Polyurethane water vapor seal zipper and preparation method thereof

A sealing zipper and polyurethane technology, which is applied in the field of zippers, can solve the problems of being easily corroded by oil stains, small application range, and short service life, and achieves the effects of not being easily corroded by oil stains, good sealing effect, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in further detail below in conjunction with accompanying drawing:

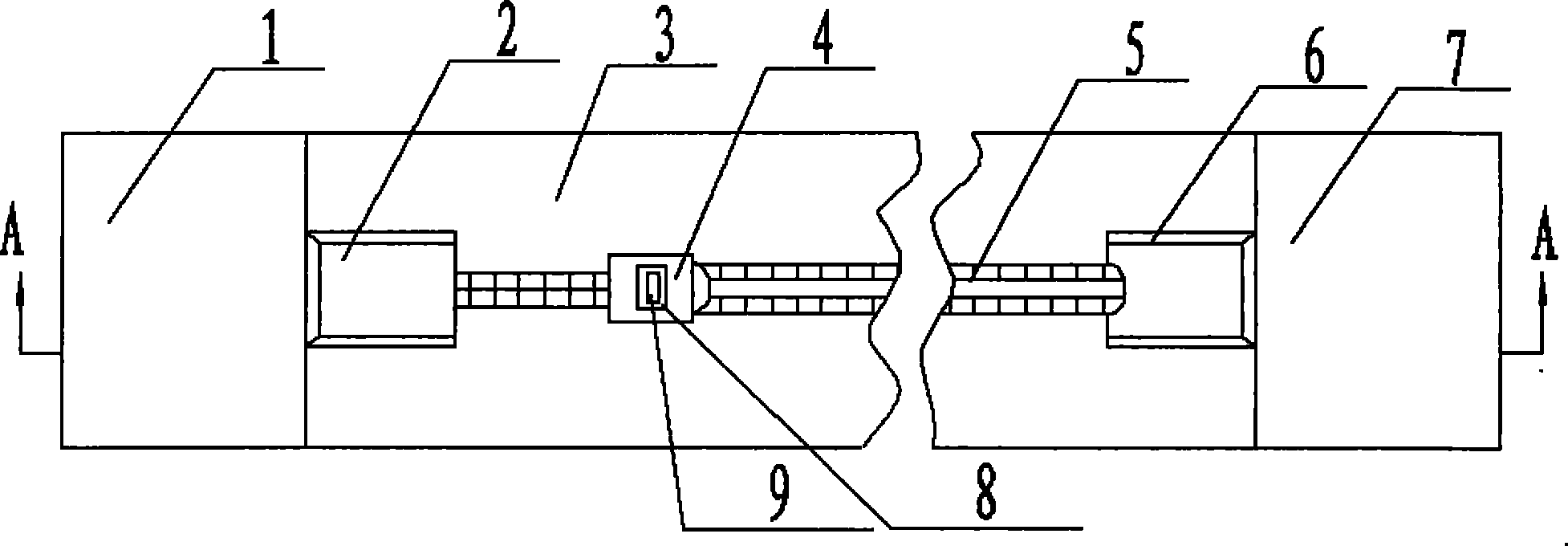

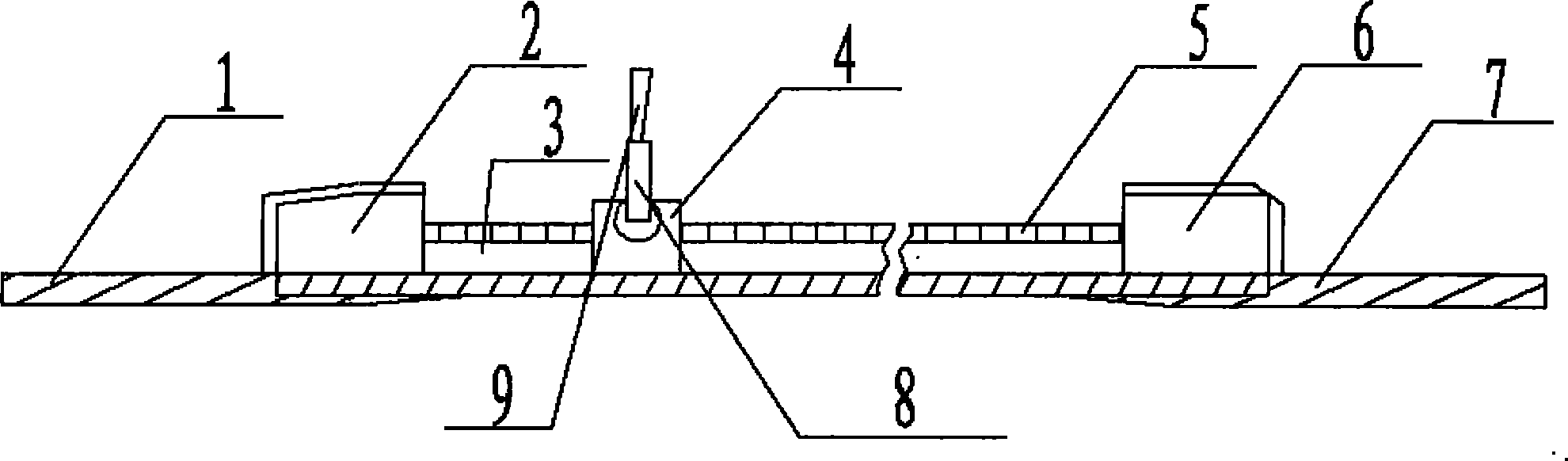

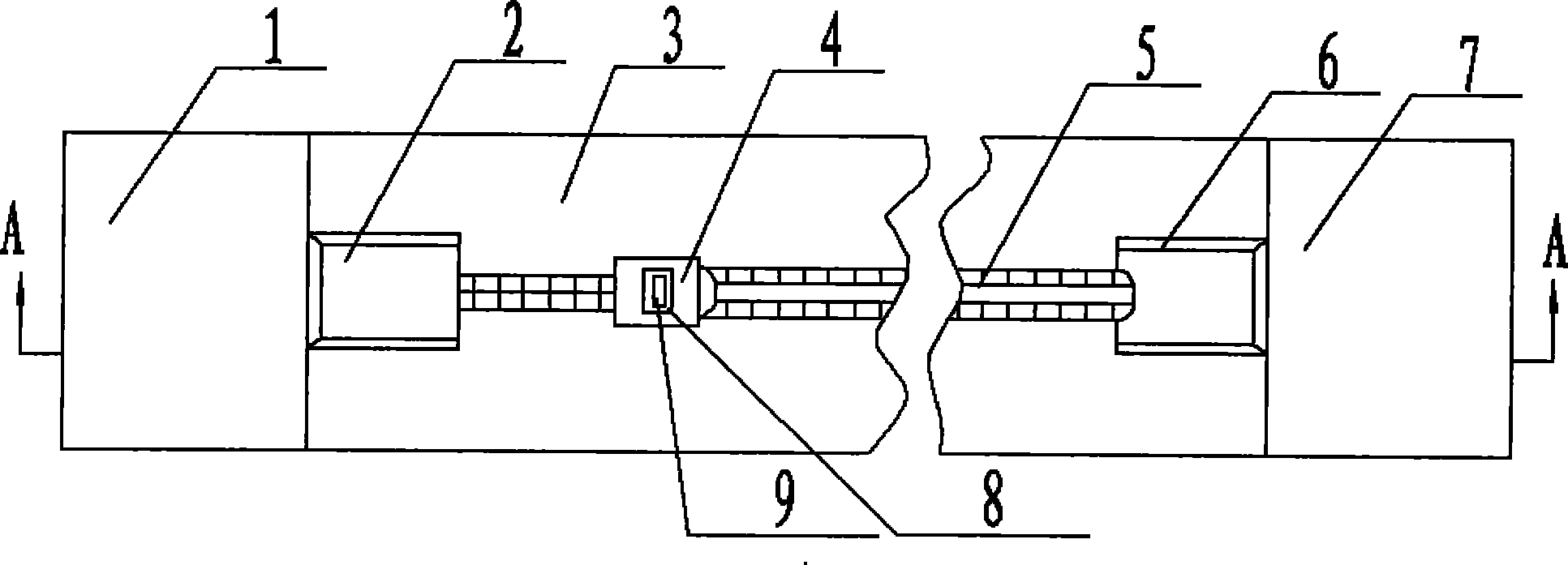

[0018] see figure 1 , 2 , a polyurethane moisture-tight zipper, comprising a polyurethane base cloth 3, a chain 5, a slider 4, an upper stop 2, a lower stop 6, an upper end cap 1 and a lower end end 7; the chain 5 is fixed on the polyurethane base cloth 3 The upper chain teeth are coupled to each other; the upper end of the chain 5 and the upper stop 2 are fixed on the upper head 1 by injection molding; the lower end of the chain 5 and the lower stop 6 are fixed on the lower head 7 by injection molding; A slider 4 is arranged on the chain 5 .

[0019] The polyurethane base cloth 3 is a high-strength polyester or nylon chemical fiber cloth, and the thickness of the polyurethane base cloth 3 is 2.3mm, 3mm or 3.9mm.

[0020] The upper surface of the polyurethane base cloth 3 is provided with a polyurethane film with a thickness of 0.05 mm, 0.1 mm, 0.6 mm or 0.8 mm; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com