Polyvinylidene fluoride hollow fiber membrane with base material and production method thereof

A polyvinylidene fluoride, fiber membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of low flux, poor hydrophilicity, complex process, etc., to improve flux and strength , long-term hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

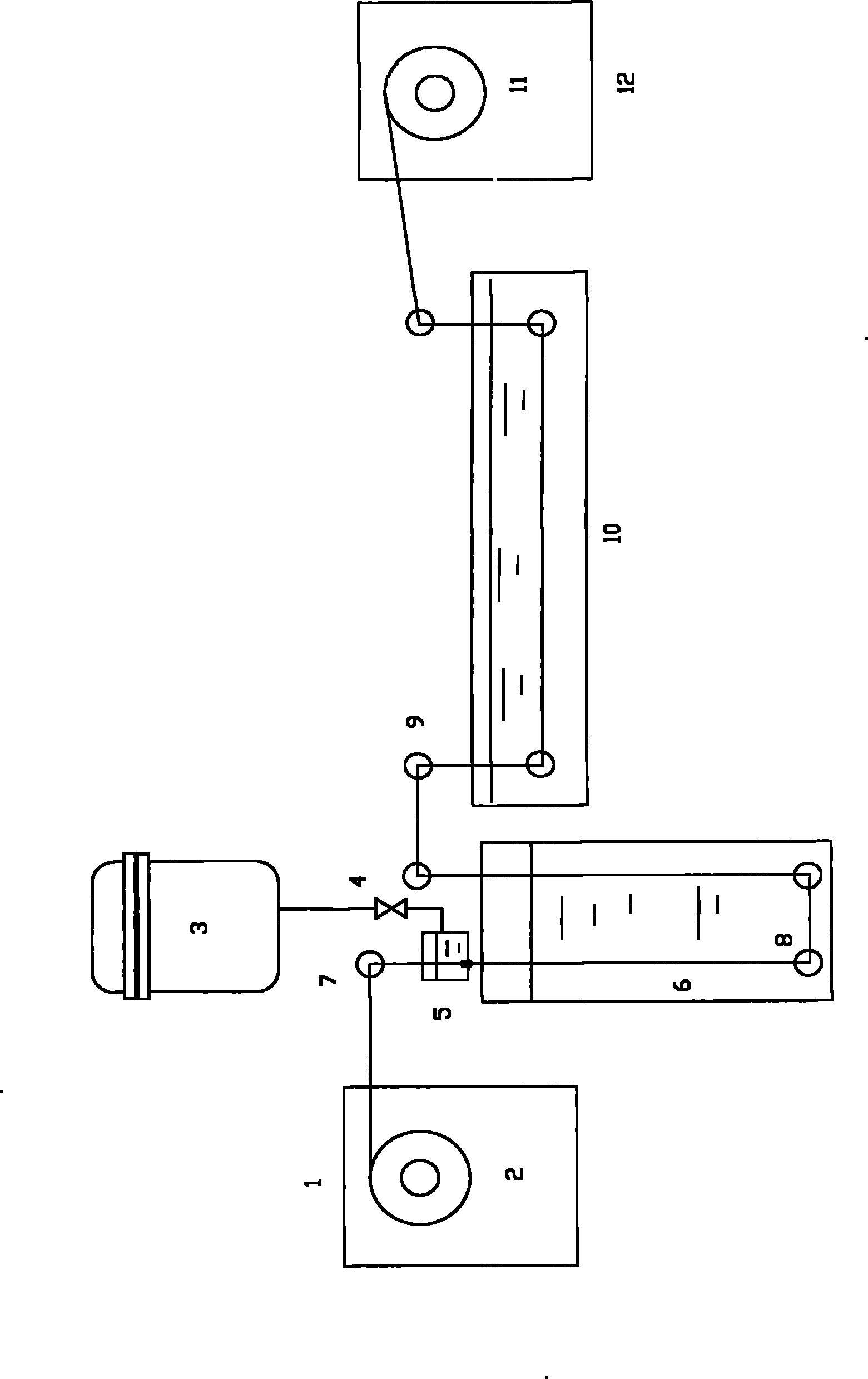

Method used

Image

Examples

Embodiment 1

[0076] First prepare the film-making feed solution:

[0077] Mix polyvinylidene fluoride resin, N-methylpyrrolidone solvent, and polyethylene glycol additives sold by Sanaifu Company under the trade name PVDF in a weight ratio of 15:80:5, stir them evenly with a mechanical mixer, and then use a negative pressure The method is to carry out defoaming, and the film-making feed liquid made after defoaming is placed in the feed liquid tank;

[0078] Next prepare the gel bath:

[0079] N-methylpyrrolidone solvent, water and sodium hypochlorite oxidizing agent are formulated into a mixed liquid according to a weight ratio of 60:35:5, which is used as a gel bath for circulation.

[0080] Then, prepare polyvinylidene fluoride hollow fiber membrane with substrate under the following conditions:

[0081] Place the glass fiber rope on the wire feeder, the outer diameter of the glass fiber is 1.3mm, the inner diameter is 0.9mm, and the wall thickness of the fiber rope is 0.2mm; the windi...

Embodiment 2

[0097] First prepare the film-making feed solution:

[0098] Mix polyvinylidene fluoride resin, dimethylformamide solvent, and polyvinylpyrrolidone additives sold by Solvay under the trade name Solef in a weight ratio of 22:68:10, stir them evenly with a mechanical mixer, and then use a decompression Degassing is carried out by the method, and the film-making feed liquid made after degassing is placed in the feed liquid tank;

[0099] Next prepare the gel bath:

[0100] Dimethylformamide solvent, water, and ammonium persulfate oxidizing agent are formulated into a mixed solution in a weight ratio of 14:85:6, which is used as a gel bath for circulation.

[0101] Then, prepare polyvinylidene fluoride hollow fiber membrane with substrate under the following conditions:

[0102]Put the glass fiber rope on the fiber rope feeding machine, the outer diameter of the glass fiber is 2.0mm, the inner diameter is 1.4mm, the wall thickness of the fiber rope is 0.3mm; the winding speed of...

Embodiment 3

[0118] First prepare the film-making feed solution:

[0119] Mix the polyvinylidene fluoride resin, dimethylacetamide solvent, and hydroxyethyl cellulose additives sold by Kureha under the trade name PVDF in a weight ratio of 14:78:2, stir them evenly with a mechanical mixer, and then use a decompression Carry out defoaming, and the film-making feed liquid made after defoaming is placed in the feed liquid tank;

[0120] Next, prepare the gel bath:

[0121] The dimethylacetamide solvent, water and potassium persulfate oxidizing agent are formulated into a mixed solution in a weight ratio of 5:85:10, which is used as a gel bath for circulation.

[0122] Then, under the same conditions as in Example 1, a polyvinylidene fluoride hollow fiber membrane with a substrate was produced.

[0123] The performance of the polyvinylidene fluoride hollow fiber membrane with substrate obtained is as follows:

[0124] The average pore diameter of the obtained hollow fiber membrane was measur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com