Manufacturing method of environment-friendly antiflaming middle and high density fiberboard

A high-density fiberboard and manufacturing method technology, applied in the field of fiberboard manufacturing, can solve the problems of high formaldehyde mole, carcinogenic effect, complex manufacturing process, etc., and achieve the effects of high added value, low production cost, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

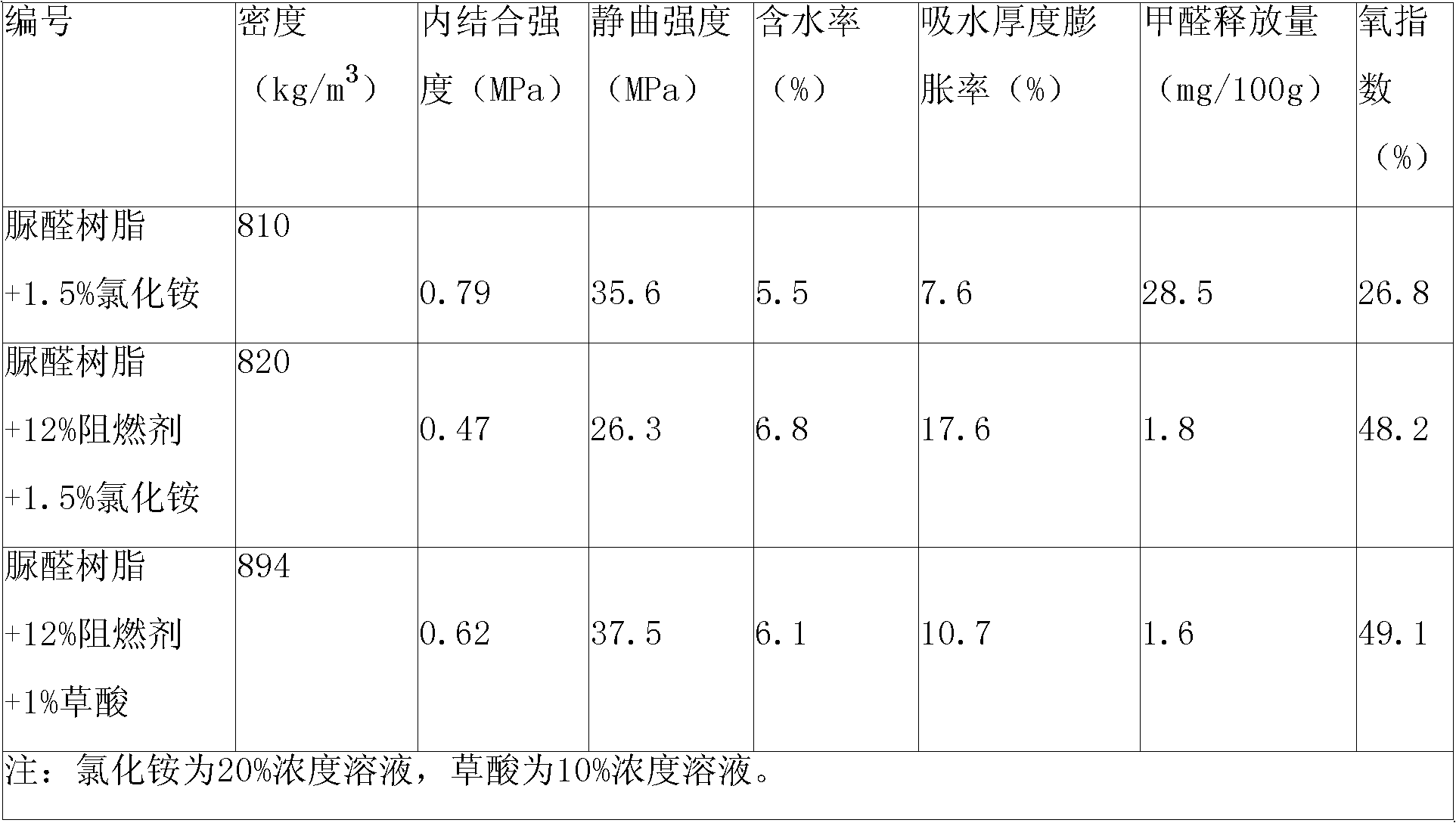

Embodiment 1

[0033] Manufacturing method of environmentally friendly flame-retardant medium density fiberboard with a format of 1220×2440×10mm:

