Improved production and in vivo assembly of soluble recombinant icosahedral virus-like particles

A recombinant virus, soluble technology, applied in the direction of virus/phage, virus, virus peptide, etc., can solve the problem of icosahedral virus CP-peptide fusion particle assembly and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

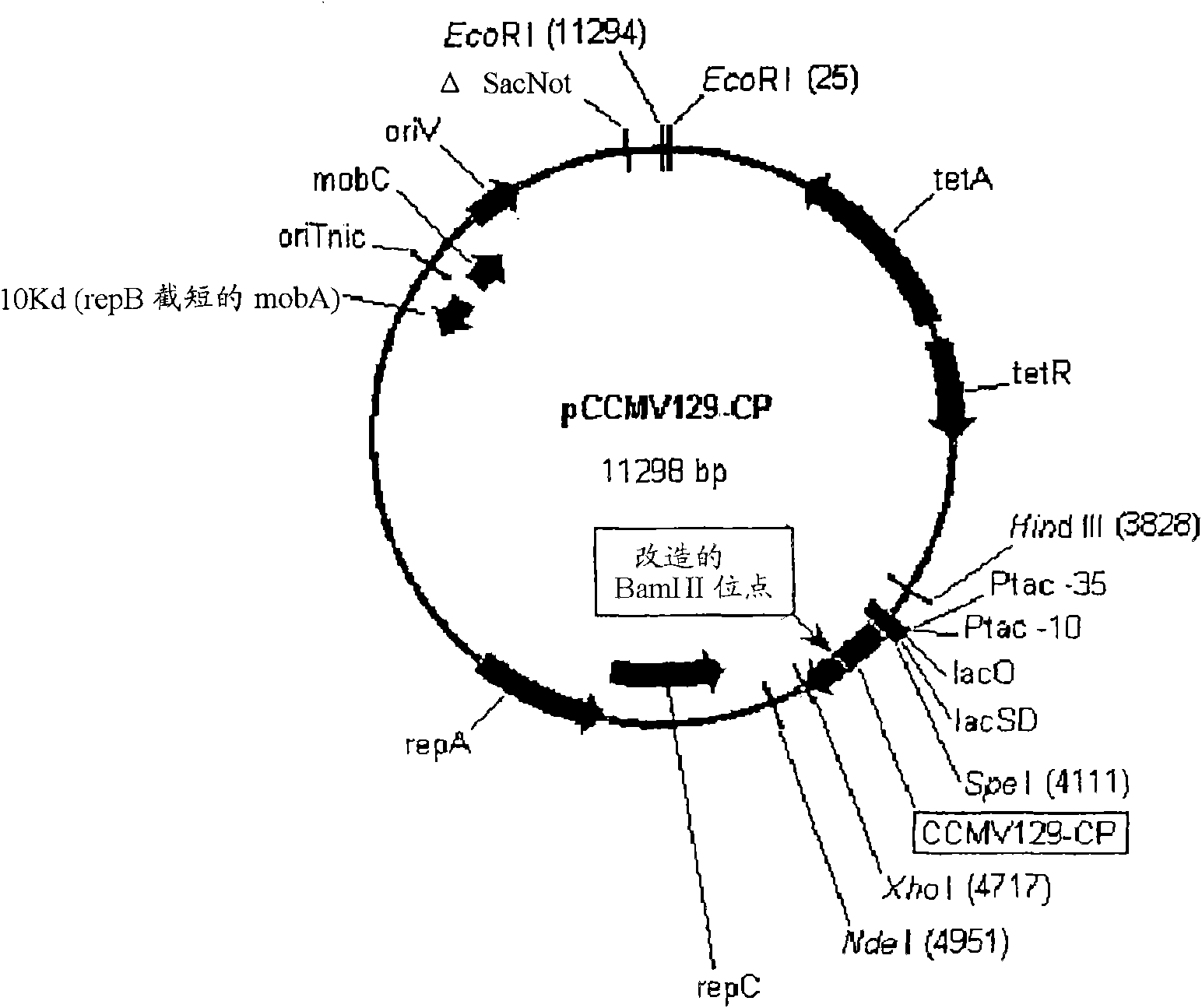

[0318] Example 1: Cloning of expression plasmids for expression of codon- and hydrophilicity-optimized CCMV capsid proteins in Pseudomonas fluorescens

[0319] clone:

[0320]A codon and hydrophobicity optimized CCMV CP nucleotide sequence (SEQ ID NO: 3) was designed. A shuttle plasmid (DNA 2.0, MenloPark, CA). The insert was gel purified on a 1% agarose gel and ligated into vector pDow1169 (a medium copy plasmid with RSF1010 origin, pyyF, tac promoter, and rrnBT1T2 terminator from pKK223-3 (PL-Pharmacia)) to create an expression plasmid (SEQ ID NO: 23) for expression of CCMV CP in Pseudomonas fluorescens. After purification with a Micro Bio-spin 6 column, the ligated product was transformed into Pseudomonas fluorescens strain DC454 (ΔpyrFRXF01414(lsc)::lacIq1) by electroporation. After shaking in LB medium at 30°C for 2 hours, the transformants were plated on M9 glucose plates. The presence of the insert was confirmed by restriction digest and sequencing of plasmid DNA i...

