Loudspeaker vibration sound film

A technology of loudspeaker and sound film, applied in the direction of sensor, diaphragm structure, electrical components, etc., can solve the problems of insufficient high frequency extension, insufficient vocal clarity, bulky loudspeaker, etc., and achieve the effect of increasing internal loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is implemented like this:

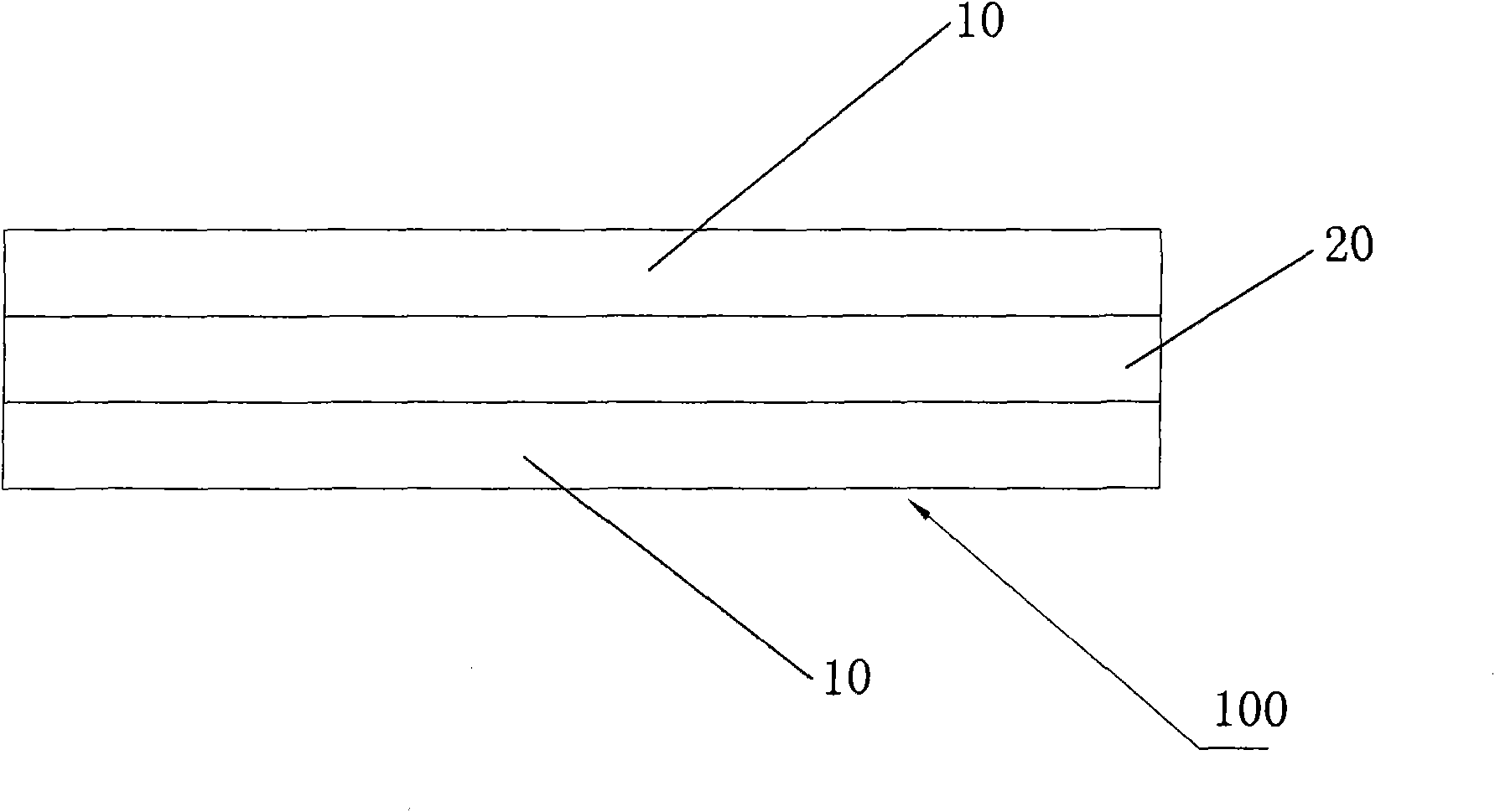

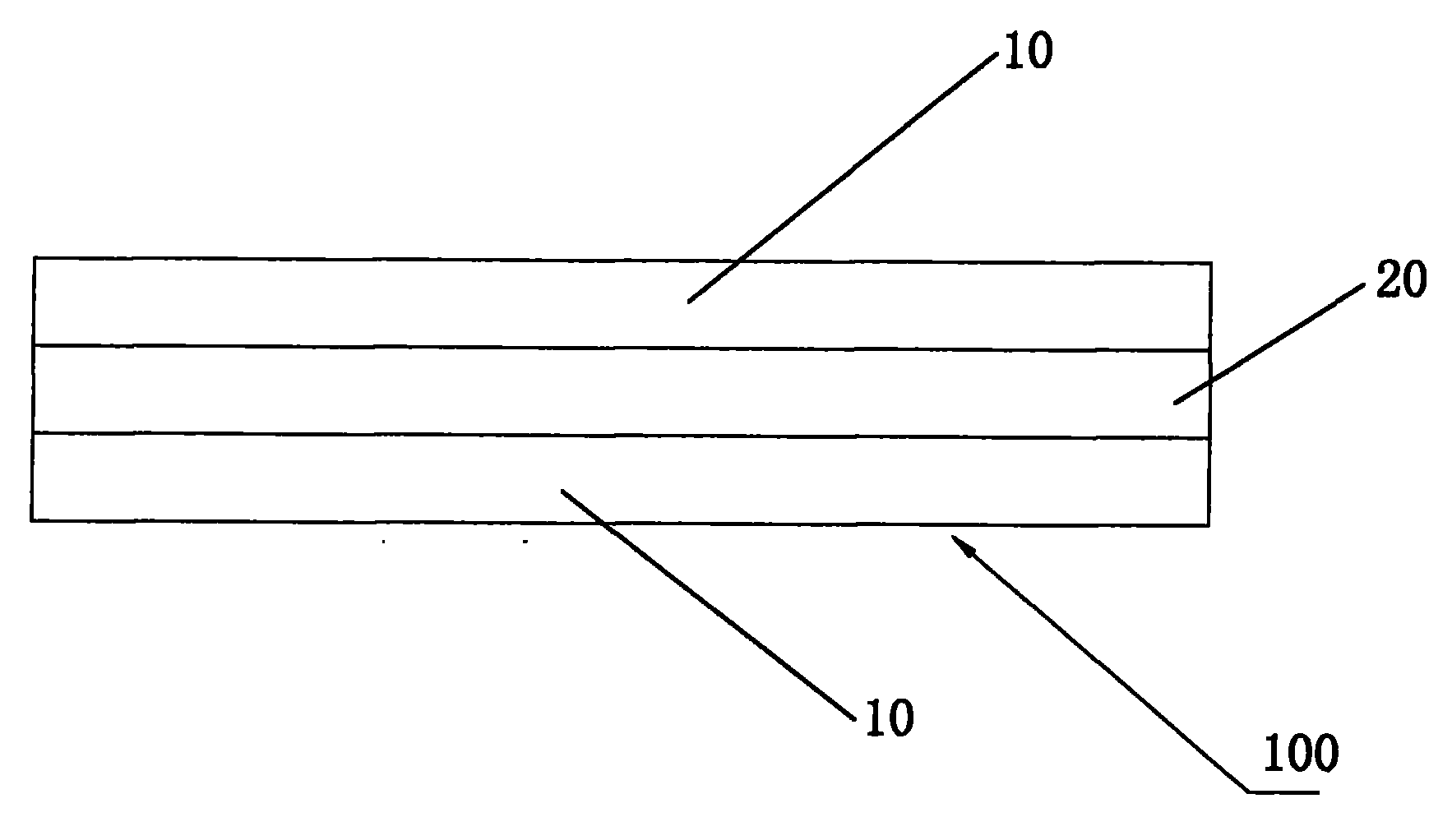

[0024] A loudspeaker vibrating sound membrane is used for a loudspeaker. The sound membrane 100 is composed of a fiber layer 10 , a balsa wood layer 20 and a fiber layer 10 laminated in sequence.

[0025] The fiber layer 10 is carbon fiber cloth, glass fiber cloth, basalt fiber cloth, aramid fiber cloth, paper fiber or chemical fiber.

[0026] The balsa wood layer 20 is made of balsa wood or wood pulp paper.

[0027] The outer surface of the fiber layer 10 is a pure plane or a concave-convex surface.

[0028] The fiber layer 10, the balsa wood layer 20 and the fiber layer 10 are laminated and then thermocompressed.

[0029] A kind of manufacturing process of above-mentioned loudspeaker vibrating sound film, this manufacturing process comprises the following steps:

[0030] 1), firstly, apply hot resin on both surfaces of the balsa wood layer;

[0031] 2), then attach the two fiber layers to the top and bottom surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com