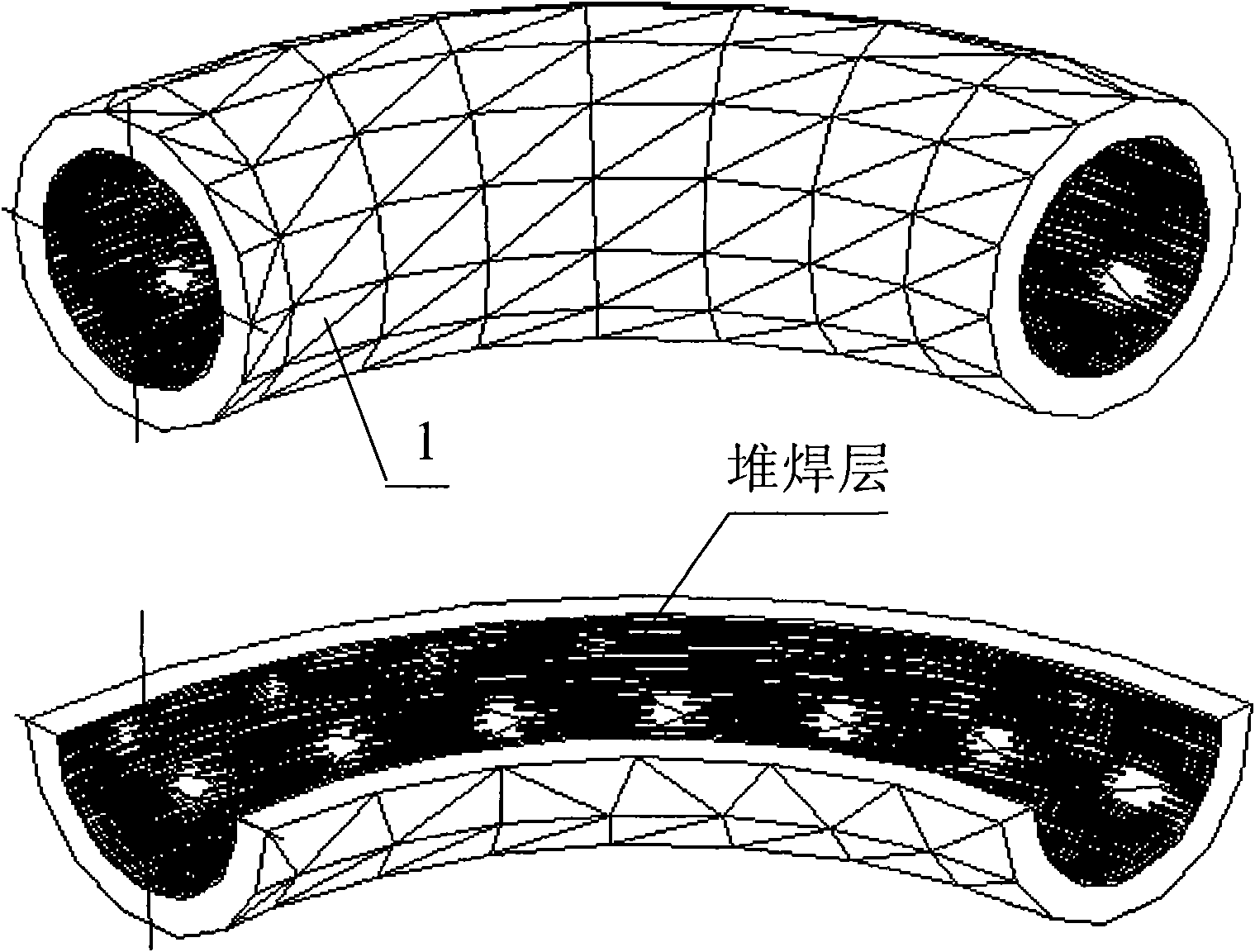

Automatic surfacing device of inner wall anticorrosion layer of 90-degree bent pipe and automatic surfacing method thereof

An automatic surfacing and corrosion-resistant layer technology, applied in welding equipment, tubular objects, arc welding equipment, etc., can solve the problem of long production cycle, inability to achieve overall surfacing of the inner wall of a 90° elbow, and difficult surfacing and welding quality. Guarantee, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