Embodiment 2

[0511] Example 2: Introduction of restriction sites into loops of codon and hydrophilicity optimized CCMV capsid proteins

[0512] Site-directed mutagenesis reactions were performed using Quikchange II-XL (Stratagene, TX) according to the manufacturer's protocol. The Pseudomonas fluorescens expression plasmid (SEQ ID NO: 23) containing the codon-optimized CCMV-CP served as template. After purification with Micro Bio-spin 6, the resulting plasmid with the introduced restriction sites was transformed into Pseudomonas fluorescens strain DC454 (ΔpyrF RXF01414(lsc)::lacIq1) by electroporation. Protein expression was performed as described in Example 1.

[0513] Primers used to introduce the blunt-end cleavage restriction site AfeII into loop 63:

[0514] CCMV-AfeI-63-F (SEQ ID NO: 24): 5'-TGCGCGGCTGCCGAGAGCGCTGCCAAGGTCACCAGT-3'

[0515] CCMV-AfeI-63-R (SEQ ID NO: 25): 5'-ACTGGTGACCTTGGCAGCGCTCTCGGCAGCCGCGCA-3'

[0516] Primers used to introduce the 3' overhang cleavage restrict...

Embodiment 3

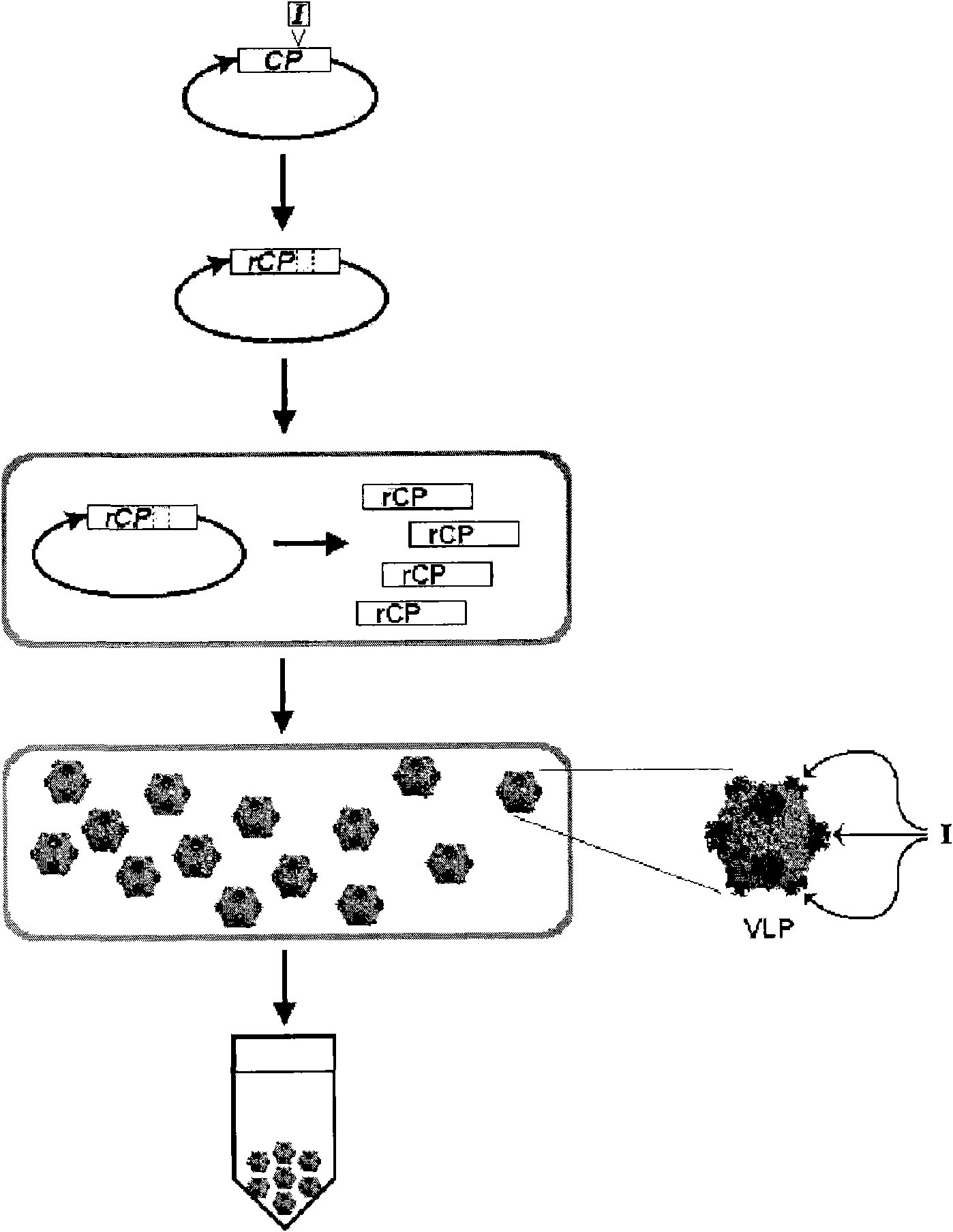

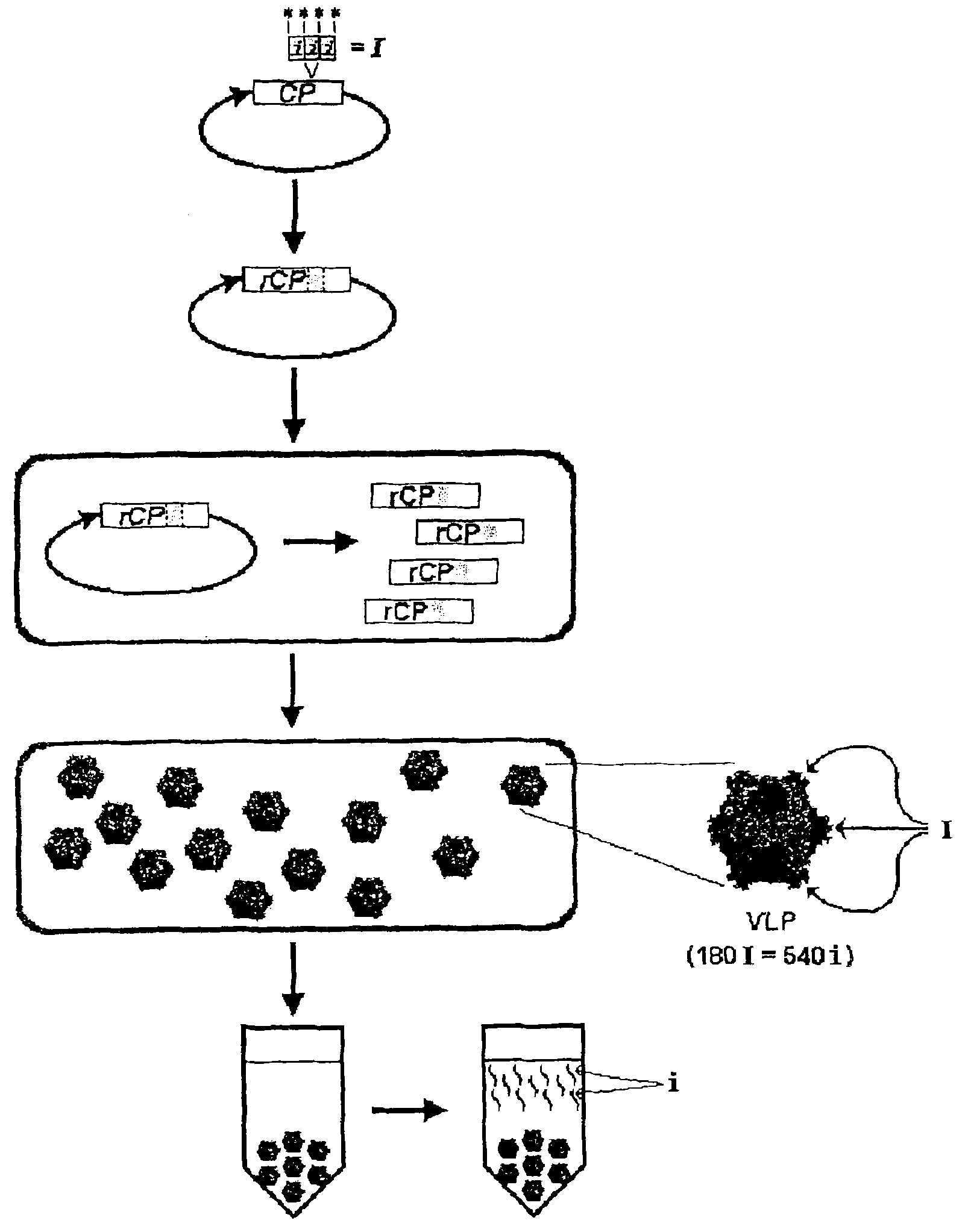

[0528] Example 3: Restriction digest based cloning and expression of influenza vaccine M2e peptide fused to the codon and hydrophilicity optimized 129 surface loop of the CCMV capsid protein

[0529] Peptide Synthesis:

[0530] Inserts were synthesized by overlapping DNA oligonucleotides described below and the thermal cycling procedure detailed below:

[0531]

[0532]

[0533] *(from Invitrogen Corp, Carlsbad, CA)

[0534] use PCR purification kit (Qiagen) purified PCR products, digested with XbaI (NEB), and The kit was purified again and ligated with T4 DNA ligase (NEB) into the XbaI-restricted CCMV CP Pseudomonas fluorescens expression vector (from Example 2) containing the XbaI restriction site in loop 129 point. After purification with a Micro Bio-spin 6 column (Biorad), the ligated product was transformed into Pseudomonas fluorescens strain DC454 (ΔpyrFRXF01414(lsc)::lacIq1) by electroporation. After shaking in LB medium at 30°C for 2 hours, the transforman...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com