[0034] 1. Fiber preparation: use wood or non-wood materials such as waste wood, branch wood, bark, and secondary small-diameter wood as raw materials, and prepare the required fiber after cutting, planing or chipping, sorting, washing, softening, and heat grinding. of fiber.

[0035] 2. Flame retardant treatment: use the pipeline sizing method, use a separate metering system to send the flame retardant with a pH value of 7 to 8 into the discharge valve of the heat refiner, and the amount of the flame retardant is 13% of the dry fiber weight , The flame retardant is a liquid with a concentration of 50%.

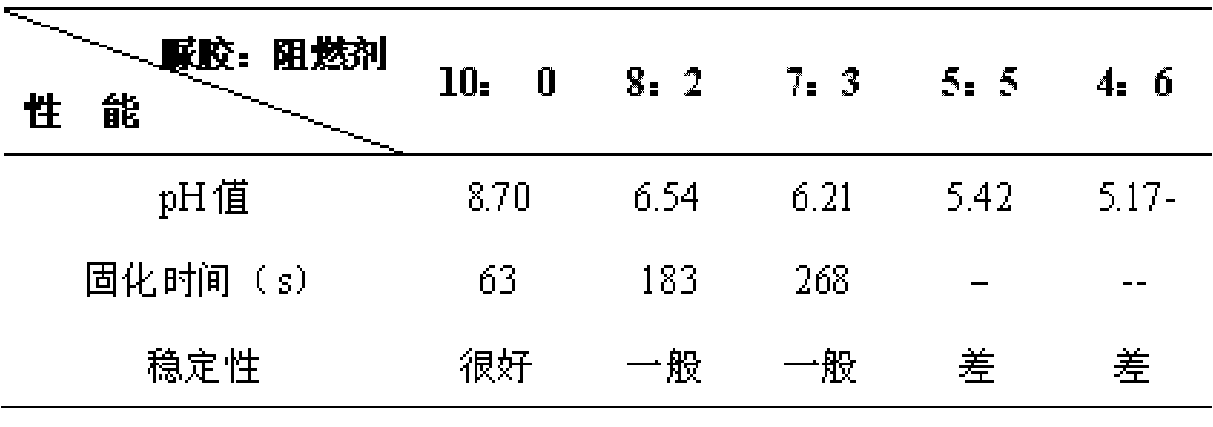

[0036] 3. Sizing and waterproofing agent: add curing agent to urea-formaldehyde resin to adjust the glue. The curing agent is 10% oxalic acid solution, and the amount added is 1% of the weight of the glue; use the pipeline sizing method and use ...

Embodiment 2

[0042] Manufacturing method of environmentally friendly flame-retardant high-density fiberboard with a format of 1220×2440×15mm:

[0043] 1. Fiber preparation: use wood or non-wood materials such as waste wood, branch wood, bark, and secondary small-diameter wood as raw materials, and prepare the required fiber after cutting, planing or chipping, sorting, washing, softening, and heat grinding. fiber;

[0044] 2. Flame retardant treatment: use the pipeline sizing method, use a separate metering system to send the flame retardant with a pH value of 7 to 8 into the discharge valve of the heat refiner, and the amount of the flame retardant is 15% of the dry fiber weight , The flame retardant is a liquid with a concentration of 50%.

[0045] 3. Sizing and waterproofing agent: add curing agent to urea-formaldehyde resin to adjust the glue. The curing agent is 10% oxalic acid solution, and the amount added is 1% of the weight of the glue; use the pipeline sizing method and use two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com