Poly-lactic acid fiber loading powder drug and preparation method thereof

A technology of polylactic acid fiber and polylactic acid, which is applied in the field of drug-loaded polylactic acid fiber and its preparation, can solve the problems of insoluble solid powder drugs and achieve the effect of controlled release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step (1) Prepare 2 milliliters of an aqueous solution of 0.01 g / mL sodium alginate.

[0028] Step (2) Add 0.03 g of talcum powder (powder type drug) to (1), and stir for 5 minutes.

[0029] Step (3) Add 1 g of AOT (surfactant) and 25 mL of dichloromethane to (2), and stir for 5 minutes.

[0030] Step (4) Add 0.05 g of calcium chloride to (3), stir ultrasonically for 15 minutes, and solidify, so that the talcum powder is trapped in the calcium alginate droplet.

[0031] Step (5) Prepare 20 mL of a 0.01 g / mL polylactic acid solution with a molecular weight of 70,000, and the solvent is dichloromethane.

[0032] Step (6) Mix (4) and (5) and stir evenly to obtain an electrospun emulsion.

[0033] In step (7), the electrostatic emulsion electrospinning is performed at a voltage of 10.88KV, an electrode distance of 8cm, and a rate of 0.4mL / h, and the electrospun filaments are collected on tin foil.

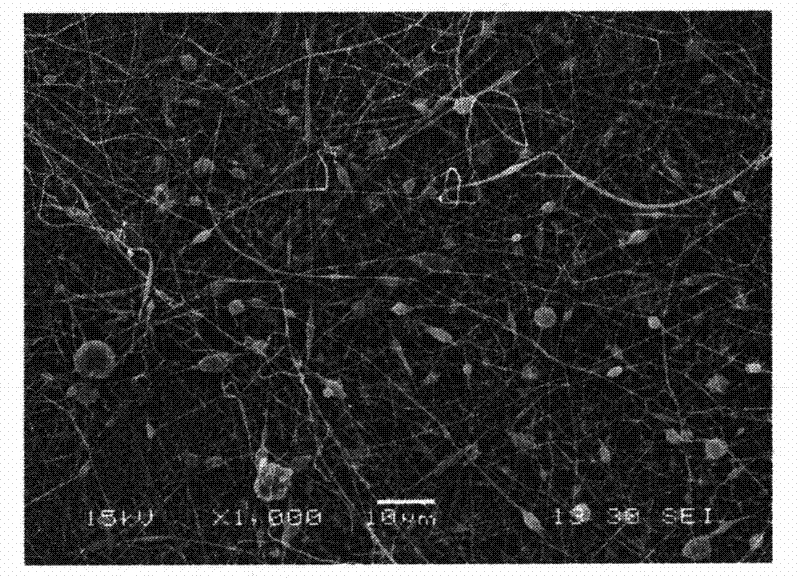

[0034] The average diameter of the obtained drug-loaded (talcum powder) p...

Embodiment 2

[0036] Replace "0.01g / mL sodium alginate aqueous solution 8 ml" in (1) with "0.01g / mL sodium alginate aqueous solution 2 ml", replace (2) with "10g Shengjisan" "0.03g of talc", replace "1g of AOT (surfactant) and 25mL of dichloromethane" in (3) with "5g of polyvinylpyrrolidone (PVP) and 100mL of hexafluoroisopropanol", replace with " The calcium chloride of 5g " replaces " the calcium chloride of 0.05g " in (4), replaces " solvent is dichloromethane " in (5) with " solvent is hexafluoroisopropanol ", all the other repeat in the embodiment Steps (1) to (7), the same method is used to obtain drug-loaded (Shengjisan) polylactic acid fibers with a diameter of 0.15-1 μm and a beaded structure with a diameter of 1-10 μm.

Embodiment 3

[0038] Replace "0.03g of talcum powder" in (2) with "20g of zinc carbonate", and repeat (1) to (7) steps in the examples, and obtain drug-loaded (zinc carbonate) polylactic acid fibers in the same way. The diameter is 0.5-1 μm, and the diameter of the beaded structure is 1-10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com