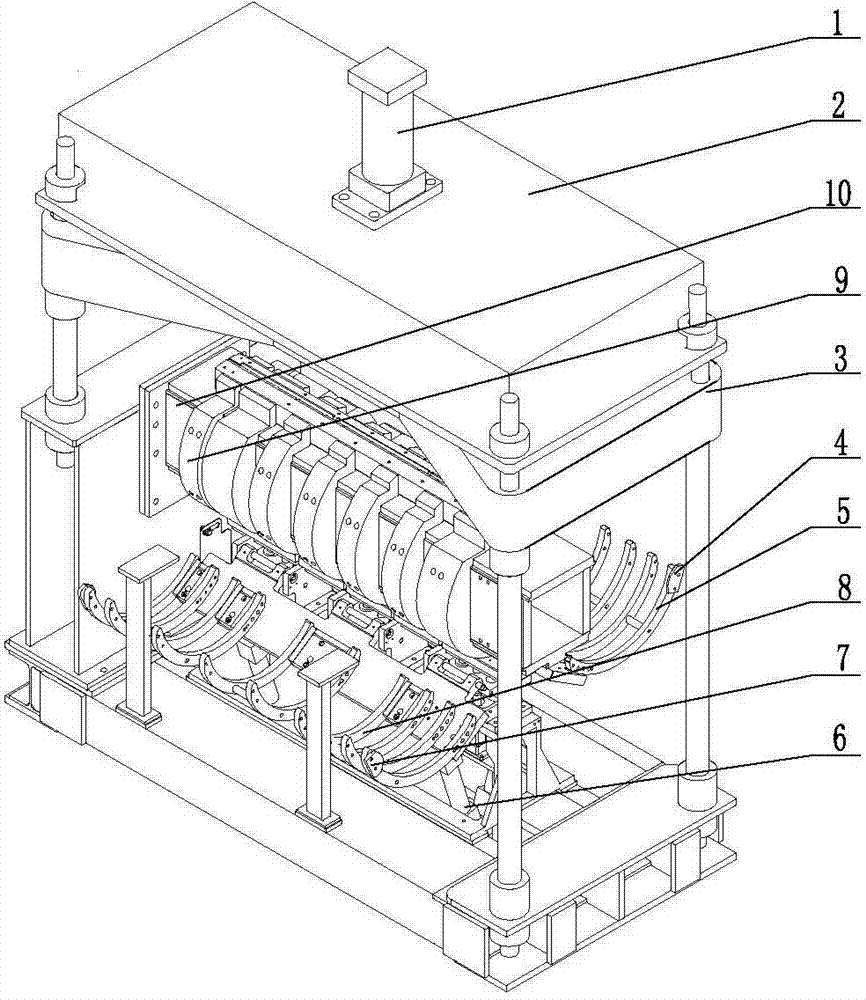

Device for rounding and slotting housing of water heater

A technology for water heaters and shells, which is applied in the field of round seaming devices for water heater shells, can solve the problems of low production efficiency, cumbersome process, and high labor intensity, and achieve the effects of increased production efficiency, simple process, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

