Method for directional thermal degradation of fiber biomass

A technology of thermal degradation and biomass, applied in the direction of organic chemistry, etc., can solve the problems of poor product stability and complex components of thermal degradation products, so as to increase the dosage, increase the content of furfural and levoglucose, and reduce the content of levoglucose Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

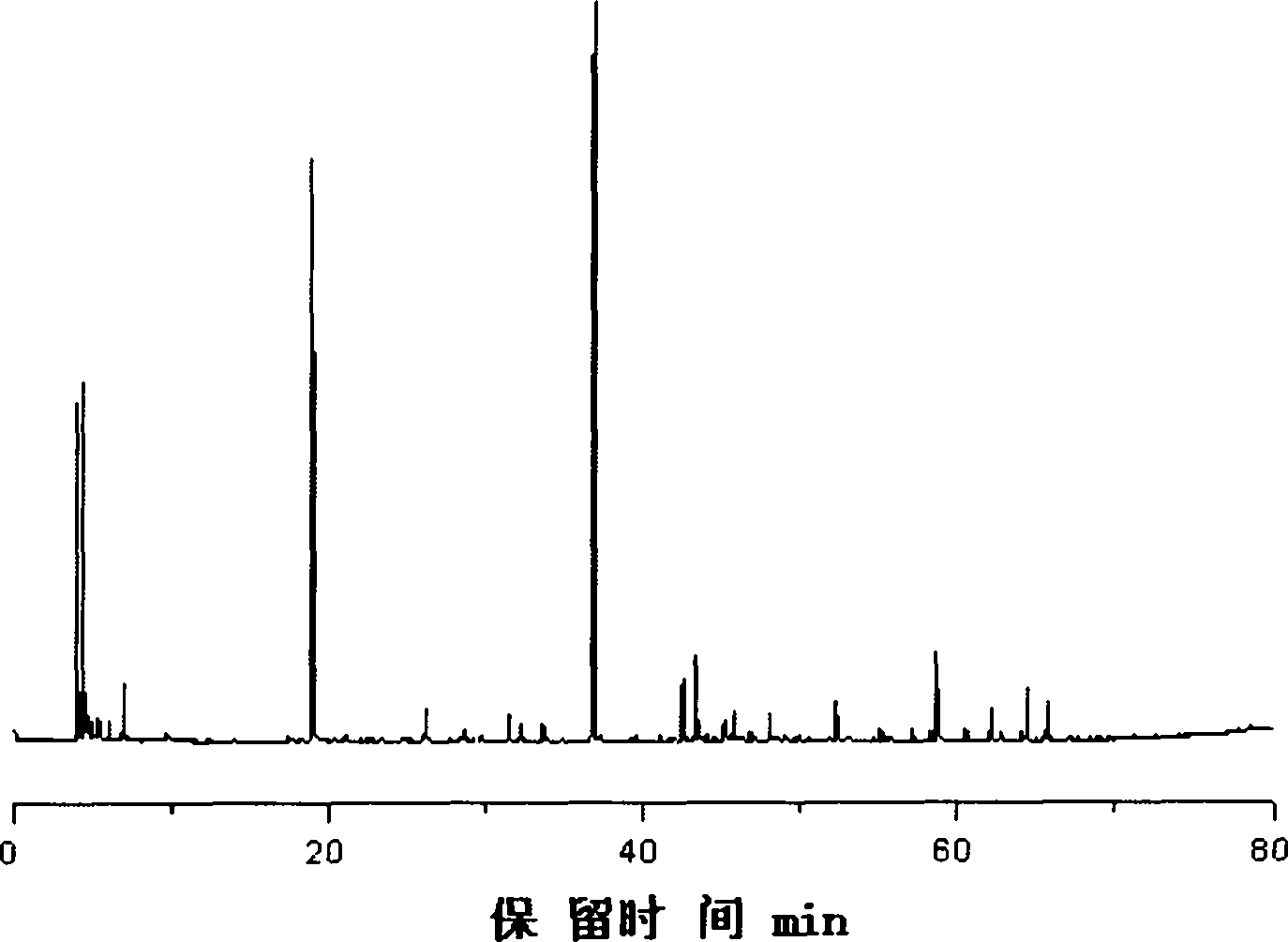

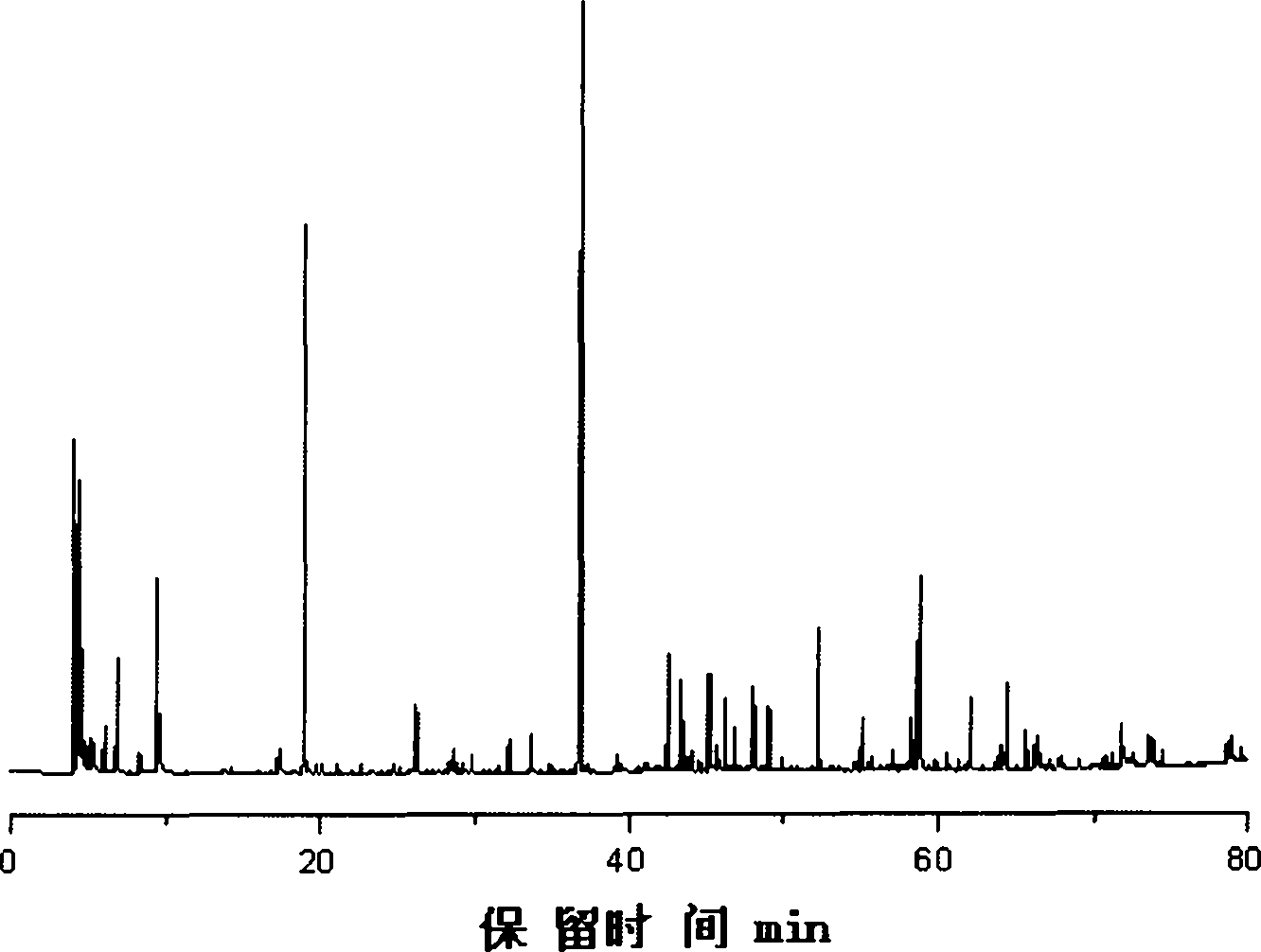

[0028] Grind the bamboo biomass raw material to 0.05-0.2 mm, add 3.0 g of bamboo powder and 150 ml of phosphoric acid solution with a mass concentration of 5.0% in a single-necked flask equipped with a condenser, heat and reflux for 1 h, filter and use hot Wash three times with deionized water and dry in an oven at 100 °C. The pretreated bamboo powder is quickly put into the fixed bed cracking reaction furnace which has reached 500°C, and the liquid product is collected through a cold trap. Analysis results of the liquid product: furfural content was 23.0%, levoglucose content was 45.20%, and levoglucosan content was 4.08%.

Embodiment 2

[0030] Grind the bamboo biomass raw material to 0.05-0.2 mm, add 3.0 g of bamboo powder and 150 ml of phosphoric acid solution with a mass concentration of 2.5% in a single-necked flask equipped with a condenser, heat and reflux for 1 h, filter and use hot Wash three times with deionized water and dry in an oven at 100 °C. The pretreated bamboo powder is quickly put into the fixed bed cracking reaction furnace which has reached 500°C, and the liquid product is collected through a cold trap. Analysis results of the liquid product: the content of furfural was 18.3%, the content of levoglucose was 38.7%, and the content of levoglucose was 13.0%.

Embodiment 3

[0032] Grind the bamboo biomass raw material to 0.05-0.2 mm, add 3.0 g of bamboo powder and 150 ml of phosphoric acid solution with a mass concentration of 1.0% in a single-necked flask equipped with a condenser tube, heat and reflux for pretreatment for 1 hour, filter and use a hot Wash three times with deionized water and dry in an oven at 100 °C. The pretreated bamboo powder is quickly put into the fixed bed cracking reaction furnace which has reached 500°C, and the liquid product is collected through a cold trap. Analysis results of the liquid product: furfural content was 13.8%, levoglucose content was 29.5%, and levoglucose content was 13.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com