Stop valve centrifugal pump device

A technology of centrifugal pumps and stop valves, which is applied to components, pumps, and driving pumps of elastic fluid pumping devices, and can solve the problems of polluting the surrounding environment of machine pumps, wear, and large vibrations of centrifugal pumps, and achieves improved labor efficiency. Conditions, Simplified Piping System, Minor Effect of Wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific examples.

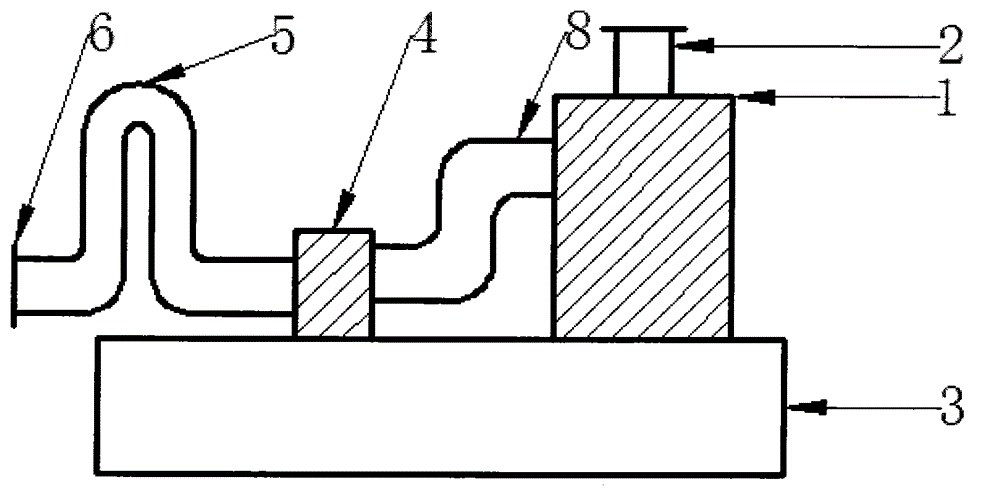

[0014] Such as figure 1 Shown: the shut-off valve centrifugal pump device is composed of an electric valve (4), a centrifugal pump (1), a support (3), an S-shaped pipeline (8) and a U-shaped pipeline (5).

[0015] The connection of the centrifugal pump (1) and the electric valve (4) is fixed by pipeline connection; the centrifugal pump (1) and the electric valve (4) are installed on the support (3); the centrifugal pump (1) and the electric valve (4) ) start and stop are synchronous.

[0016] The electric valve (4) is an electric ball valve.

[0017] The metal material of the bracket (3) is angle steel.

[0018] The electric valve (4) is installed in the middle of the S-shaped pipeline (8) and the U-shaped pipeline (5); the pipeline fixedly connected to one end of the electric valve (4) and the centrifugal pump (1) is the S-shaped pipeline (8); the electric valve The pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com