Modified sludge activated carbon used for low-concentration flue gas desulfurization and denitration and preparation method thereof

A technology of sludge activated carbon and low concentration, which is applied in the field of activated carbon and can solve the problems of poor adsorption and desulfurization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

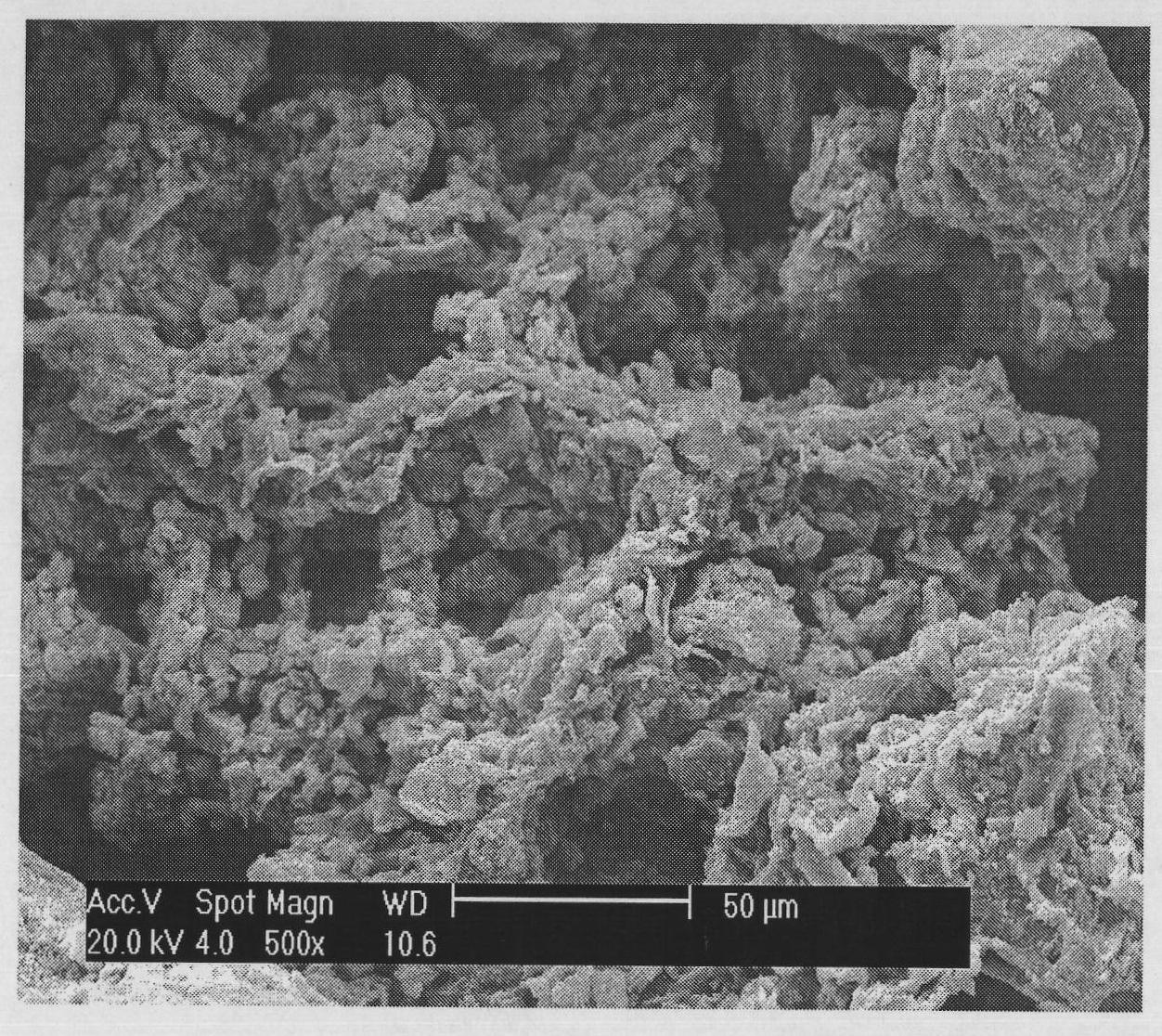

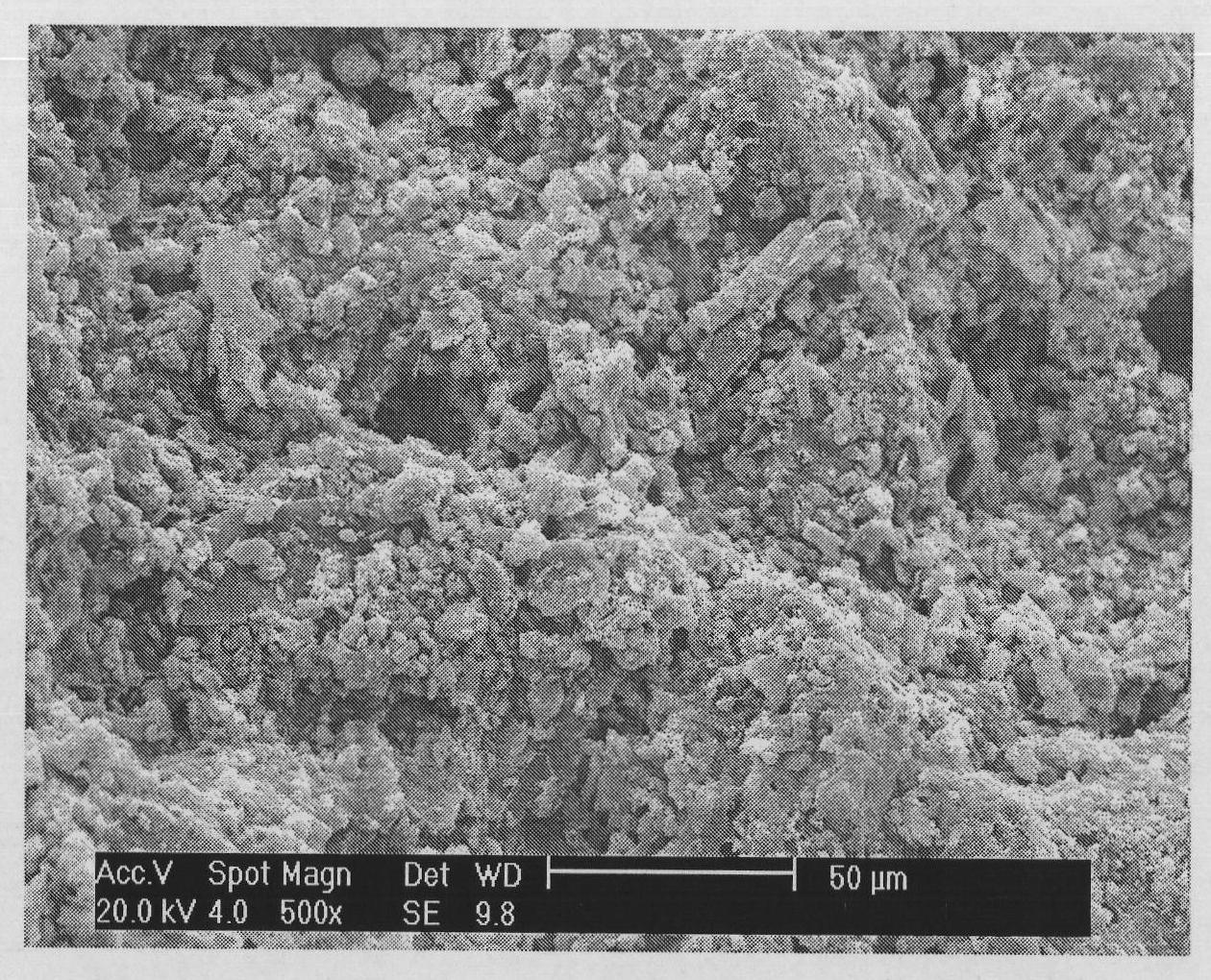

Image

Examples

Embodiment 1

[0026] ① Preparation of chitosan solution

[0027] Dissolve 0.20g of chitosan in 15mL of acetic acid solution (1vol%), then add 10mL of distilled water, and then ultrasonically disperse for 3h to make a 2.5wt% uniform solution;

[0028] ②Preparation of sludge activated carbon

[0029] Put the dried sludge into a carbonization furnace, carbonize at 200°C, use nitrogen to isolate the air, the nitrogen flow rate is 50L / h, the heating rate is controlled at 5°C / min, and carbonized for 4h to obtain carbonized material. Then the prepared carbonized material was activated at 1000°C, using steam with a flow rate of 100L / h, the heating rate was controlled at 15°C / min, and activated for 0.5h to obtain sludge activated carbon.

[0030] ③ Preparation of chitosan-modified sludge activated carbon for simultaneous desulfurization and denitrification of flue gas

[0031] Immerse 10g of sludge activated carbon into the solution of the above step ①, stir for 1 hour, then take it out, filter it...

Embodiment 2

[0036] ① Preparation of chitosan solution

[0037] Dissolve 0.15g of chitosan in 10mL of acetic acid solution (1vol%), add 5mL of distilled water, and then ultrasonically disperse for 6h to make a 2.0wt% uniform solution;

[0038] ②Preparation of sludge activated carbon

