Unpowered biological filtration tower

A biological filter tower and power technology, applied in sustainable biological treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of high operation and maintenance costs, affecting the surrounding environment, and high operating costs, achieving Improve the hydraulic retention time, increase the specific surface area, and increase the effect of increasing the film hanging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

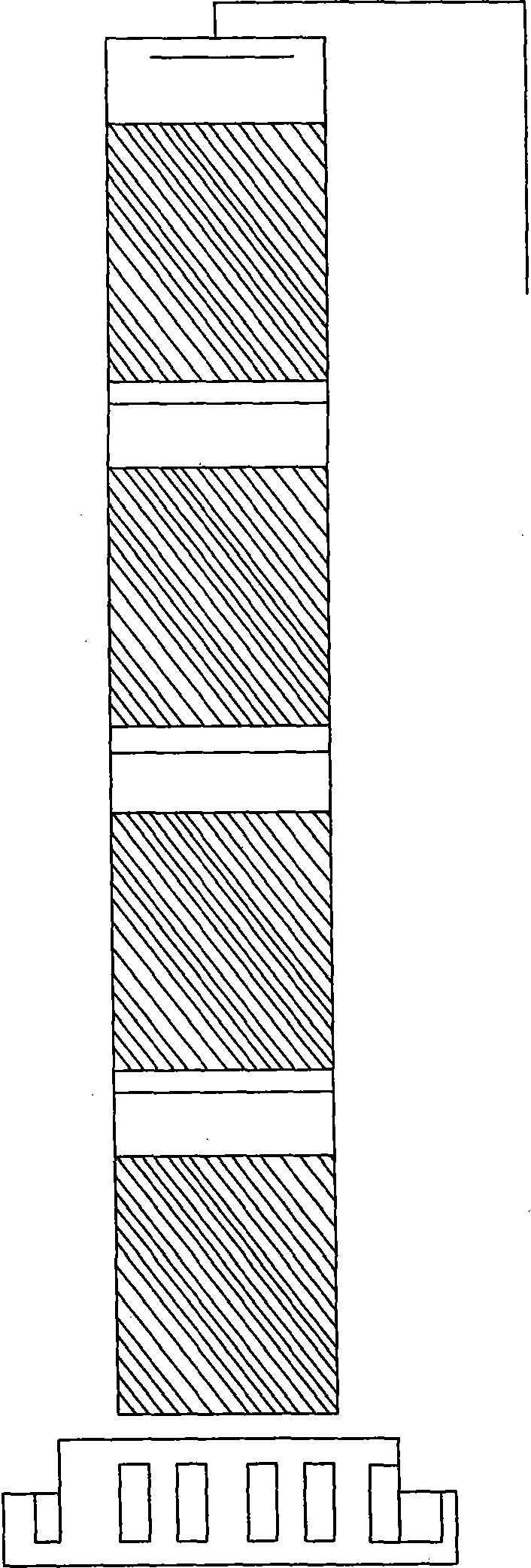

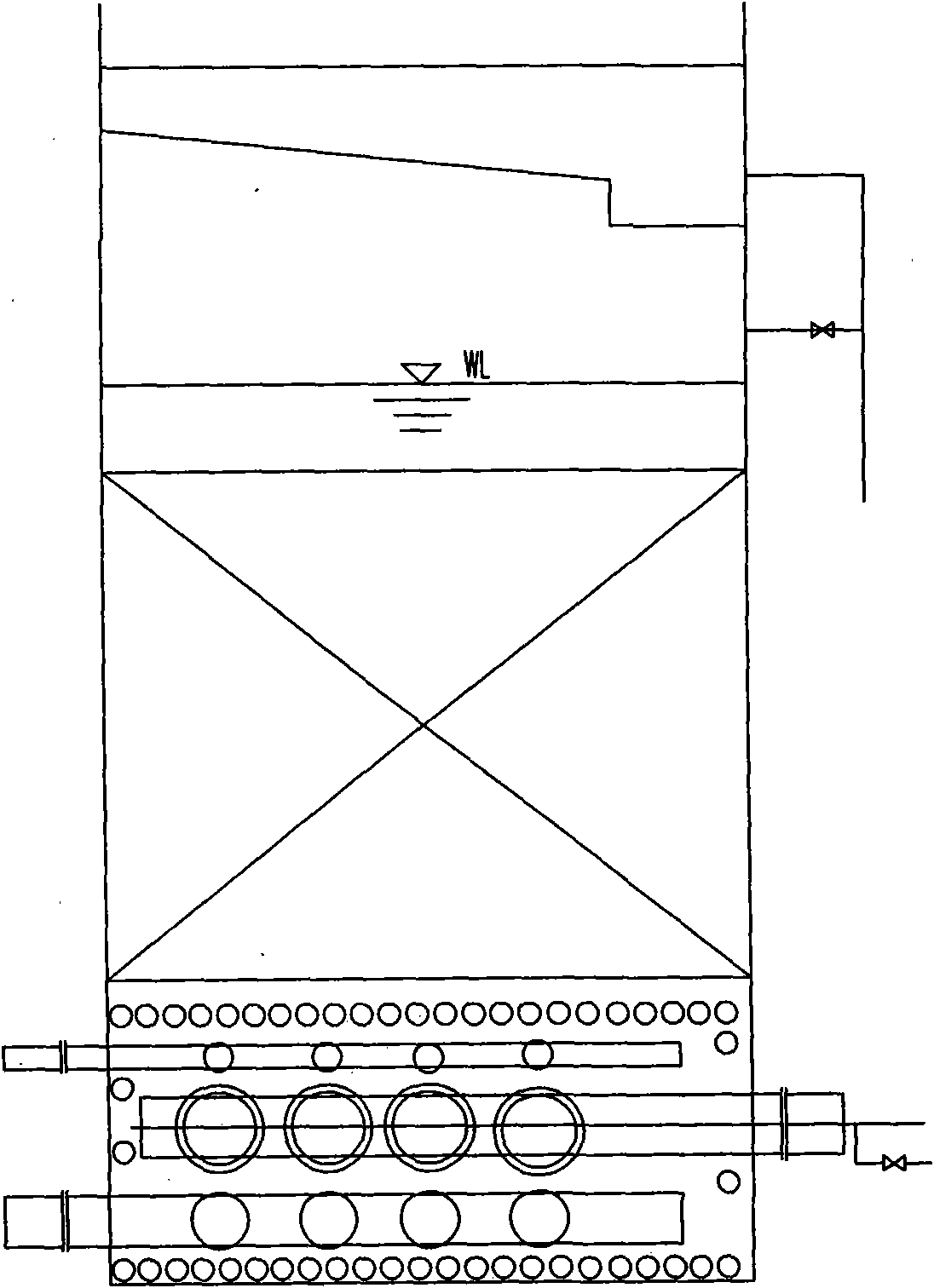

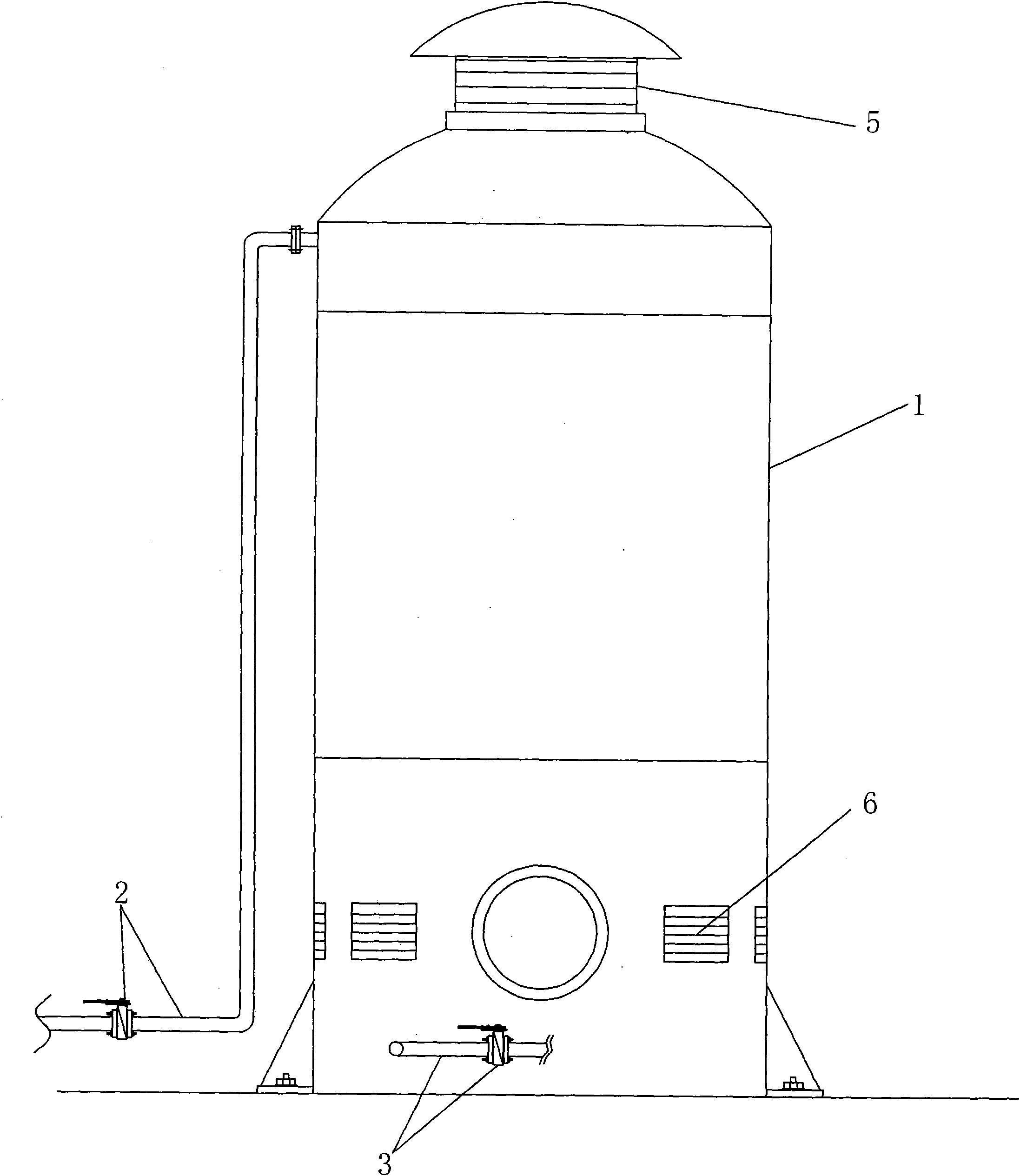

[0021] The non-powered biological filter tower of the present embodiment, as image 3 and Figure 4 As shown, it includes a tower body 1, a water inlet pipe 2 and an outlet pipe 3 respectively arranged on the upper and lower parts of the tower body 1, a water distributor 4 arranged on the upper part of the tower body 1 and connected to the water inlet pipe 2, and filled in the tower body 1. Inside and located at the filter material layer below the water distributor 4. A wind cap 5 is arranged on the top of the tower body 1, and an air inlet 6 is opened on the side wall of the lower part of the tower body. The air inlet 6 adopts shutters. The water distributor 4 has a built-in spin nozzle. The tower body 1 is processed into three sections by steel plates and connected by flanges; the inner wall of the tower body 1 is lined with glass fiber; the outer wall of the tower body 1 is painted with two coats of anti-corrosion paint and sprayed with metal topcoat.

[0022] like Fi...

Embodiment 2

[0025] The unpowered biological filter tower structure of the present embodiment is basically the same as the unpowered biological filter tower in Embodiment 1, the difference is: as Figure 7 As shown, the inclined tube 8 of the elastic filter material layer is replaced by an inclined plate 14.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com