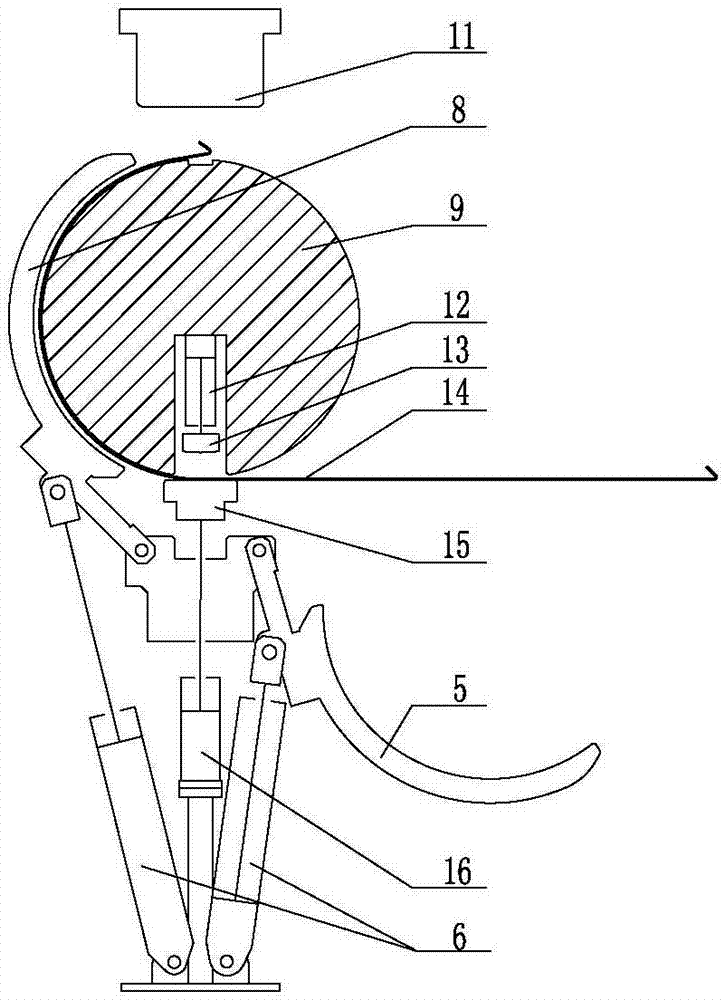

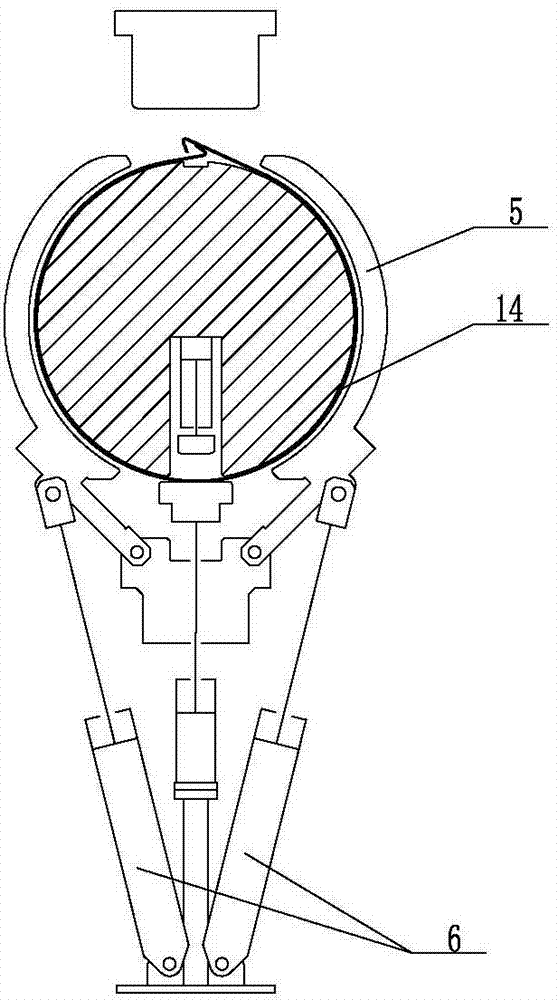

[0020] Description with accompanying drawings. The embodiment shown in the figure is a water storage type electric water heater shell embracing round button seam device, the button seam die power is a press, the cylinder of the middle beam cylinder 1 is fixed on the upper beam 2, and the piston rod drives the middle beam 3 to reciprocate up and down Movement, the buckle die 11 is fixed under the middle beam 3. The left end, that is, the front end of the cantilevered inner mold 9, is fixed on the machine base by the inner mold frame 10, and the right end, that is, the rear end of the inner mold 9, is suspended. The inner mold support cylinder is fixedly installed on the machine base below the right end of the inner mold 9, the piston rod of the cylinder is connected to the inner mold support arm, the plate to be processed 14 is positioned and fed, and when the buckle seam mold 11 and the inner mold 9 are aligned, The inner mold support arm rises to support the rear end of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com