Thickness control compensation method of strip steel head part when welding line passes through rack

A technology of thickness control and compensation method, which is applied in the field of roll calibration for empty roll gaps, and can solve problems such as strip breakage in rolling mills, inability to completely eliminate roll depression tilt, and piled steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

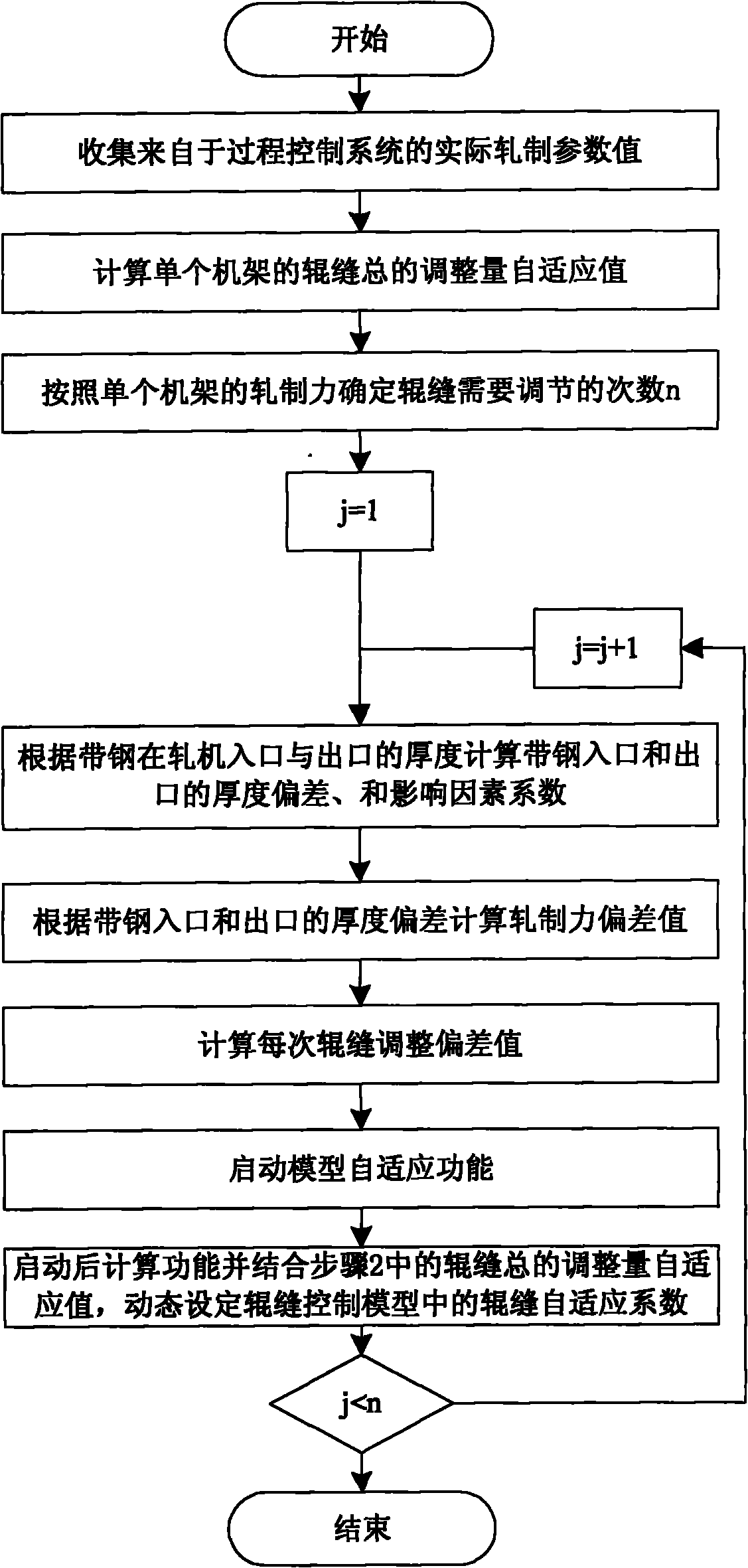

[0057] Attached below Figure 1-5 A preferred embodiment of the present invention will be introduced in detail.

