Drying tower with positive-negative shunt structures and drying method thereof

A drying tower, tower-type drying technology, applied in the fields of application, food preparation, food science, etc., to achieve the effect of avoiding particle adhesion and avoiding uneven drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] A drying tower comprising the following parts:

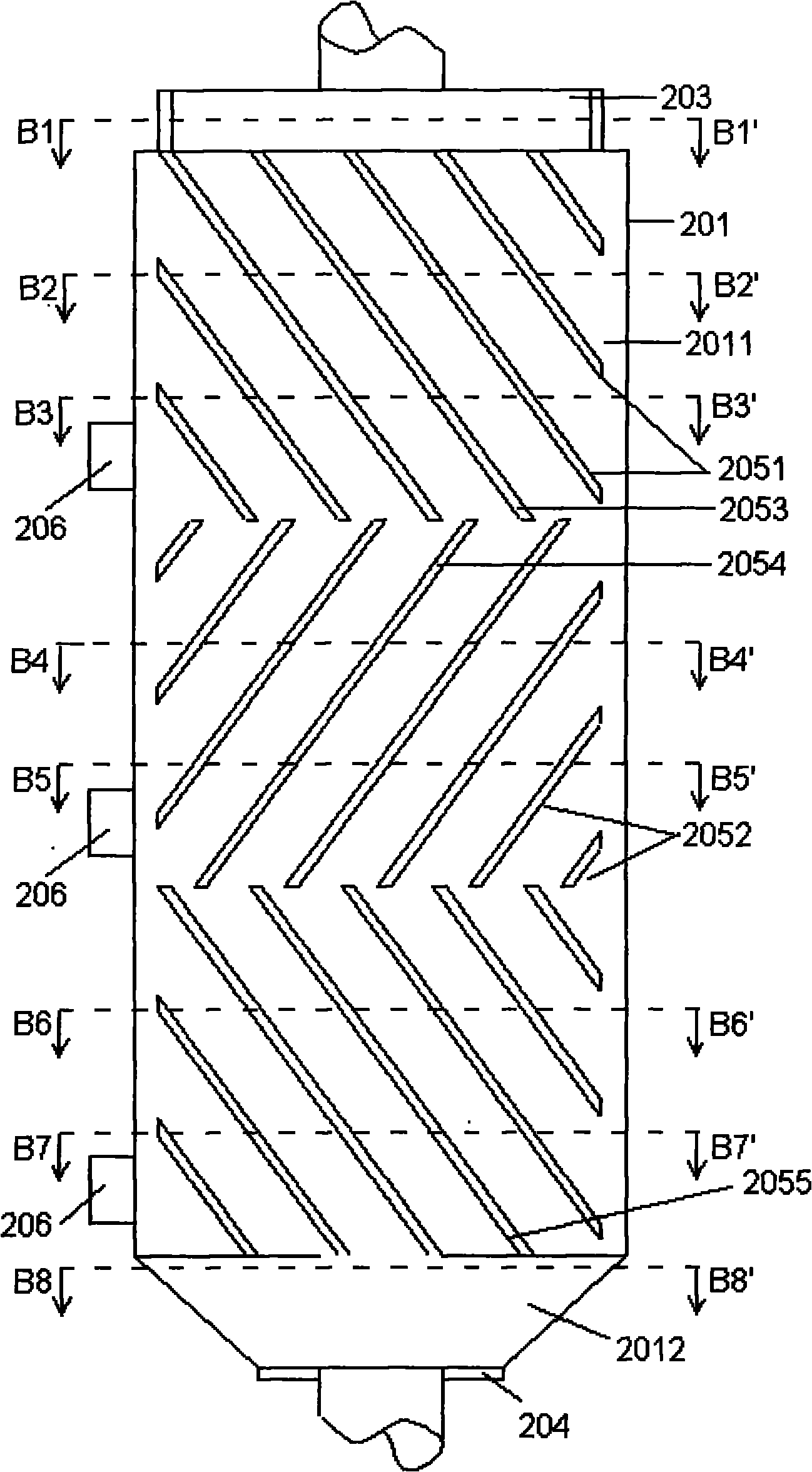

[0080] according to figure 1 :

