Mold used for manufacturing fan blade shearing ribs of wind generating set

A technology for wind turbines and molds, which can be applied to home appliances, other home appliances, applications, etc. It can solve the problems of increased equipment maintenance costs, high maintenance costs, and difficult correction of deformation, so as to achieve low maintenance costs and low production costs. Low and easy deformation correction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] At present, the shear rib mold is made of glass fiber reinforced plastics, which not only makes the mold manufacturing process complicated, but also uses a variety of materials, and the production cost is high. Moreover, the maintenance cost of this kind of mold is relatively high, and it is difficult to correct the deformation after long-term use, which increases the equipment. maintenance costs.

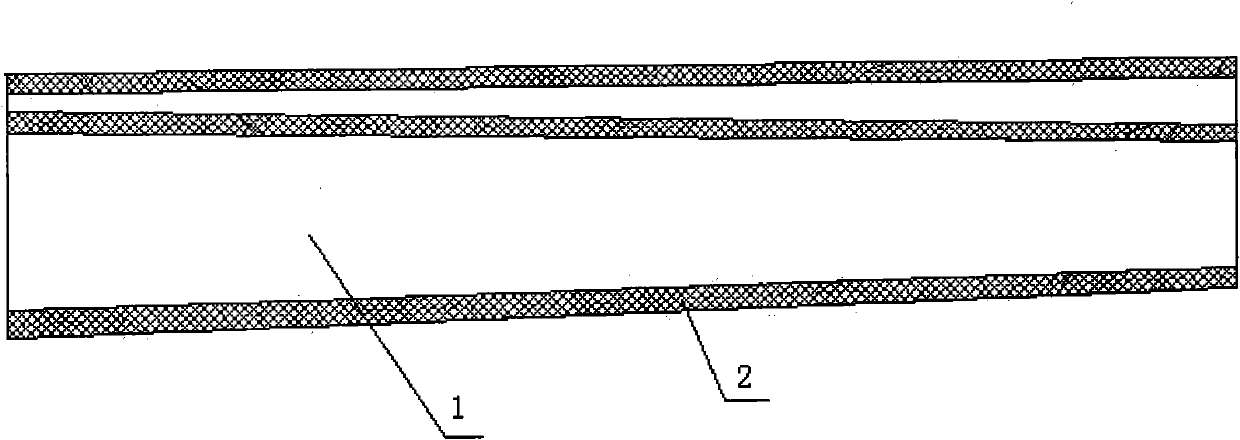

[0010] figure 1 It is a structural schematic diagram of the mold of the present invention. The mold for manufacturing the blade shear rib of the wind power generating set of the present invention includes a mold cavity 1 and a flanging 2, and the mold material is steel. The use of steel molds makes the mold manufacturing process simple, the material types are single, the production cost is low, and the later maintenance cost is low, and deformation correction is easy.

[0011] The above has disclosed the present invention with preferred embodiments, but it is not intended ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com