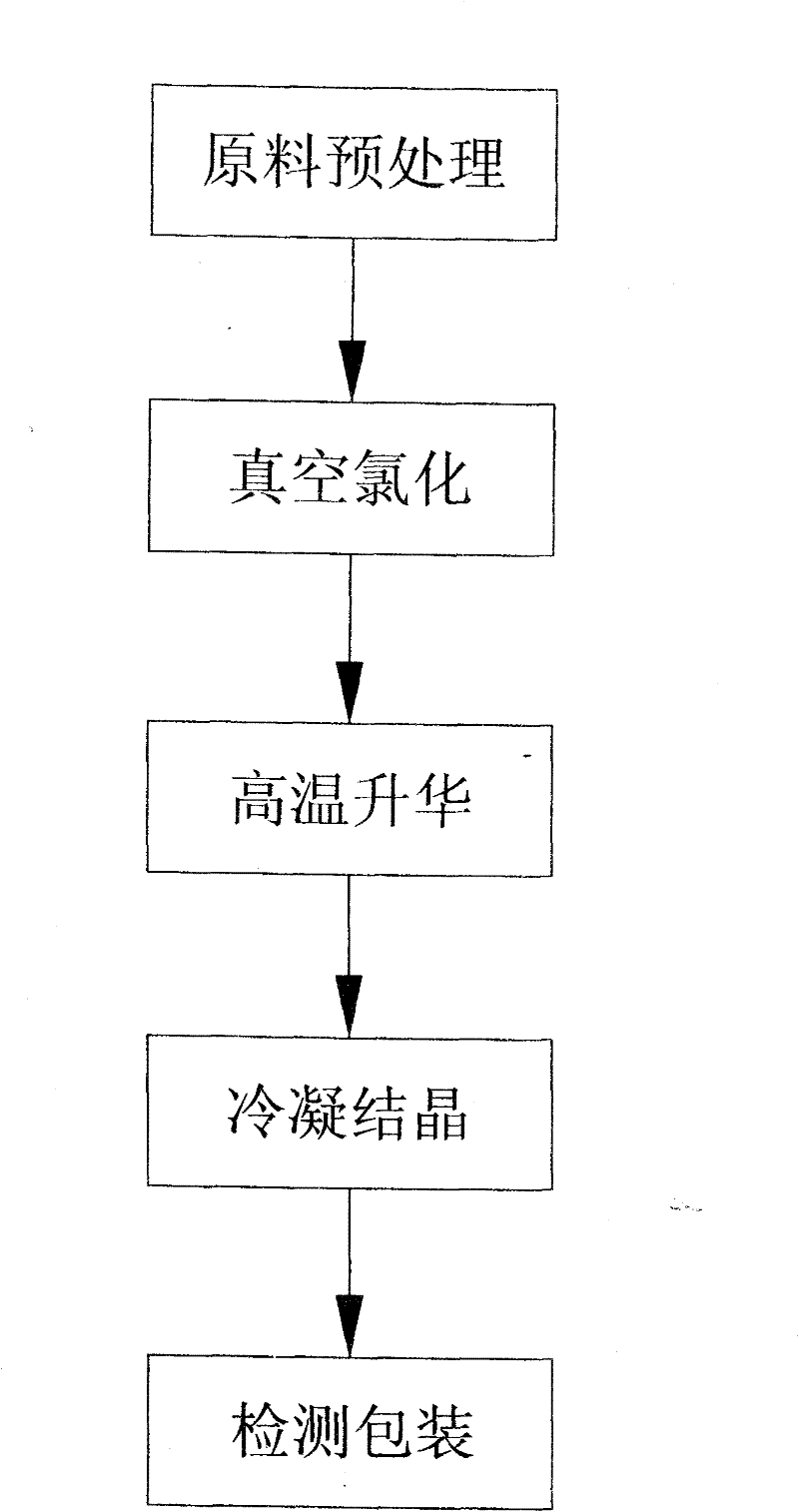

[0012] Below in conjunction with accompanying drawing and embodiment the present invention is further described: see figure 1 , a kind of anhydrous indium chloride synthesis method, its processing step is:

[0013] One is pretreatment: take 25 kg of 5N high-purity metal indium, put it in a vacuum quartz furnace, put it in a quartz container coated with graphite composite material, and then vacuumize it. After the negative pressure is stable, gradually increase the temperature to 700- 1200°C, keep the temperature and negative pressure conditions unchanged for one hour, after the pretreatment, close the vacuum valve, pass high-purity argon after cooling, and take out the metal indium from the vacuum operating room under the protection of argon and seal it for storage.

[0014] The second is vacuum chlorination: 25 kg of pretreated high-purity indium ingots are put into the vacuum reaction furnace, packed in a quartz container coated with graphite composite material, vacuumized a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com