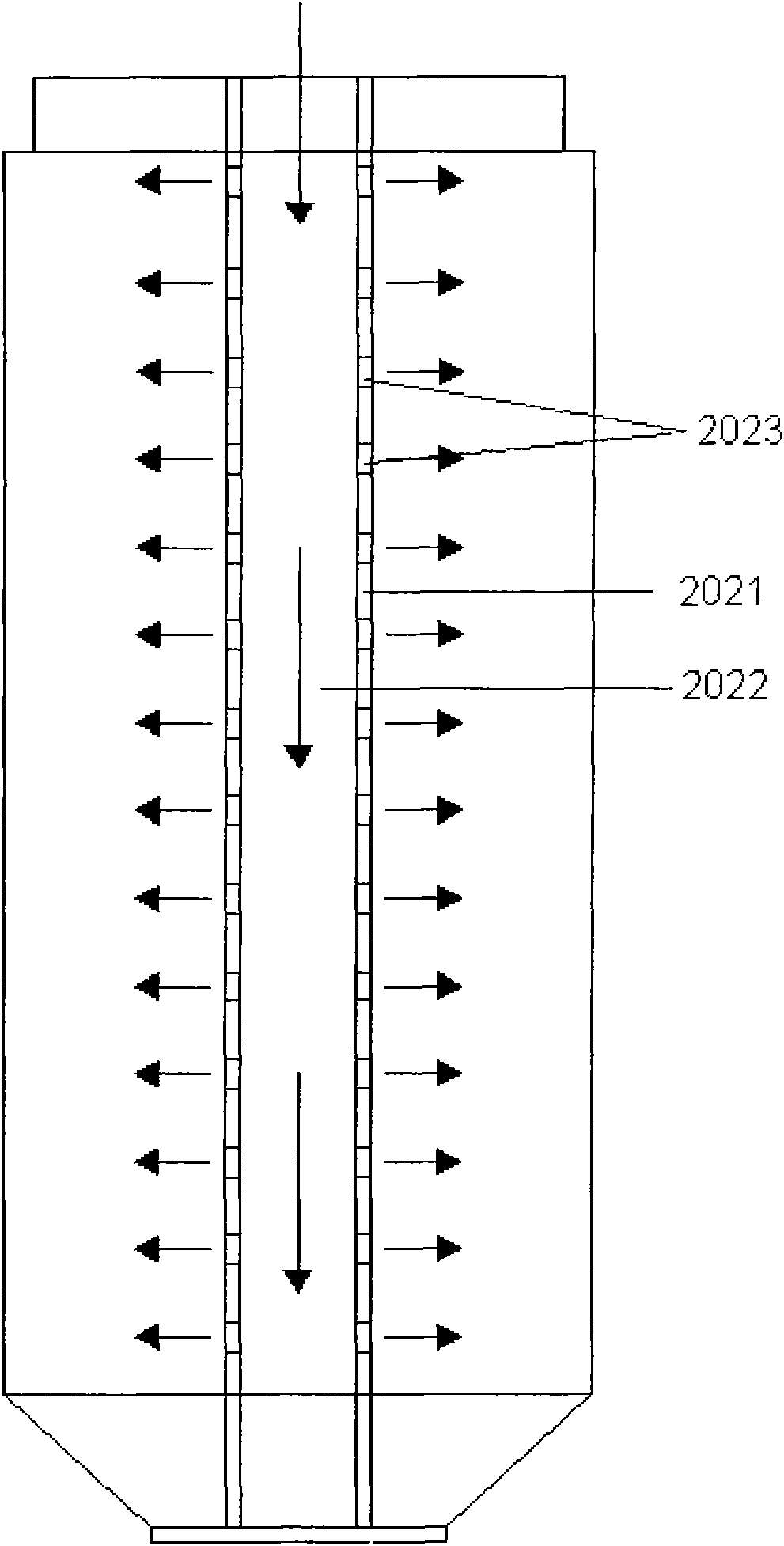

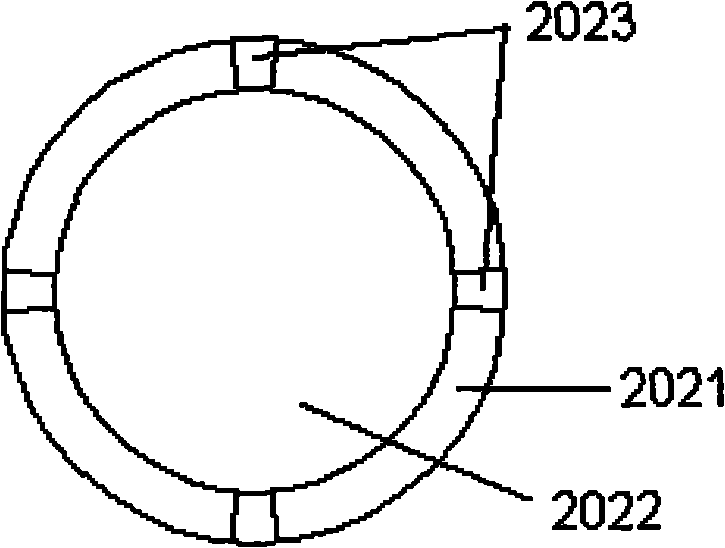

[0081] A drying tower, comprising a shell 201 , a rotating shaft 202 , a material inlet 203 , a material outlet 204 , and a flow distribution channel 205 .

[0082] The casing 201 includes a cylindrical tower drying chamber 2011 at the upper part and a conical storage chamber 2012 at the lower part.

[0083] according to figure 1 :

[0084] The distribution material channel 205 includes a group of distribution structures 2050 rotating around the rotating shaft 202 .

[0085] The distribution material channel 205 includes 2 to 6 distribution structures 2050 , and the distribution structures 2050 are divided into a forward distribution structure 2051 and a reverse distribution structure 2052 . The forward flow distribution structures 2051 and the reverse flow distribution structures 2052 are arranged alternately.

[0086] according to Figure 4a , 4b , 4c, 4d, 4e, 4f:

[0087] The s...

Embodiment 2

[0130] Adopt the following technical parameters to improve embodiment one:

[0131] The distribution material channel 205 includes two distribution structures 2050

[0132] Each shunt structure 2050 includes 4 shunt gates.

[0133] The inclination angle b2 between the forward shunt gate of the forward shunt structure 2051 and the horizontal plane is 135°.

[0134] The inclination angle b3 between the reverse shunt gate of the reverse shunt structure 2052 and the horizontal plane is 45°.

[0135] Wherein the ratio of the distance L1 to L2 between the reverse shunt grid and two adjacent forward shunt grids is 1:1. The ratio of the vertical length of the interlaced area between the reverse shunt grid and the adjacent forward shunt grid to the distance L3 between two adjacent forward shunt grids and L1+L2 is 1:6.

[0136] The angle formed between the air outlet 2063 and the horizontal plane is 42°.

Embodiment 4

[0138] Adopt the following technical parameters to improve embodiment one:

[0139] The distribution material channel 205 includes three distribution structures 2050

[0140] Each shunt structure 2050 includes 8 shunt gates.

[0141] The inclination angle b2 between the forward shunt gate of the forward shunt structure 2051 and the horizontal plane is 129°.

[0142] The inclination angle b3 between the reverse shunt gate of the reverse shunt structure 2052 and the horizontal plane is 51°.

[0143] Wherein the ratio of the distance L1 to L2 between the reverse shunt grid and two adjacent forward shunt grids is 1:1. The ratio of the vertical length of the interlaced area between the reverse shunt grid and the adjacent forward shunt grid to the distance L3 between two adjacent forward shunt grids and L1+L2 is 1:4.

[0144] The angle formed between the air outlet 2063 and the horizontal plane is 48°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com