Milled screen stencil structure with conical filtering surface for pusher centrifuge and method for machining same

A pusher centrifuge, conical technology, applied in the direction of centrifuges, etc., can solve the problems of hindering pusher, bolt breakage, affecting the normal operation of the machine, etc., and achieve the effect of reducing resistance, reducing wear and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

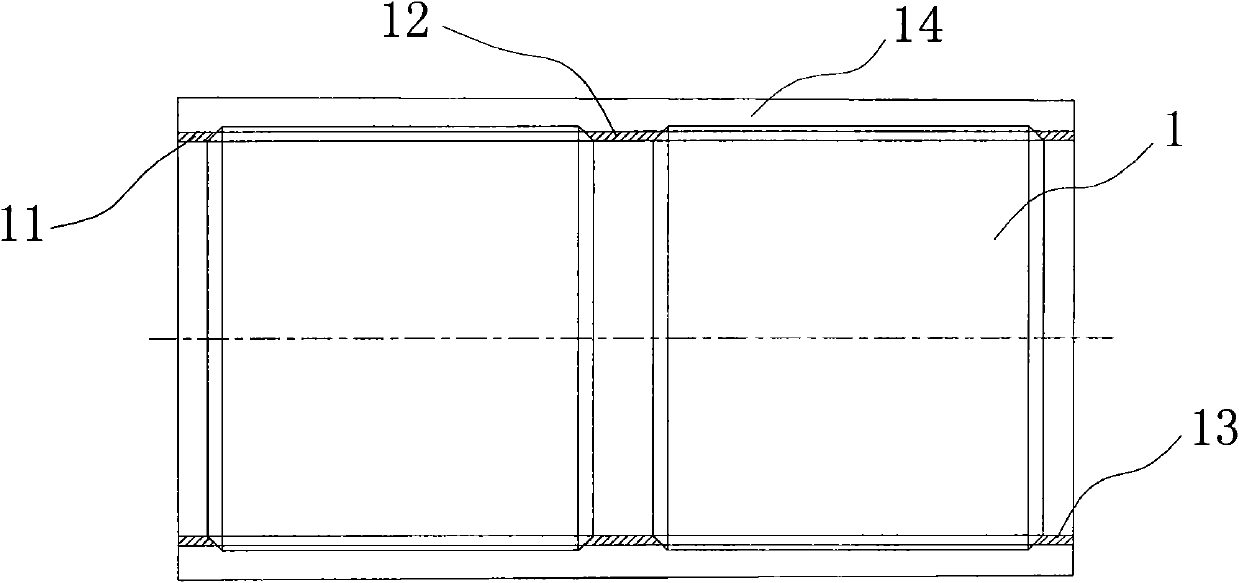

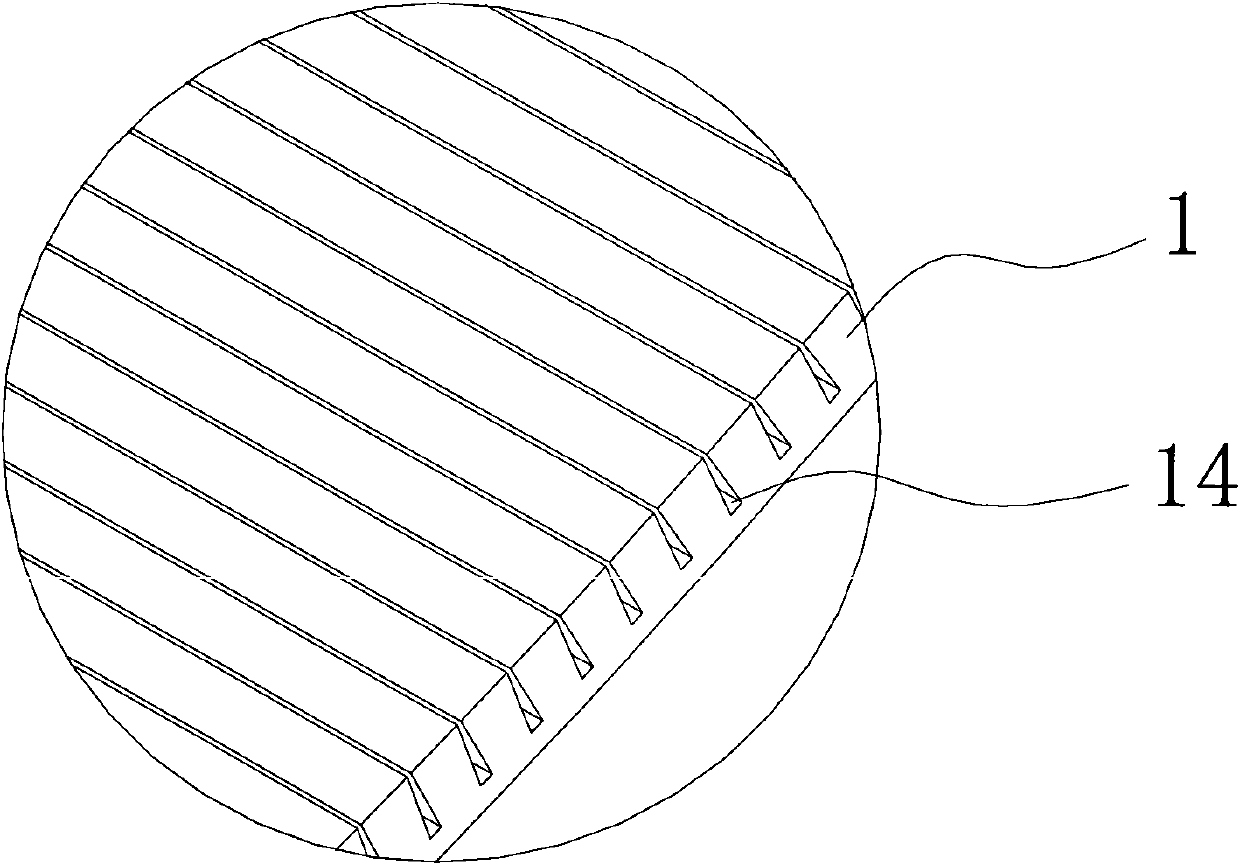

[0026] see figure 1 In this embodiment, the milling screen structure of a conical filter surface of a pusher centrifuge is that the milling screen is a cylinder 1 with a conical inner hole, and the entire circumference of the cylinder 1 wall is provided with mutual Parallel through grooves 14, all the through grooves 14 penetrate the cylinder wall of the cylinder body 1, the cross section of the through grooves 14 is trapezoidal, the short top edge of the trapezoid is towards the center of the inner hole of the cylinder body 1, the two ends of the cylinder body 1 and Connectors are provided in the middle.

[0027] The processing method of the milling screen mesh structure of the conical filter surface of this pusher centrifuge is that on the blank wall of a cylinder 1 with a conical inner hole, the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com