Method for recovering sulfur dioxide from flue gas and producing hydroxylamine sulphate and system thereof

A technology of hydroxylamine sulfate and sulfur dioxide, which is applied in the fields of environmental protection and chemical engineering, can solve the problems that the value of sulfur resources has not been fully reflected, the sales volume of chemical fertilizers is limited, and the amount of coal burned is large. promising effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

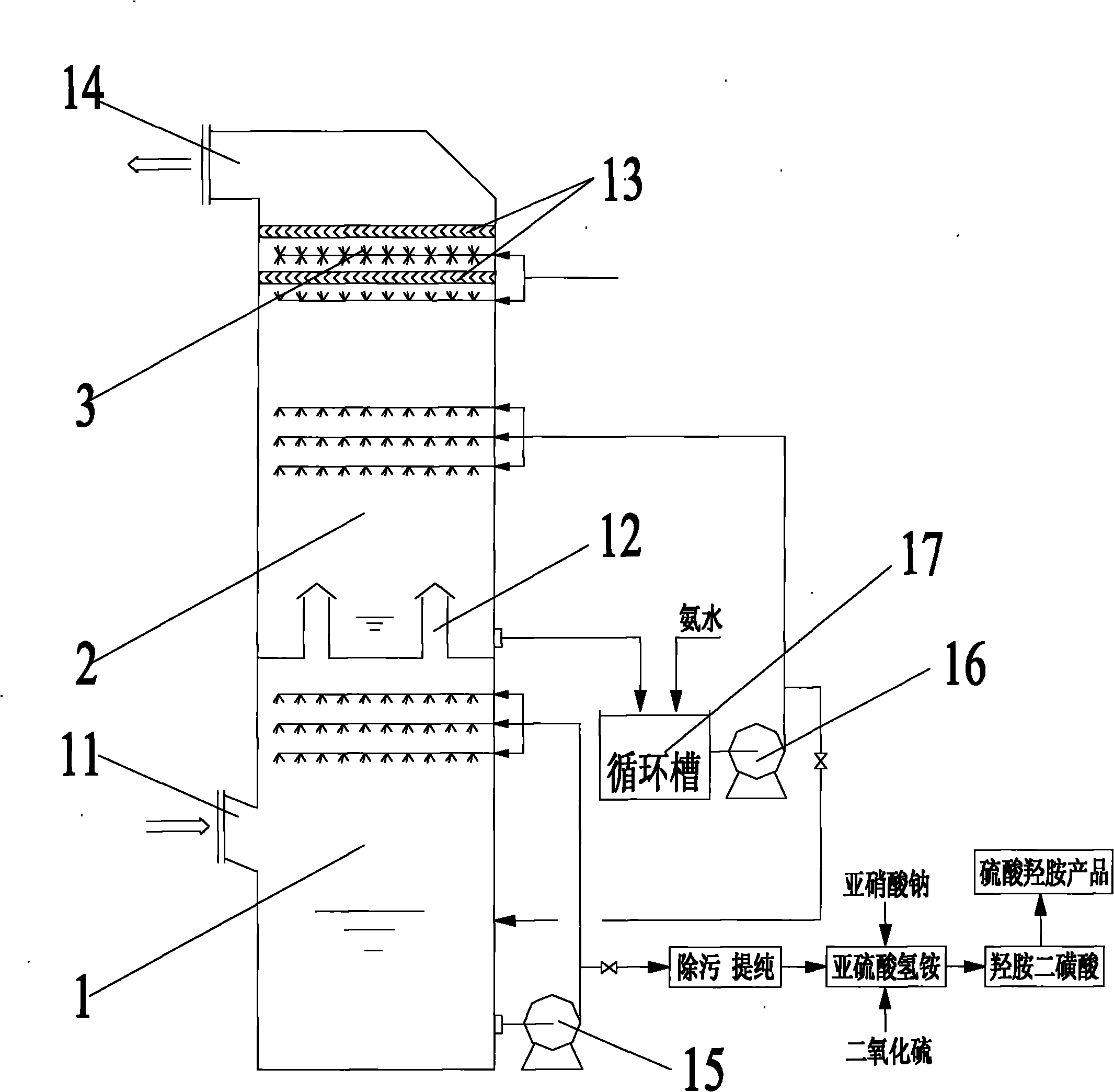

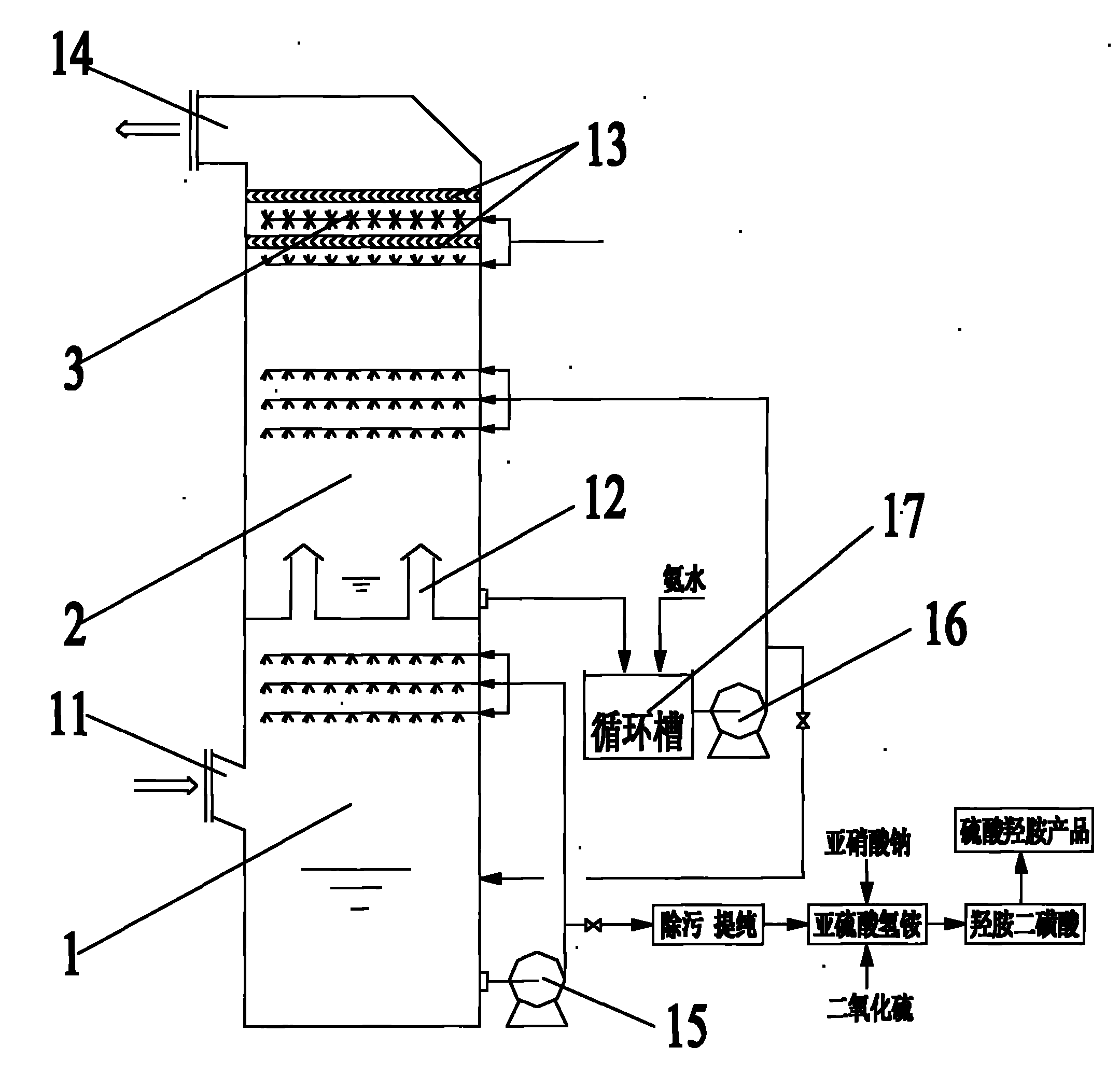

[0027] Refer to figure 1 , The method for recovering sulfur dioxide from flue gas and producing hydroxylamine sulfate, after flue gas enters the desulfurization unit, includes the following steps: A.NH 4 HSO 3 Concentration process: flue gas first enters NH through flue gas inlet 11 4 HSO 3 Concentration section 1, the liquid-gas ratio of circulating spray in this section is 3~15L / m 3 , The flue gas temperature is reduced to 85~70℃, and the pH of the circulating fluid is controlled at 4.5~5.5, so that the (NH 4 ) 2 SO 3 More converted to NH 4 HSO 3 To make NH 4 HSO 3 It accounts for an absolute proportion in the circulating fluid, which is derived from SO 2 Circulation tank 17 of main absorption section 2; B.SO 2 Main absorption process: After NH 4 HSO 3 The flue gas in the concentration section 1 is sufficiently cooled and humidified, and enters the SO through the air lift cap 12 2 Main absorption section 2, this section is used to elute SO 2 For the main purpose, NH in the circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com