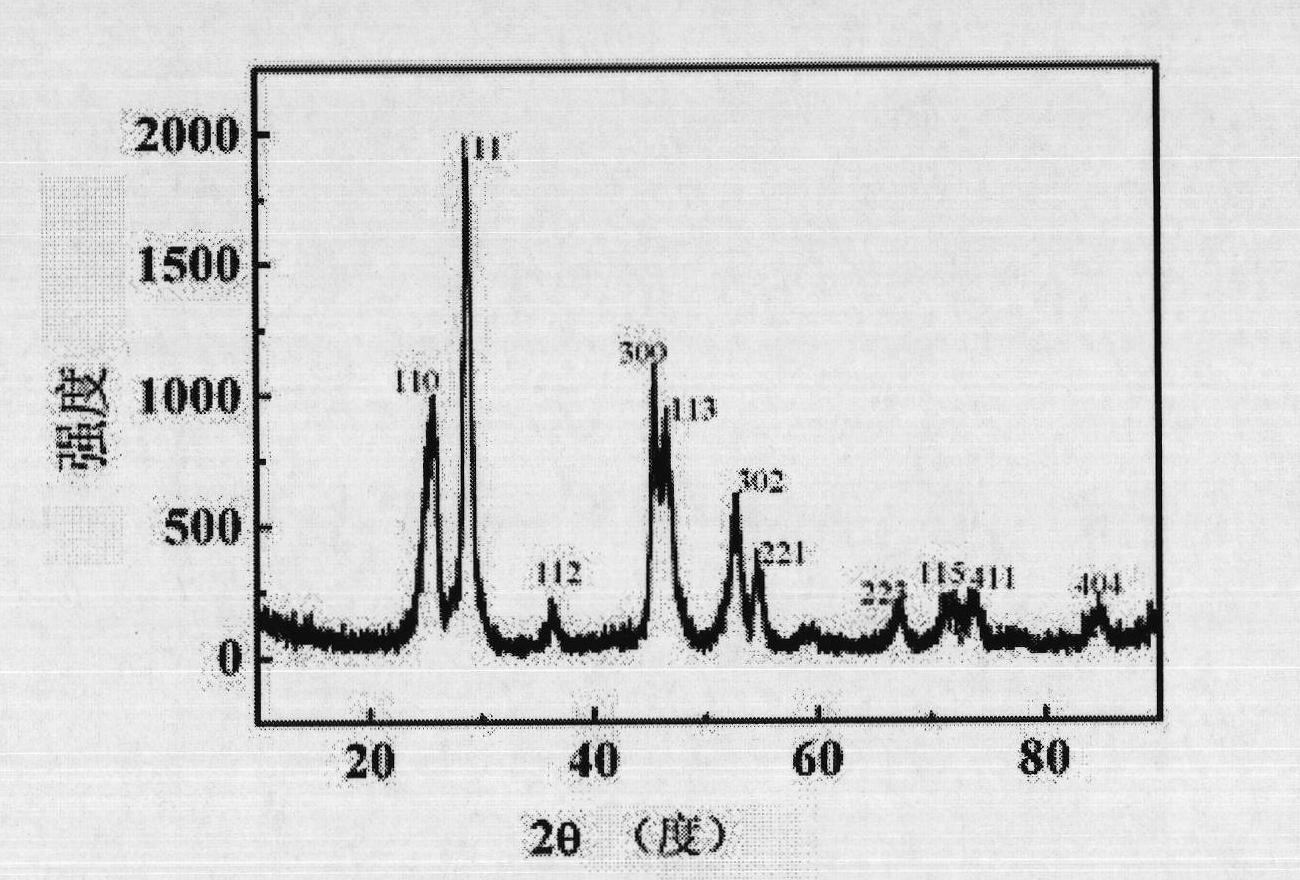

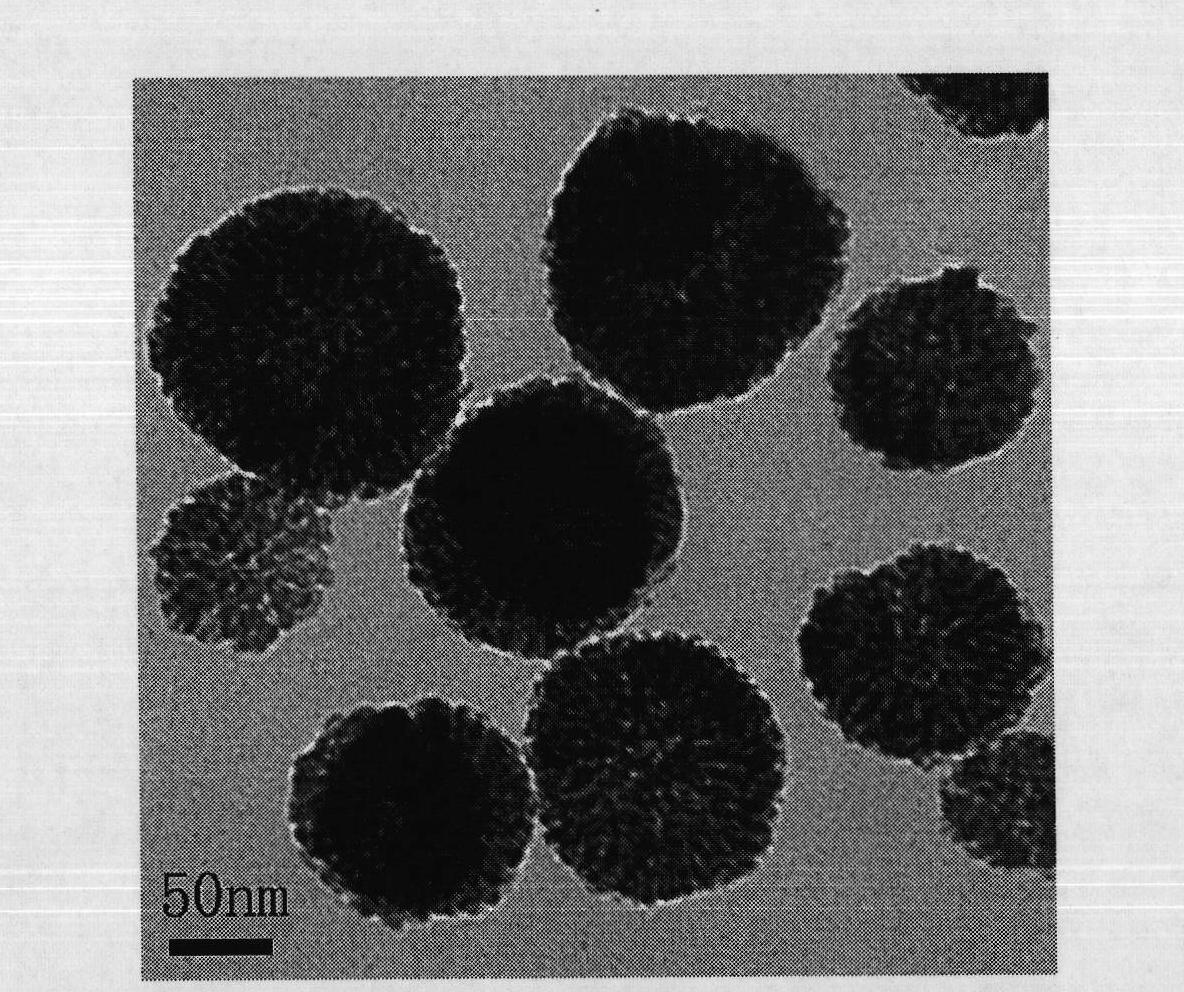

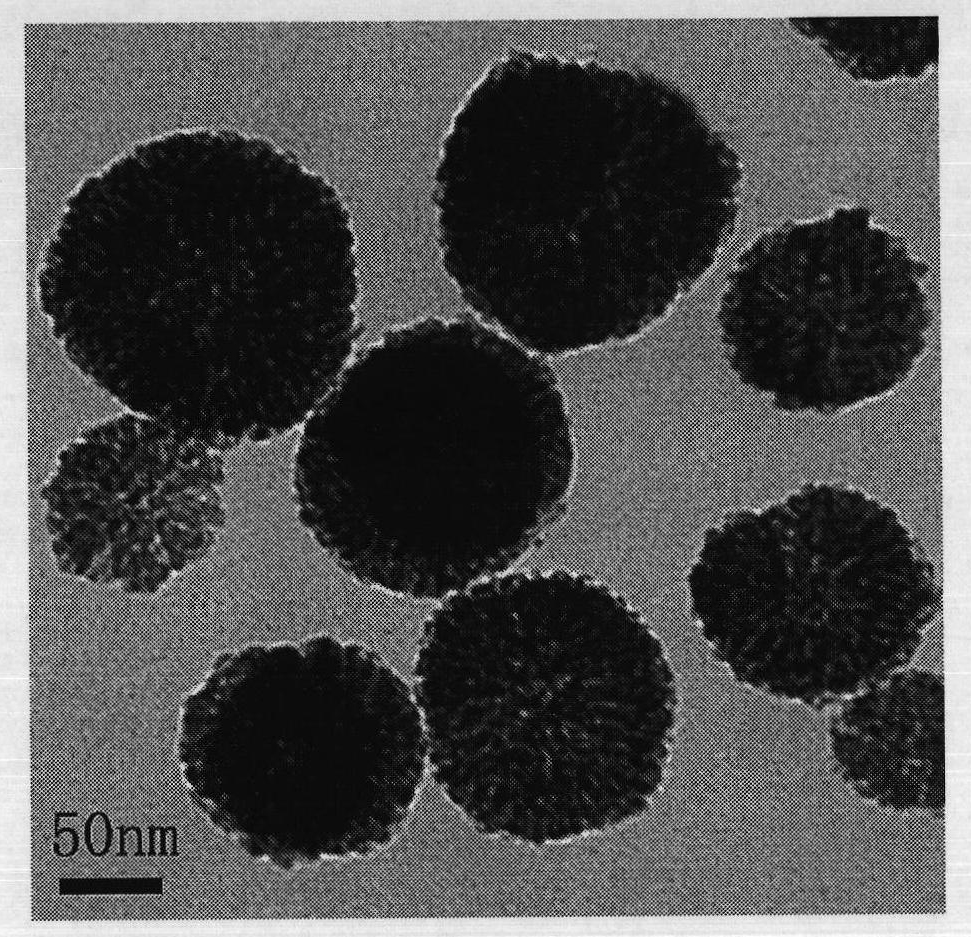

Method for preparing rare-earth fluoride nanometer mesoporous spheres

A rare earth fluoride and nano-mesoporous technology, which is applied in the fields of rare earth metal compounds, microsphere preparation, chemical instruments and methods, etc., can solve the problems of difficult expansion of production scale, numerous and complicated procedures, and reduced synthesis efficiency, and achieves easy recovery, Simple process and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Sonicate 7.5mL of absolute ethanol and 7.5mL