Preparation process of plant fiber composite materials

A composite material and plant fiber technology, applied in the field of plant fiber composite material manufacturing process, can solve the problems of incorruptibility, difficult plastic material, residue and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

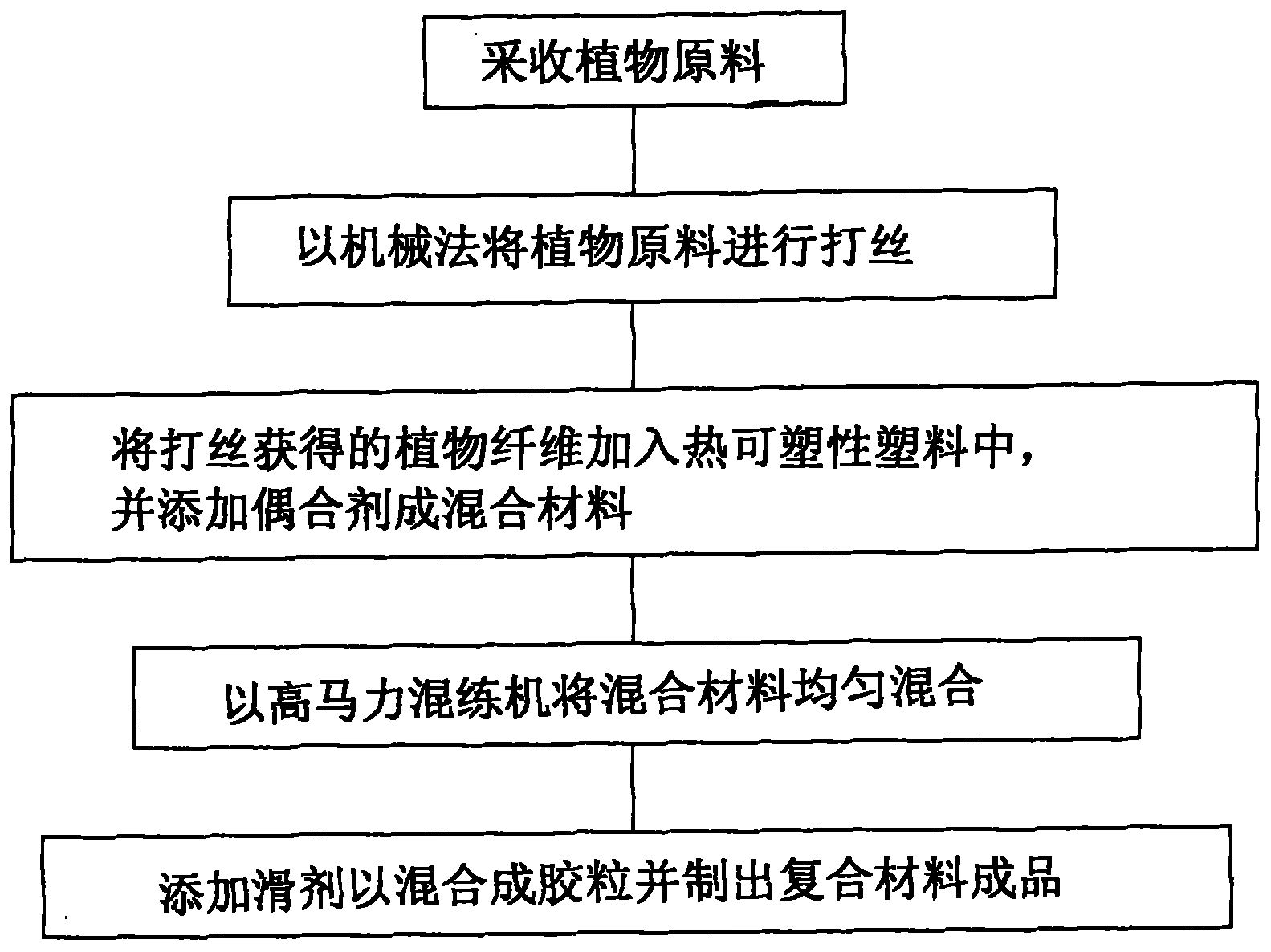

[0019] The present invention relates to a manufacturing process of plant fiber composite material, please refer to figure 1 Shown, it is main embodiment of the present invention, and it comprises the following steps:

[0020] Harvest plant raw materials, the plant raw materials are bamboo or coconut or sugar cane, this embodiment uses bamboo as an illustration, because bamboo must be cut down in an appropriate period after cultivation, so as to avoid the gradual aging and death of bamboo, so bamboo is used as plant raw material mixed with plastic to make products It can reduce the consumption of environmental resources, and the plant raw materials are easy to be decomposed by nature, and will not remain in the living environment for a long time to cause pollution, and the texture of bamboo is tough, not easy to absorb water, and has good heat resistance, so the products made of mixed plastics are also It has the characteristics of high elasticity, easy to decompose, not easy t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com