[0039] Put the dry sludge into the carbonization furnace, carbonize at 400°C, use nitrogen to isolate the air, the nitrogen flow rate is 100L / h, the heating rate is controlled at 15°C / min, carbonize for 1h, and the carbonized material is obtained. Then, the prepared carbonized material was activated at 500°C, using steam with a flow rate of 50L / h, the heating rate was controlled at 35°C / min, and activated for 1h to obtain sludge activated carbon.

[0040] ③ Preparation of chitosan-modified sludge activated carbon for simultaneous desulfurization and denitrification of flue gas

[0041] Immerse 5g of sludge activated carbon into the solution of the above step ①, stir for 3 hours, then take it out, filter it ...

Embodiment 3

[0045] ① Preparation of chitosan solution

[0046]Dissolve 0.10g of chitosan in 5mL of acetic acid solution (1vol%), then add 3mL of distilled water, and then ultrasonically disperse for 12h to make a 0.5wt% uniform solution;

[0047] ②Preparation of sludge activated carbon

[0048] Put the dry sludge into the carbonization furnace, carbonize at 800°C, use nitrogen to isolate the air, the nitrogen flow rate is 10L / h, the heating rate is controlled at 35°C / min, and carbonization is carried out for 0.5h to obtain carbonized material. Then the prepared carbonized material was activated at 200°C, using steam with a flow rate of 10L / h, the heating rate was controlled at 5°C / min, and activated for 4h to obtain sludge activated carbon.

[0049] ③ Preparation of chitosan-modified sludge activated carbon for simultaneous desulfurization and denitrification of flue gas

[0050] Immerse 2g of sludge activated carbon into the solution of the above step ①, stir for 5 hours, then take it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com