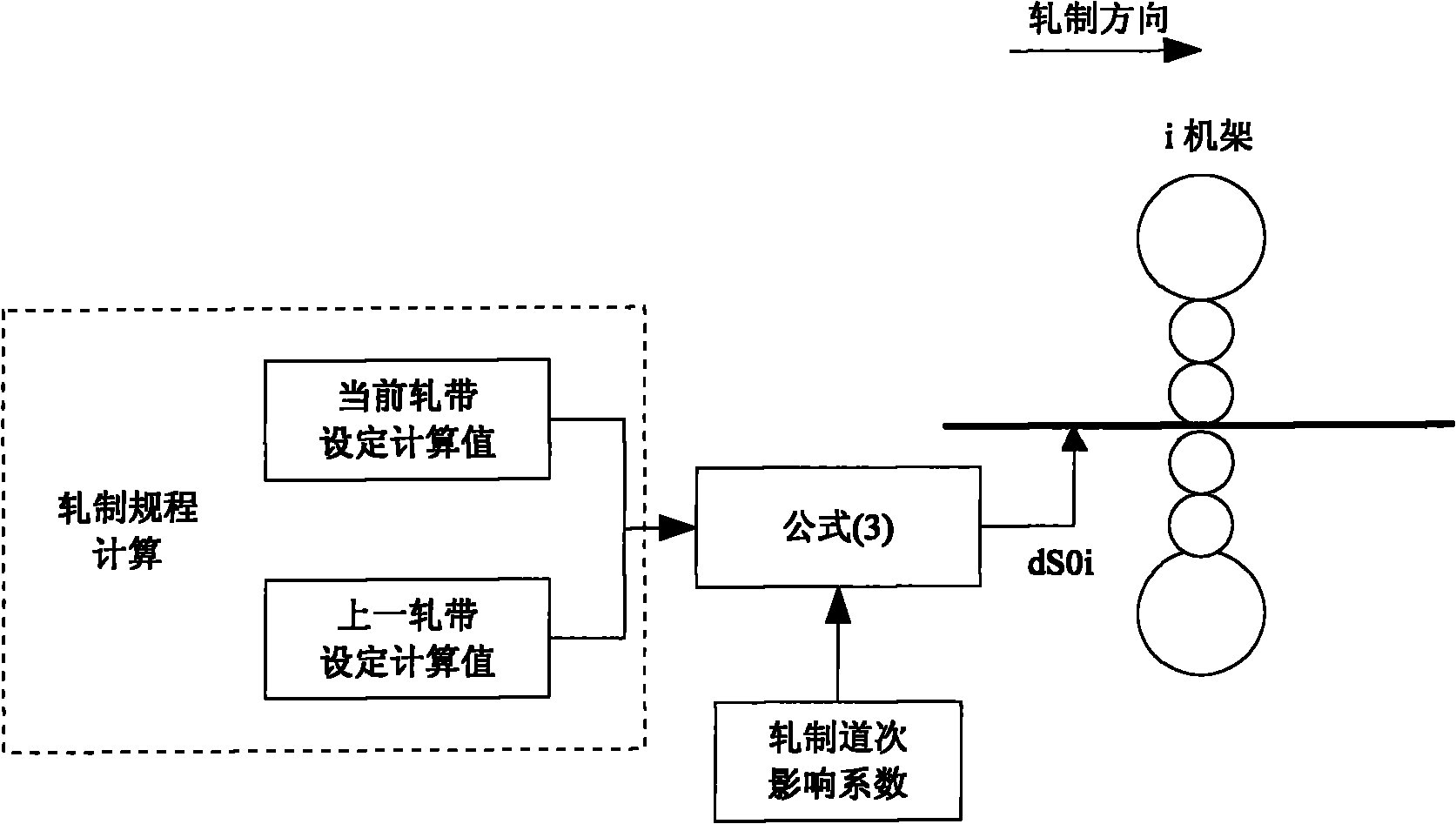

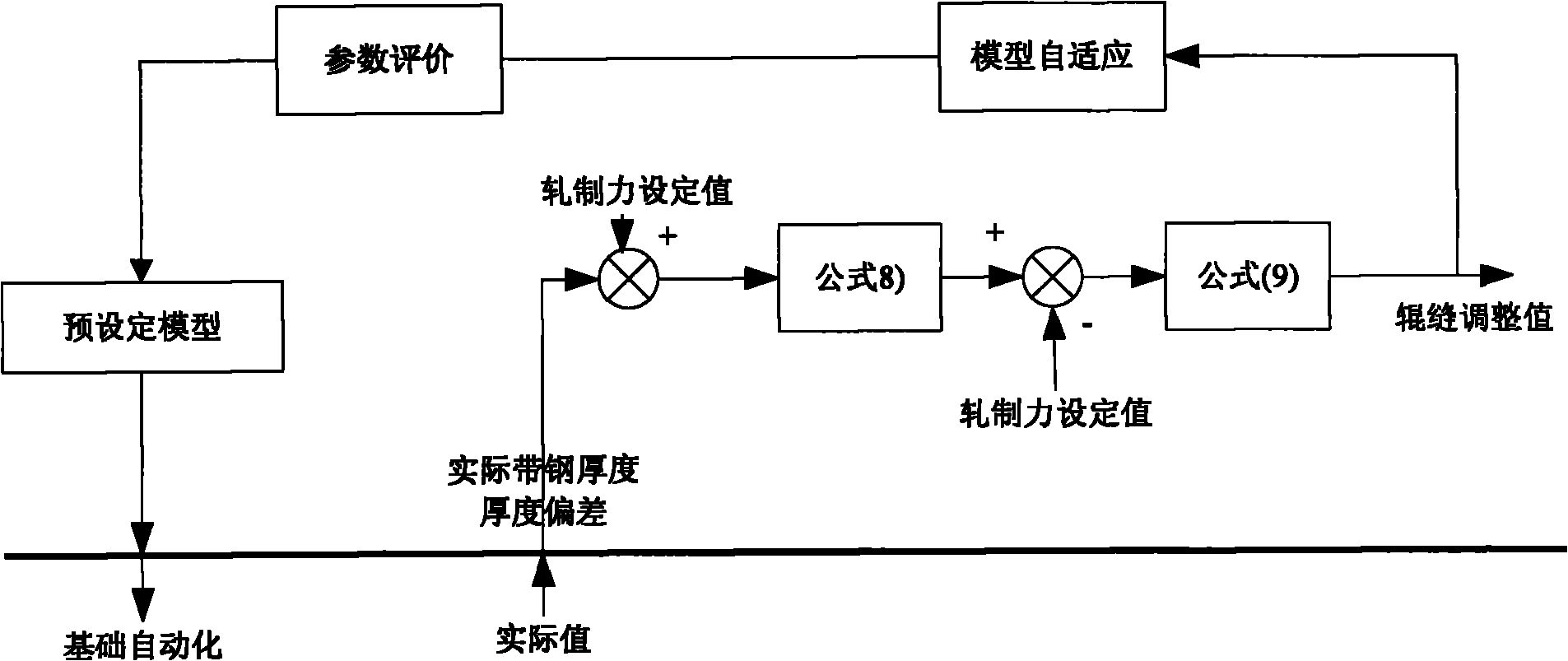

[0058] like Figure 1-3 As shown, a method for controlling and compensating the thickness of the strip steel head when a weld seam passes through a frame of the present invention comprises the following steps:

[0059] Step 1. Collect the actual rolling parameter values from the process control system according to each cycle, including: P rolling force, KN; h strip thickness, mm; total tension, unit KN / mm 2 ;Strip speed;Roll gap height. If conditions permit, the roll gaps on the operating side and the driving side can be collected separately. Using these actual parameters, the model can calculate the roll gap, and analyze and compare with the model pre-calculated results and actual measurement results, so as to further optimize the preset in the future. Determine the precision of the calculation.

[0060] Step 2. When the weld seam passes through the stand, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com