Production process for porcelain doll

A manufacturing process and ceramic technology, applied in the field of ceramics, can solve the problems of unsatisfactory, inability to move the head and hands and feet, and the color of the head is not realistic enough, etc., to achieve the effect of slight wear and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

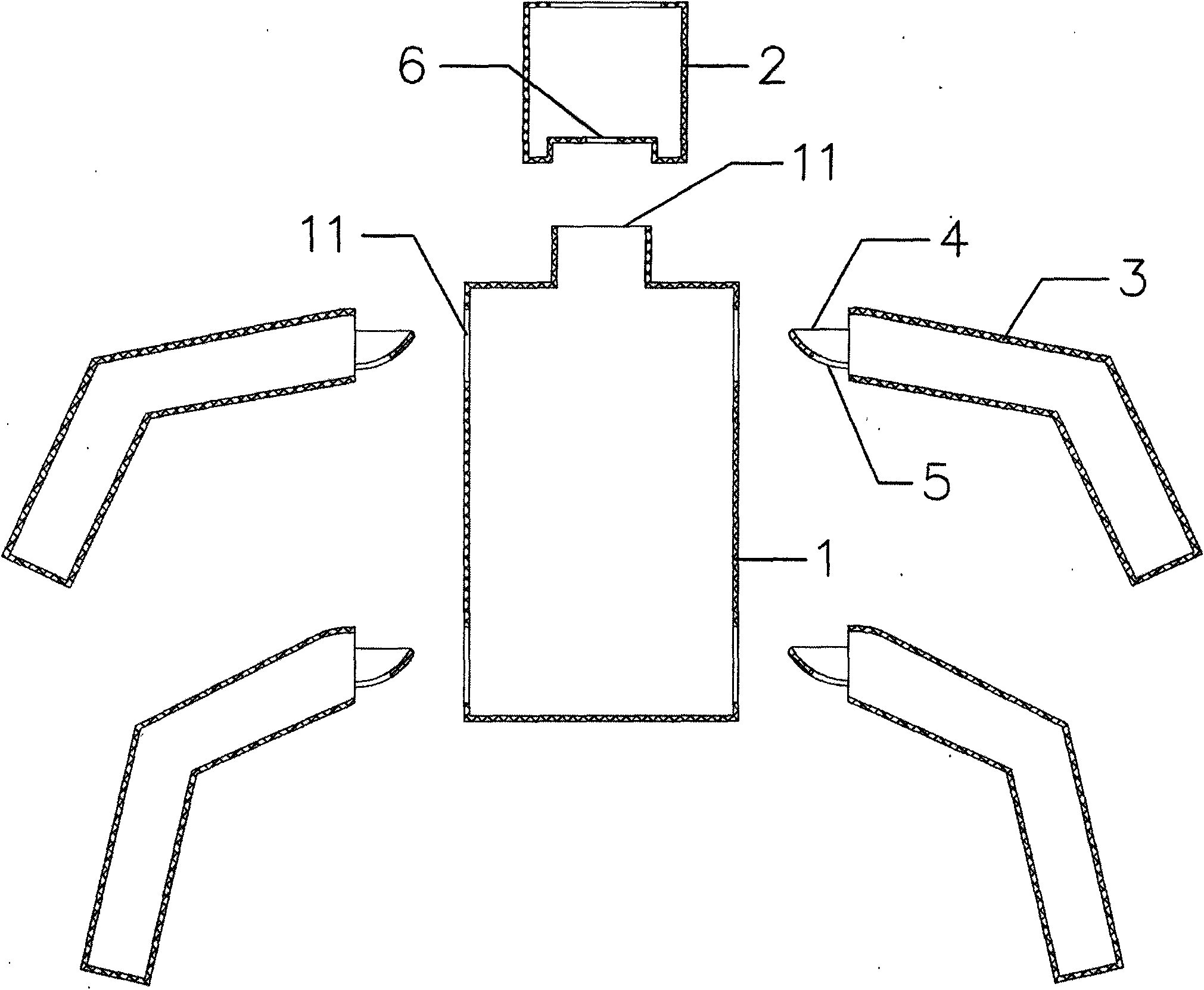

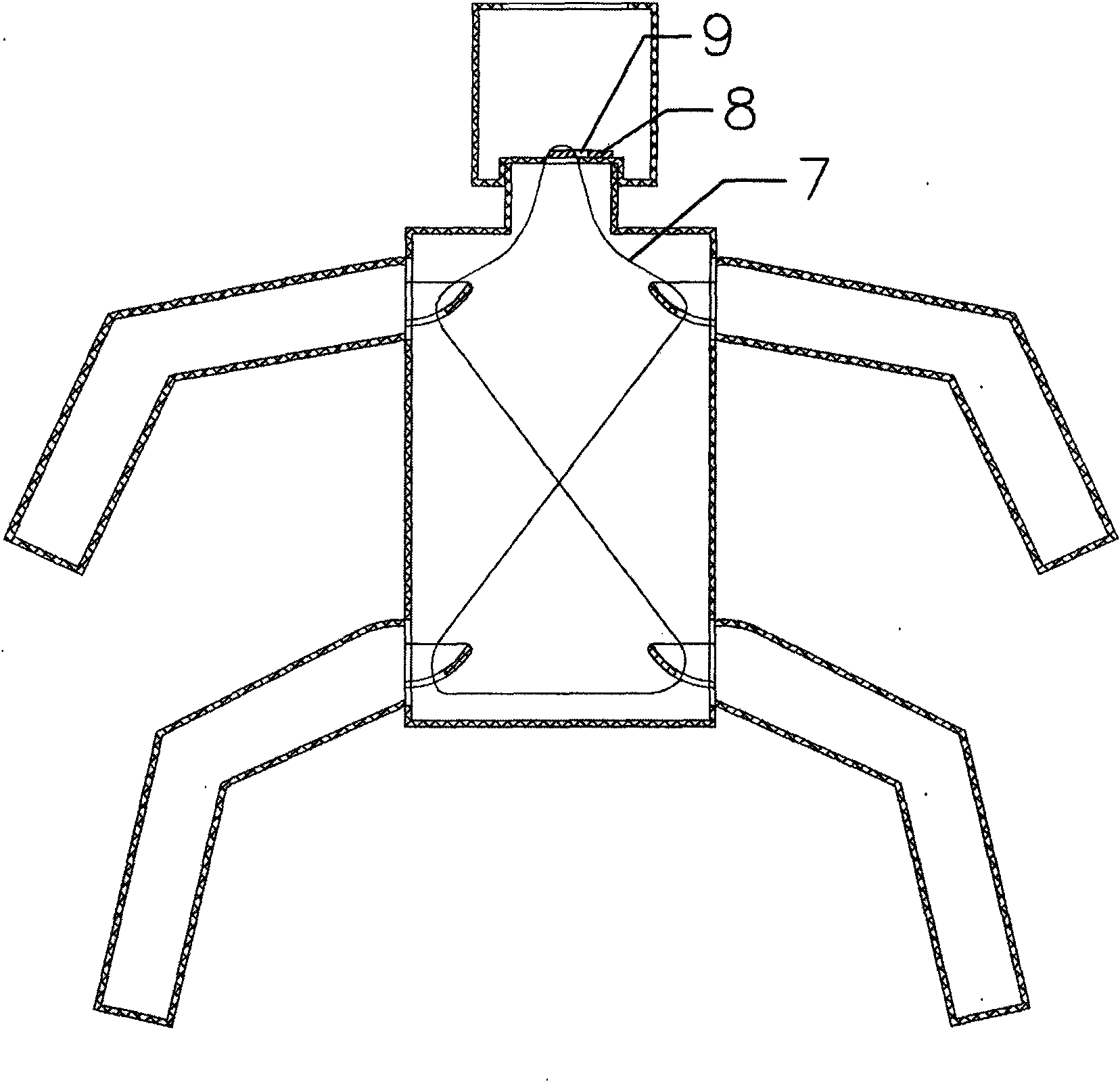

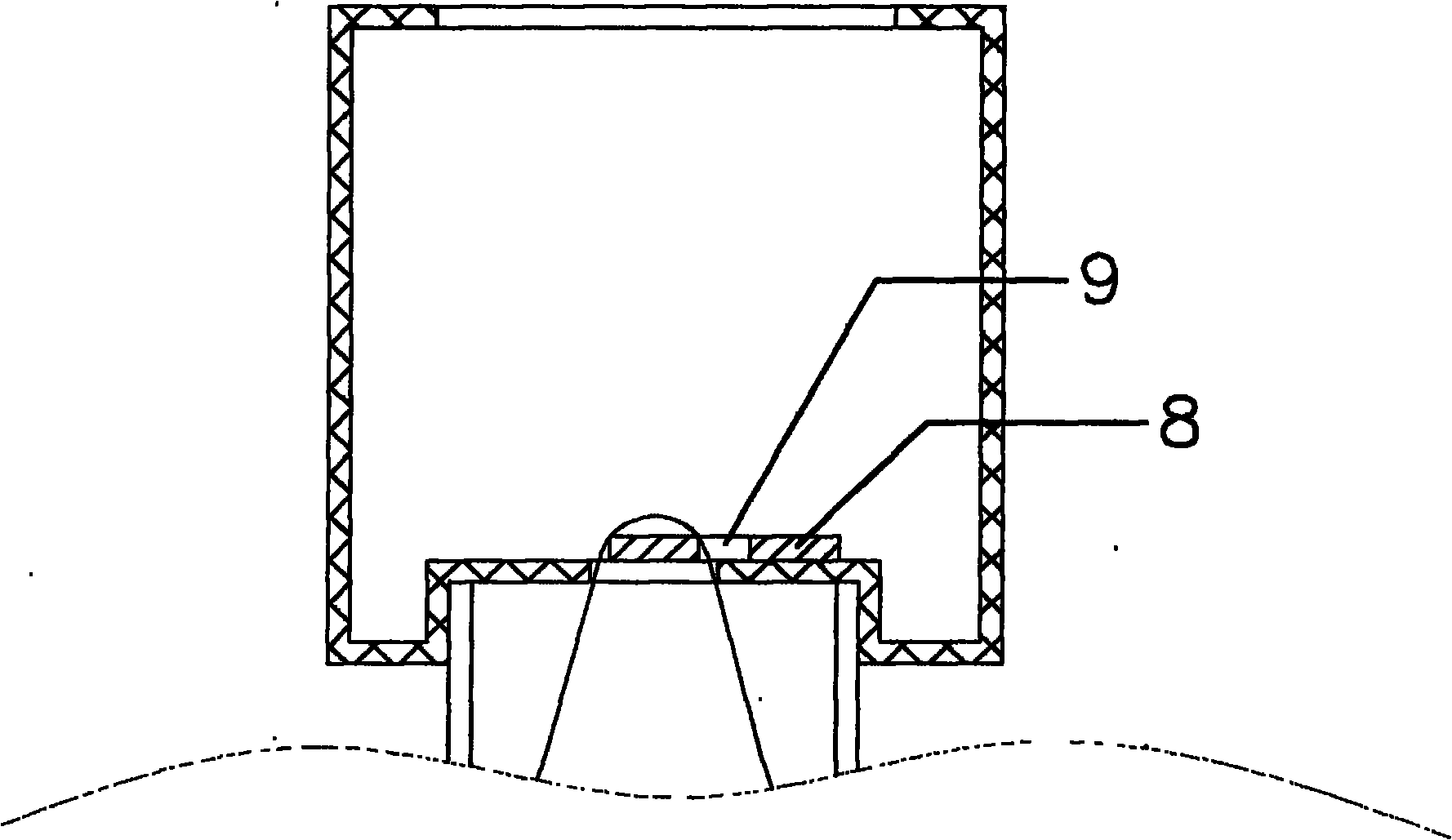

[0022] Example: such as Figure 1~4 Shown, the manufacturing process of ceramic doll of the present invention comprises the following production steps:

[0023] (1) After mixing 20% of iron-containing quartz, 30% of talc and 50% of ashes according to the weight percentage, then add clear water accounting for 30% of the weight of the mixed raw materials, put it into a ball mill for ball milling to a fineness of 320 mesh, and make a color-based material spare;

[0024] (2) Mix 80% of the conventional ceramic mud and 20% of the color-based material by weight percentage, then add clear water accounting for 30% of the weight of the mixed mud, stir and mix to form ceramic mud for subsequent use;

[0025] (3) Design the carcass of the ceramic doll according to the following structure:

[0026] ——The carcass includes detachable torso 1, head 2 and limbs 3;

[0027] ——The torso 1 has a connecting port 11 on the connecting part with the head 2 and the limbs 3, and the corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com