Expanded and vitrified small ball wall self-insulation system

A technology of expanding vitrified microbeads and self-insulation, applied in insulation, walls, solid waste management, etc., to achieve the effects of low water absorption, good flexibility and crack resistance, and high fire protection rating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0038] Expansion vitrified microbead thermal insulation blocks: 19 parts of cement, 15 parts of fly ash, 6 parts of expanded vitrified microbeads, 5 parts of slag, 4 parts of quartz sand, 16 parts of rice seeds, and 35 parts of water.

[0039] Masonry mortar with expanded vitrified beads: 30 parts of cement, 20 parts of quartz sand, 9 parts of expanded vitrified beads, 0.27 parts of redispersible rubber powder, 0.2 parts of enhanced anti-cracking agent, 0.03 parts of air-entraining agent, water retention 0.5 parts of agent, 40 parts of water.

[0040] Expansion vitrified microbead thermal insulation template: 48 parts of cement, 15 parts of expanded vitrified microbeads, 0.21 parts of redispersible rubber powder, 0.4 parts of anti-cracking enhancer, 0.04 parts of air-entraining agent, 0.25 parts of water-retaining agent, water reducing 0.1 parts of enhancer, 36 parts of water.

example 2

[0042] Expansion vitrified microbead insulation blocks: 20 parts of cement, 14 parts of fly ash, 6 parts of expanded vitrified microbeads, 6 parts of slag, 3 parts of quartz sand, 16 parts of rice seeds, and 35 parts of water.

[0043] Masonry mortar with expanded vitrified beads: 29 parts of cement, 19 parts of quartz sand, 10 parts of expanded vitrified beads, 0.27 parts of redispersible rubber powder, 0.2 parts of enhanced anti-cracking agent, 0.03 parts of air-entraining agent, water retention 0.5 part of agent, 39 parts of water.

[0044]Expansion vitrified microbead thermal insulation template: 47 parts of cement, 16 parts of expanded vitrified microbeads, 0.16 parts of redispersible rubber powder, 0.5 parts of anti-cracking enhancer, 0.04 parts of air-entraining agent, 0.2 parts of water-retaining agent, water reducing 0.1 parts of enhancer, 36 parts of water.

example 3

[0046] Expansion vitrified microbead thermal insulation blocks: 21 parts of cement, 14 parts of fly ash, 6 parts of expanded vitrified microbeads, 4 parts of slag, 3 parts of quartz sand, 17 parts of rice seeds, and 35 parts of water.

[0047] Masonry mortar with expanded vitrified microbeads: 28 parts of cement, 21 parts of quartz sand, 10 parts of expanded vitrified microbeads, 0.3 parts of redispersible rubber powder, 0.2 parts of enhanced anti-cracking agent, 0.03 parts of air-entraining agent, water retention agent 0.47 parts, 40 parts of water.

[0048] Expansion vitrified microbead thermal insulation template: 50 parts of cement, 14 parts of expanded vitrified microbeads, 0.23 parts of redispersible rubber powder, 0.4 parts of anti-cracking enhancer, 0.04 parts of air-entraining agent, 0.23 parts of water-retaining agent, water reducing 0.1 part of enhancer, 35 parts of water.

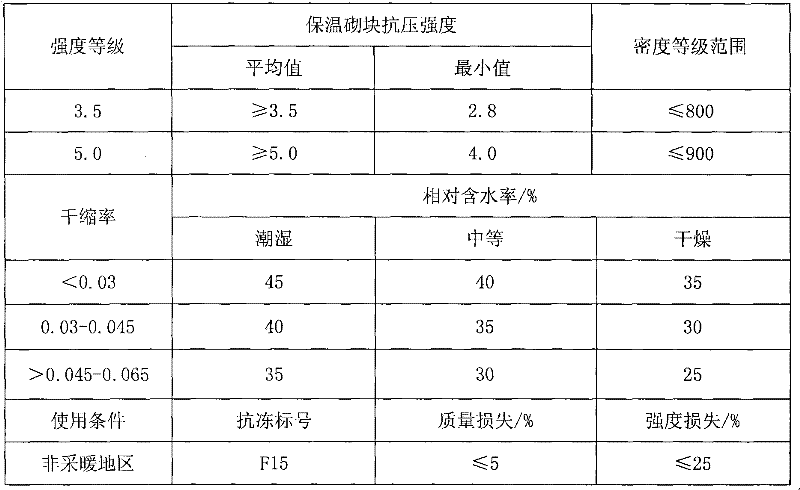

[0049] Table 1

[0050]

[0051]

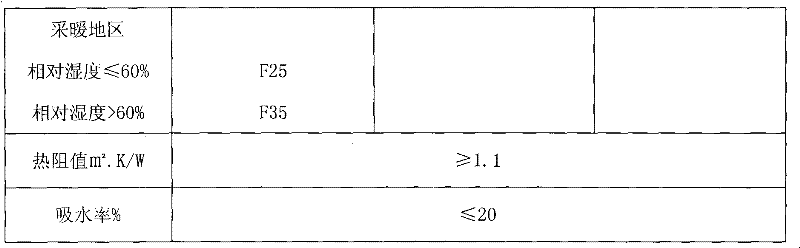

[0052] Table 2

[0053]

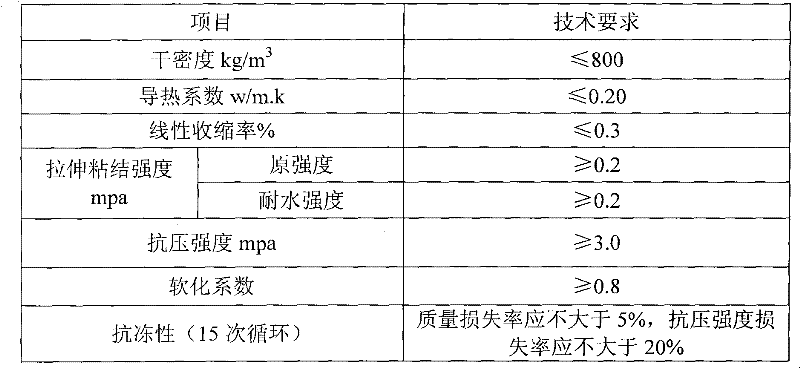

[0054] table 3

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com