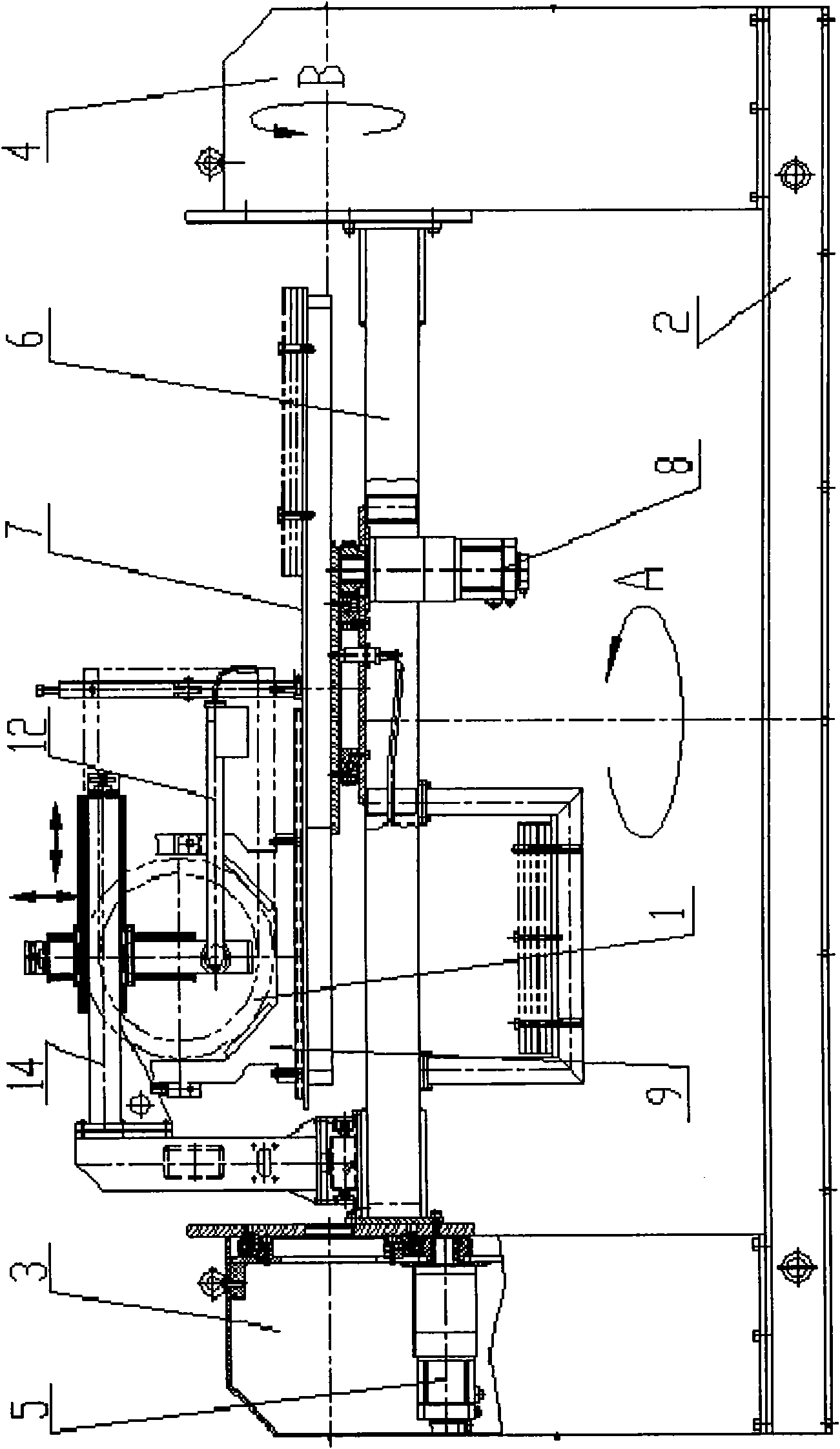

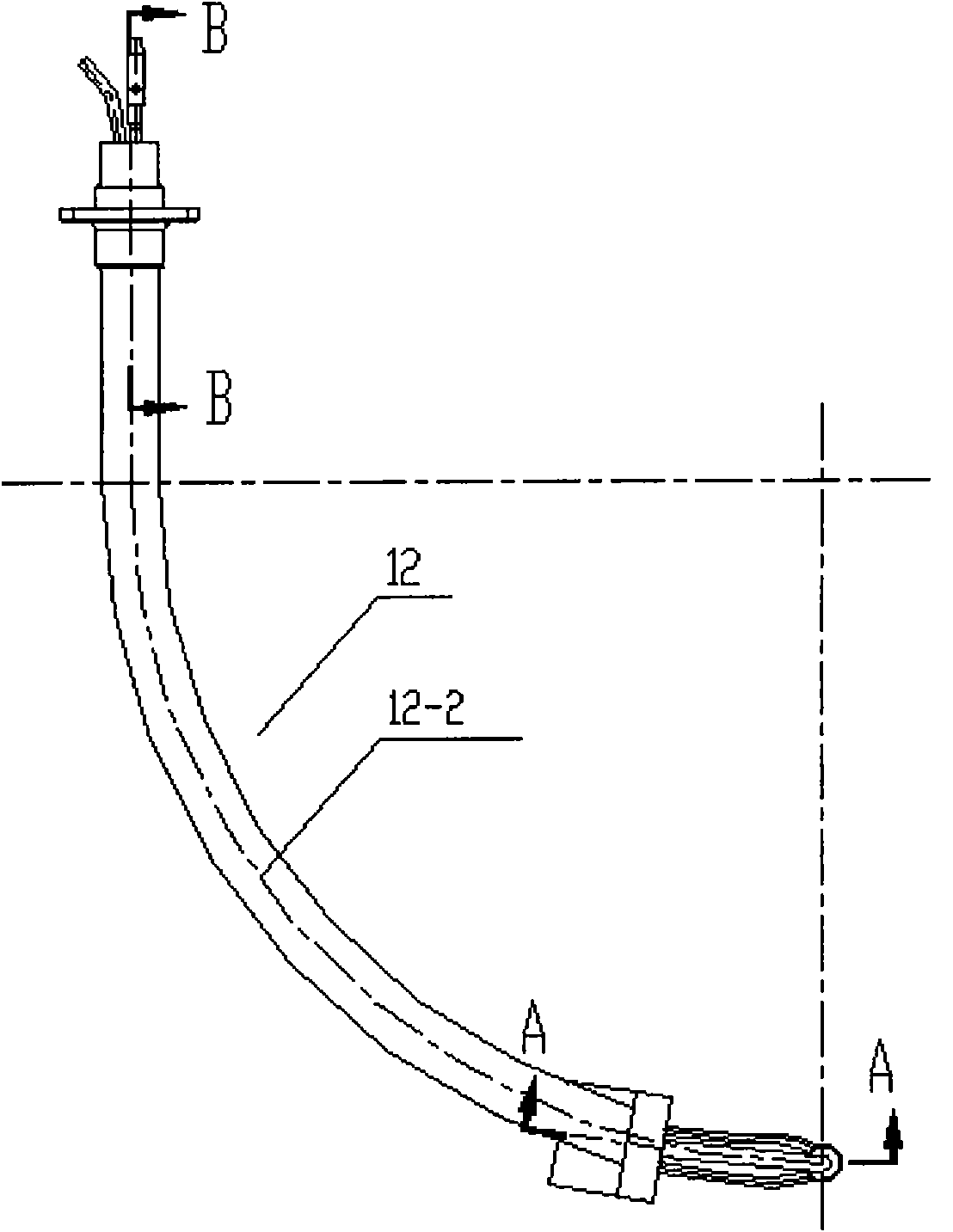

[0045] The surfacing welding of the corrosion-resistant layer on the inner wall of the 90-degree elbow is completed by using the automatic surfacing device for the corrosion-resistant layer on the inner wall of the 90-degree elbow and the automatic surfacing method thereof proposed by the present invention.

[0046] First, the 90° elbow 1 is placed on the turntable 7 by means of three sets of opening and closing fixtures 9, 10, 11. According to the different inner diameter d and curvature radius R of the 90° elbow 1, the three sets of opening and closing fixtures 9, 10, 11 are Slide on the three fixture slides 9-1, 10-1, 11-1 to be adjusted to a suitable size, then turn over the three movable parts 9-4, 10-4, 11-4 with the fixed part 9-2 , 10-2, and 11-2 are closed, so that the 90° elbow 1 is firmly installed on the turntable 7, so that the 90° elbow 1 can be turned over with the turntable 7.

[0047] Turn the turntable 7 and the 90° elbow 1 over to the 0° position of horizont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com