Paper cutting device of paper cutter

A technology of a paper cutting device and a paper cutting machine, which is applied in the direction of metal processing, etc., can solve the problems of easy occurrence of burrs and entanglements in paper cutting, short service life, and easy wear and tear of paper cutting devices, so as to eliminate the burrs and entanglement of paper cutting, Slight wear and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Description with reference to the accompanying drawings.

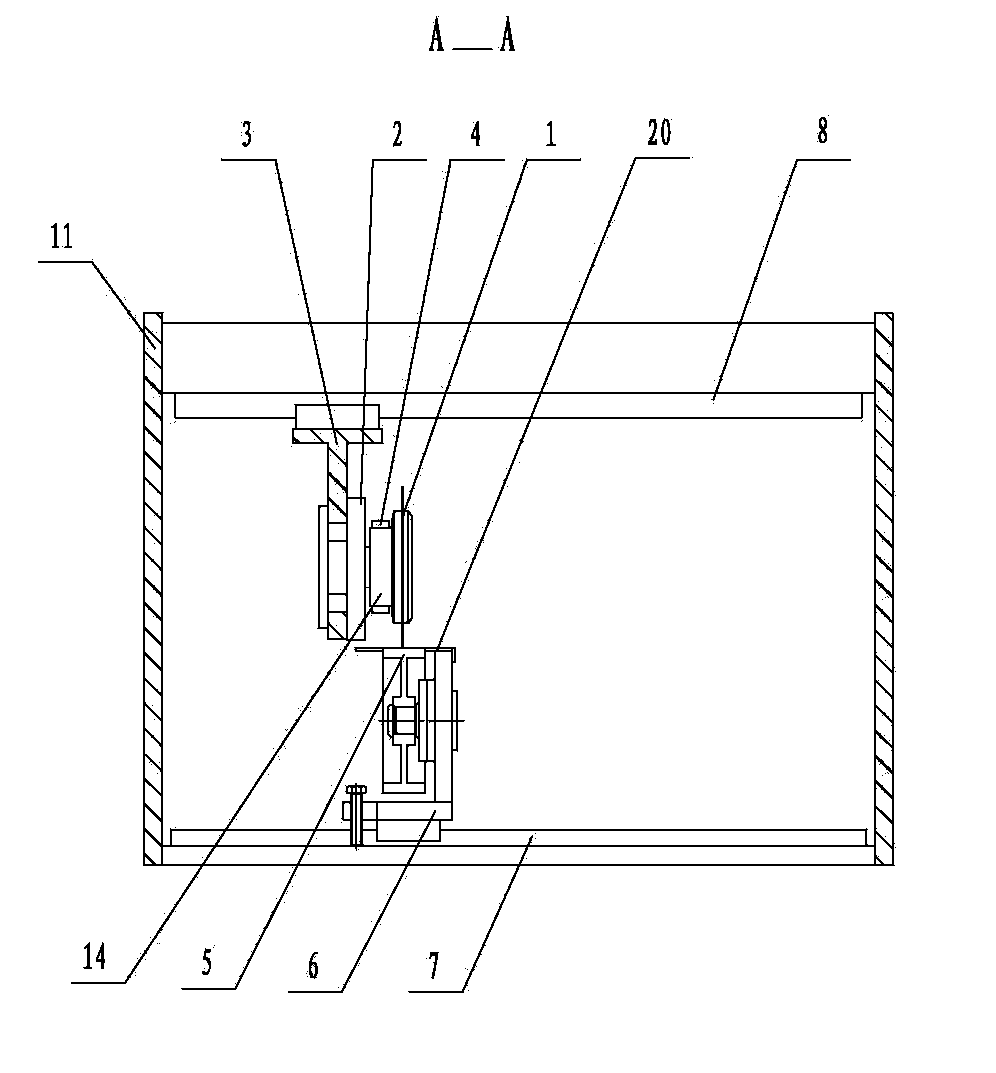

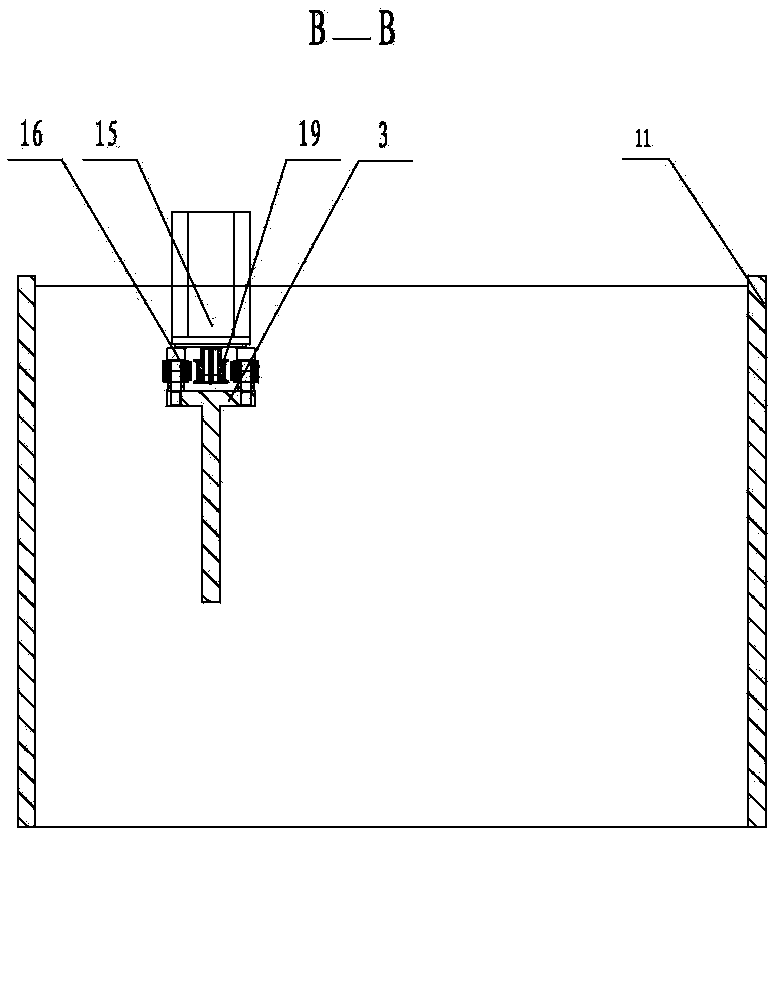

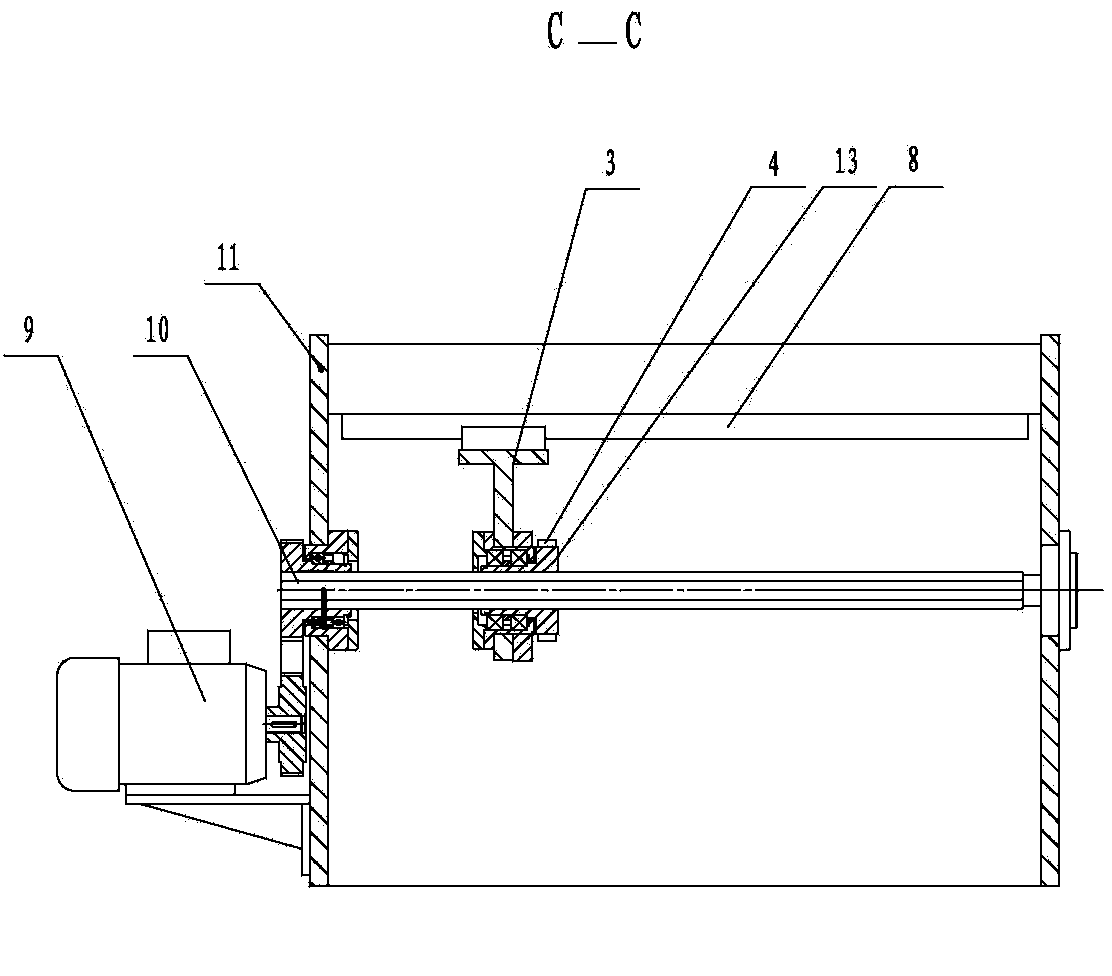

[0021] The paper cutting device frame body of the illustrated embodiment includes left and right vertical wallboards 11 and a bottom surface. The wallboards 11 on both sides are parallel to each other. The upper part between them is equipped with an upper knife linear guide rail 8, and the upper knife linear guide rail 8 is perpendicular to the wall panel 11. , the rubber wheel seat linear guide 7 on the bottom surface is parallel to the upper knife linear guide 8, see figure 2 .

[0022] figure 2 and 4 As shown, the upper knife rotates and drives the power to drive the upper knife 1 to rotate. The rotary drive power of the upper knife in this embodiment is the rotary drive motor 9 for the upper knife, and the output power of the rotary drive motor 9 installed on the left wallboard 11 is transmitted to the active synchronous belt for the rotary drive of the upper knife through the synchronous pulley and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com