Method and equipment for preparing green tiles of ceramic tiles

A kind of adobe and ceramic technology, which is applied in the field of adobe preparation of ceramic thin bricks, can solve the problems of increasing the structural complexity of hydraulic presses, reducing the yield, and short service life, so as to improve equipment utilization, avoid short service life, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

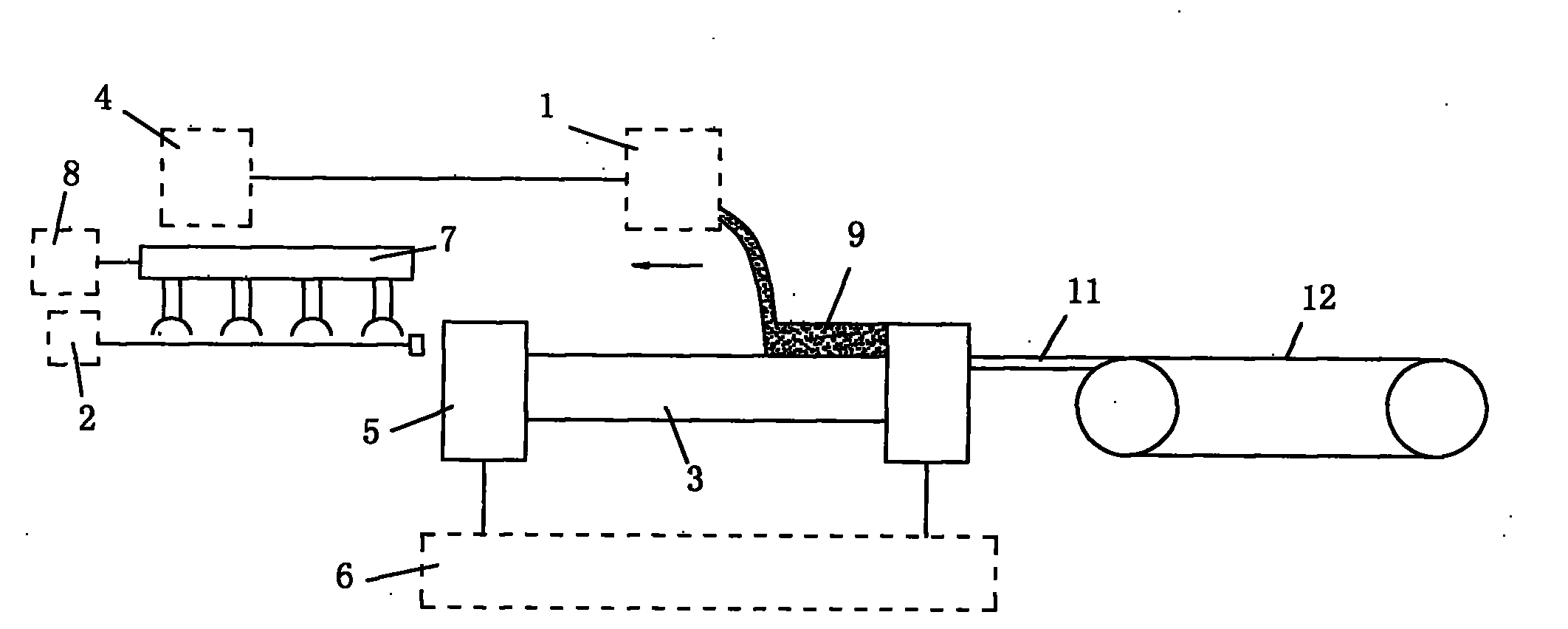

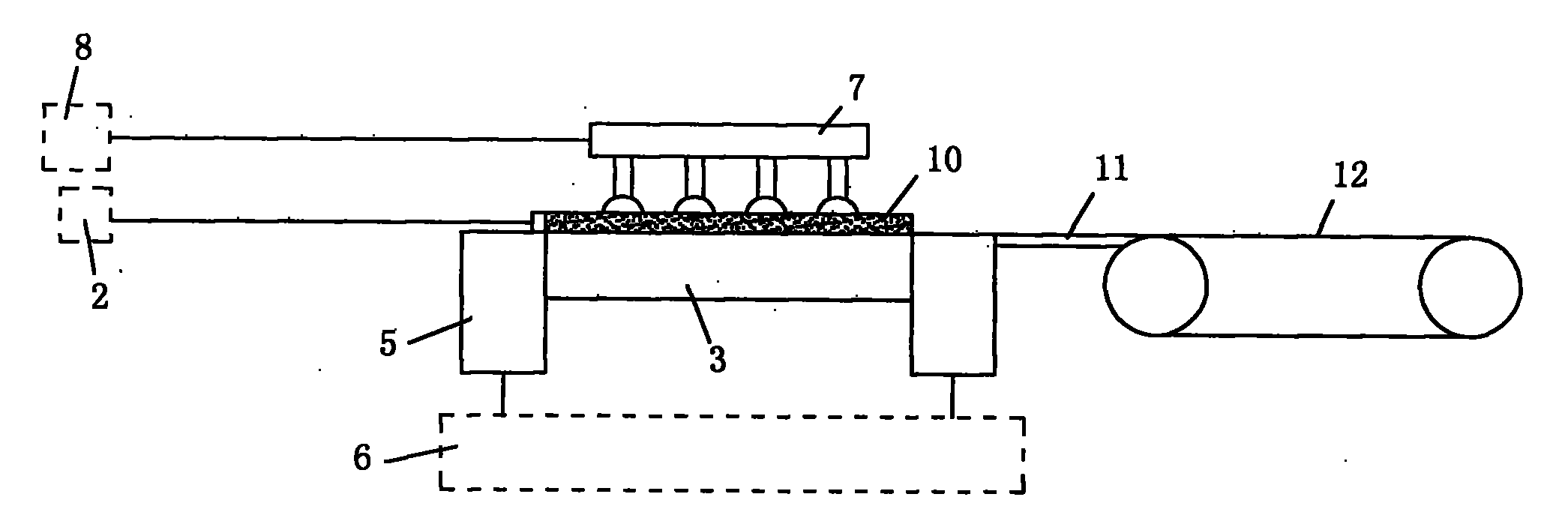

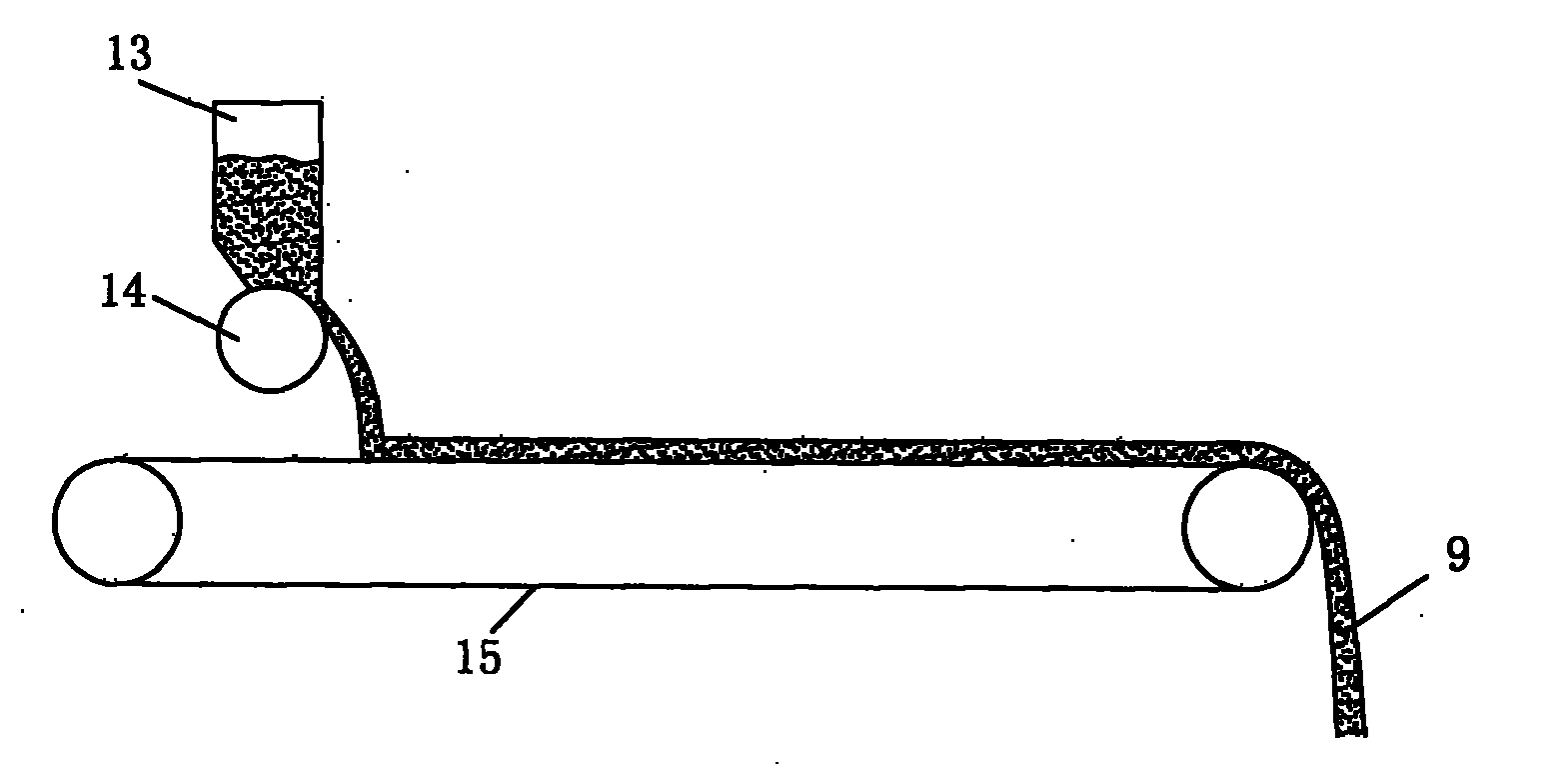

[0021] figure 1 The adobe preparation equipment shown includes a powder material output device 1 that sprinkles powder with a uniform flow rate (only a dotted line box is used to summarize the figure), and a transfer device 2 that moves the brick adobe horizontally (only a dotted line box is used in the figure to summarize) express). figure 1 The hydraulic press for pressing the ceramic powder in the mold into adobe is omitted. The feature of the adobe preparation equipment is that the output end of the powder material output device 1 is located above the mold core 3 of the adobe forming mold, and the powder material output device 1 is connected with a translation mechanism 4, and the translation mechanism 4 drives the powder material output device 1. The output end moves, and the direction of movement is parallel to the working surface of the mold core 3; it also includes an adsorption device 7 that absorbs brick adobe upwards, and the adsorption device 7 is connected with a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap