Method and device capable of inhibiting refuse incineration from generating dioxins

A technology of waste incineration and waste incinerator, which is applied in the direction of combustion methods, lighting and heating equipment, incinerators, etc. It can solve the problems of dioxins being discharged into the atmosphere, activated carbon cannot be regenerated, and there are many flue gas purification equipment, etc., and the operating cost is achieved. Low, good aerodynamic field, increased strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

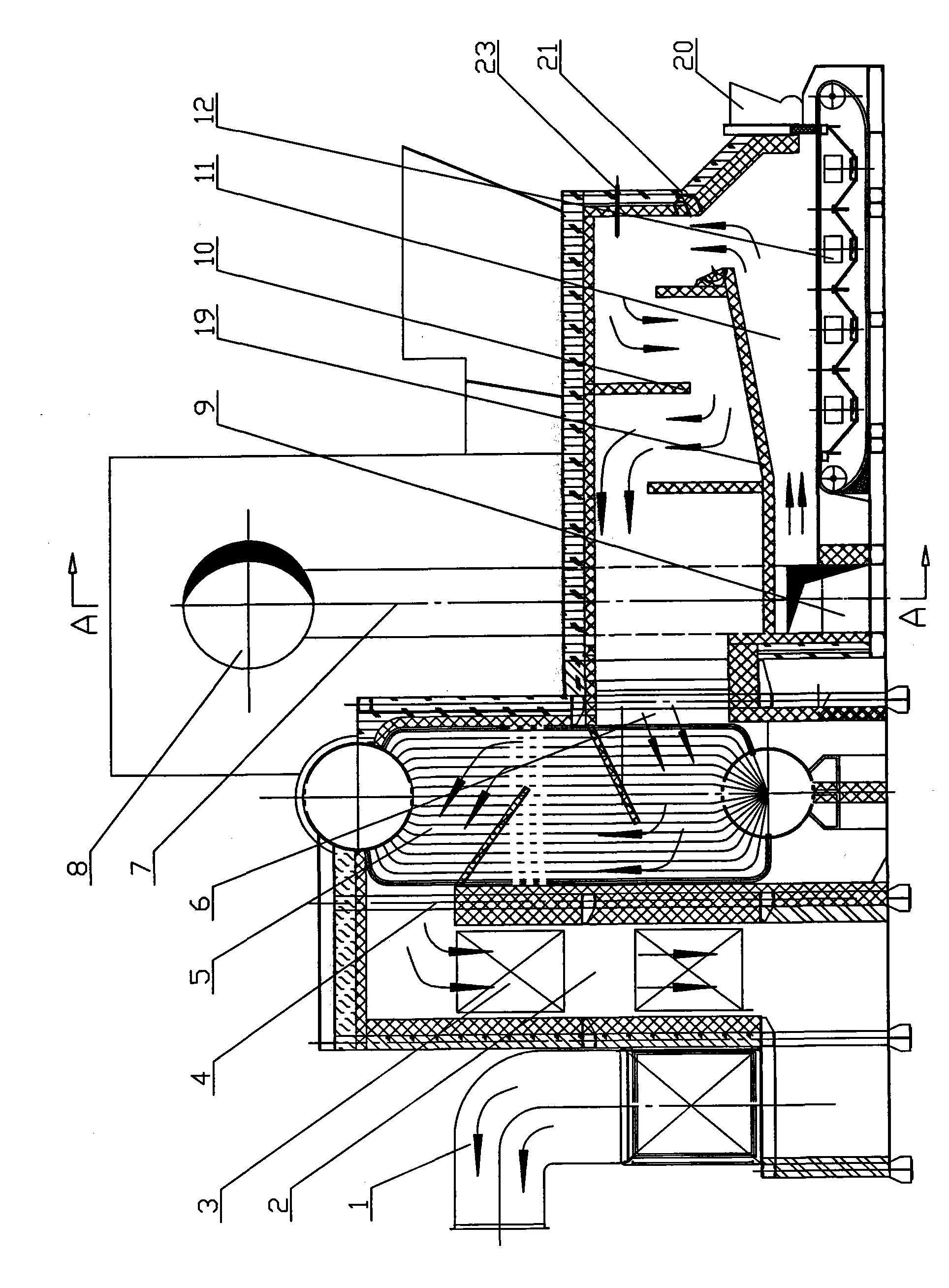

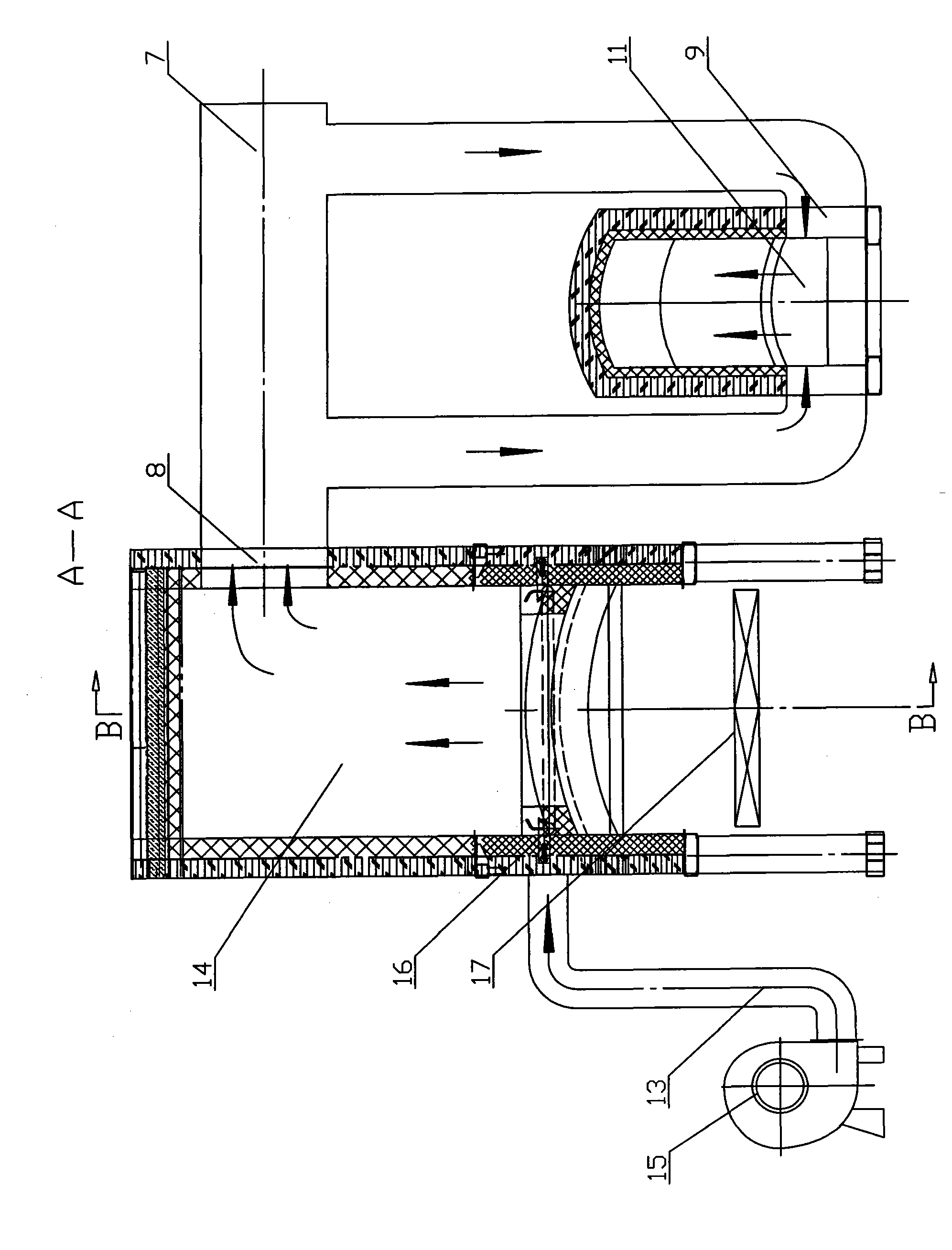

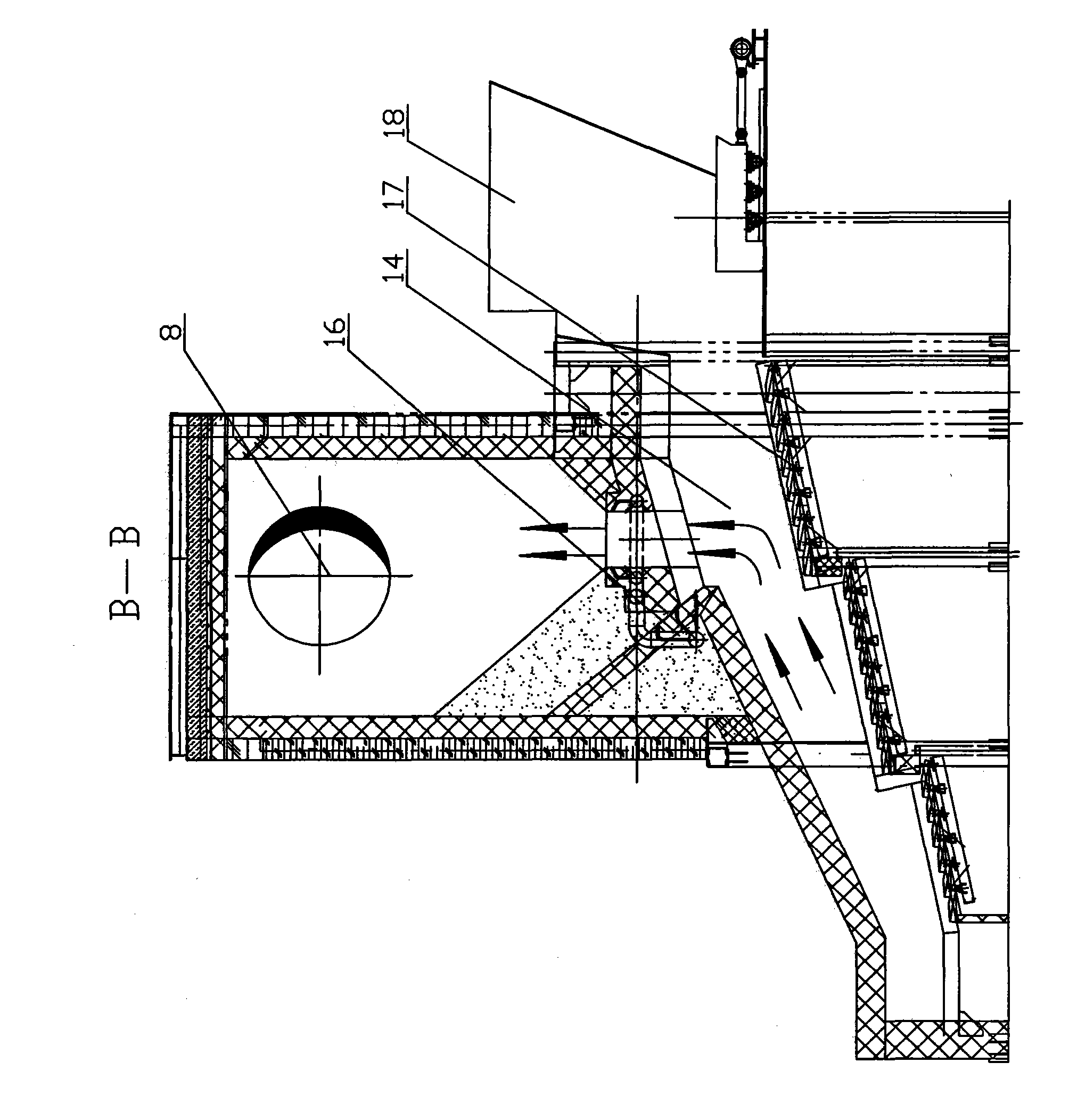

[0025] Below in conjunction with accompanying drawing and embodiment this technical scheme is described further:

[0026] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the garbage incinerator and the secondary heating furnace are arranged side by side, and the waste incinerator flue gas outlet 8 above the garbage incinerator hearth 14 is directly connected with the flue 7, and the other end of the flue 7 is connected to the secondary heating furnace afterbody. The flue gas inlet 9 of the secondary heating furnace is connected; a secondary wind box 16 is set around the furnace arch of the waste incinerator, and the distance between the front and rear arches is shorter than that of the traditional waste incinerator; the daily processing of 200t of waste Take the incinerator as an example, the distance between the front and rear arches is 1.1m; a temperature measuring point 23 is set at the front wall of the furnace body of the secondary heating furnace, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com