of 1-butyl-3-methylimidazolium tetrafluoroboric acid for 5min to form a colorless and transparent solution, dissolve 2mmol of europium nitrate in the above mixed solution, stir at room temperature for 24h, and centrifuge the product , washed with deionized water until neutral, washed with absolute ethanol, and dried at 60°C to obtain europium fluoride nanometer mesoporous spheres.

Embodiment 2

[0022] Sonicate 7.5mL of absolute ethanol and 7.5mL of 1-butyl-3-methylimidazolium tetrafluoroboric acid for 5min to form a transparent solution, dissolve 1mmol of cerium nitrate in the above mixed solution, stir at room temperature for 24h, and use deionized Wash with water until neutral, wash with absolute ethanol, and dry at 60°C to obtain cerium fluoride nanometer mesoporous spheres.

Embodiment 3

[0024] 7.5mL of absolute ethanol and 7.5mL of 1-butyl-3-methylimidazolium tetrafluoroboric acid were sonicated for 5min to form a colorless and transparent solution, 2.5mmol of samarium nitrate was dissolved in the above mixed solution, stirred at room temperature for 48h, and the product was centrifuged , washed with deionized water until neutral, washed with absolute ethanol, and dried at 60°C to obtain samarium fluoride nanometer mesoporous spheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com