Anti-sticking grain dicing machine for color masterbatch

A color masterbatch and pelletizer technology, applied in the field of cutting machines, can solve problems such as unfavorable production and color masterbatch adhesion, and achieve the effect of avoiding particle adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

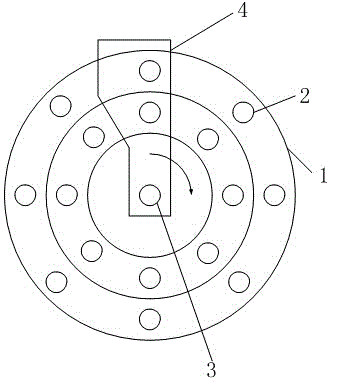

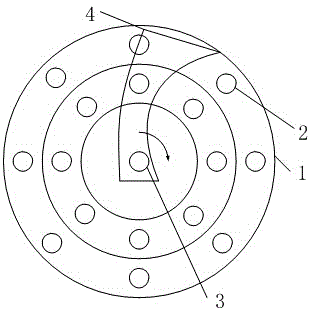

[0013] Such as figure 2 As shown, the present invention discloses an anti-stick pelletizer for color masterbatch, consistent with the prior art, including an extruder head 1, and the center of the extruder head 1 is connected with a pelletizer for cutting through a rotating shaft 3. Blade 4, the extruder head includes inner and outer ring double-ring discharge heads (not shown in the figure), and several discharge ports 2 are evenly distributed on the inner and outer ring discharge heads, and the discharge ports 2. The material is discharged at the same time, and the blade 4 is driven to rotate through the rotation of the rotating shaft 3, so as to cut off the extruded material. The length of masterbatch pellets can be adjusted through the distance between the outlets 2 on the same circle. Other driving and connection structures are all prior art, and will not be repeated here.

[0014] Different from the prior art, in order to prevent the granulated material from sticking,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com