Optical imaging alignment measurement device

A measuring device and optical imaging technology, which is applied in the direction of measuring point marking, etc., can solve problems in the field of missile artillery launch, such as difficulties in launching missiles, accuracy, reliability limitations, and expensive measuring instruments, and achieve easy installation and application, high centering accuracy, The effect of strong reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

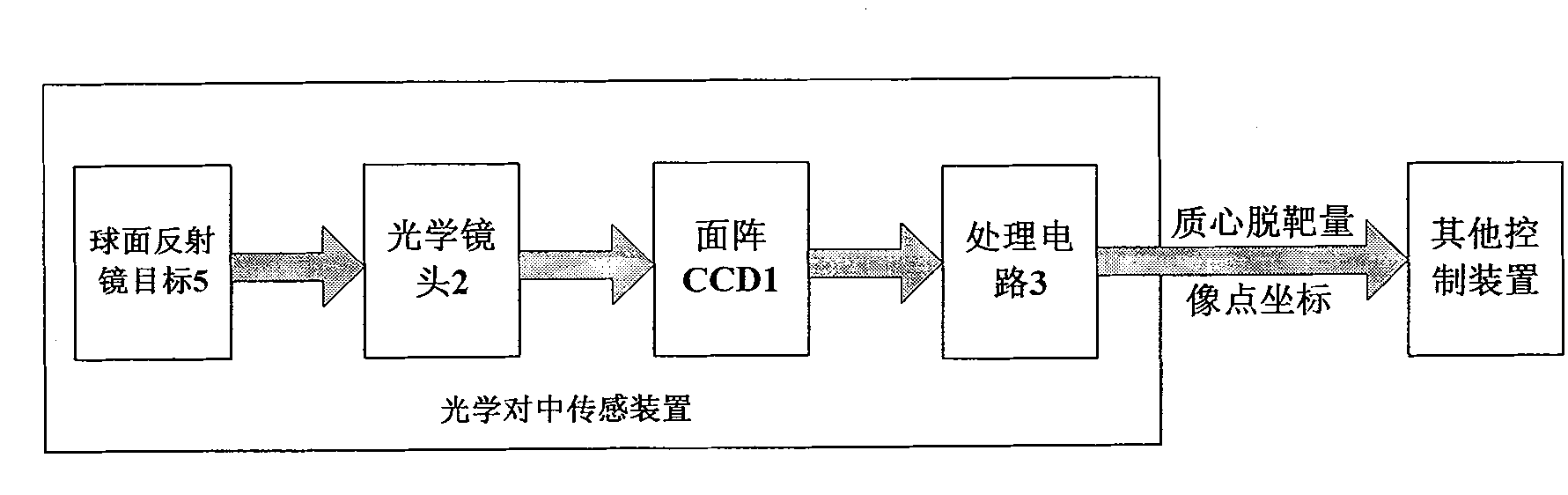

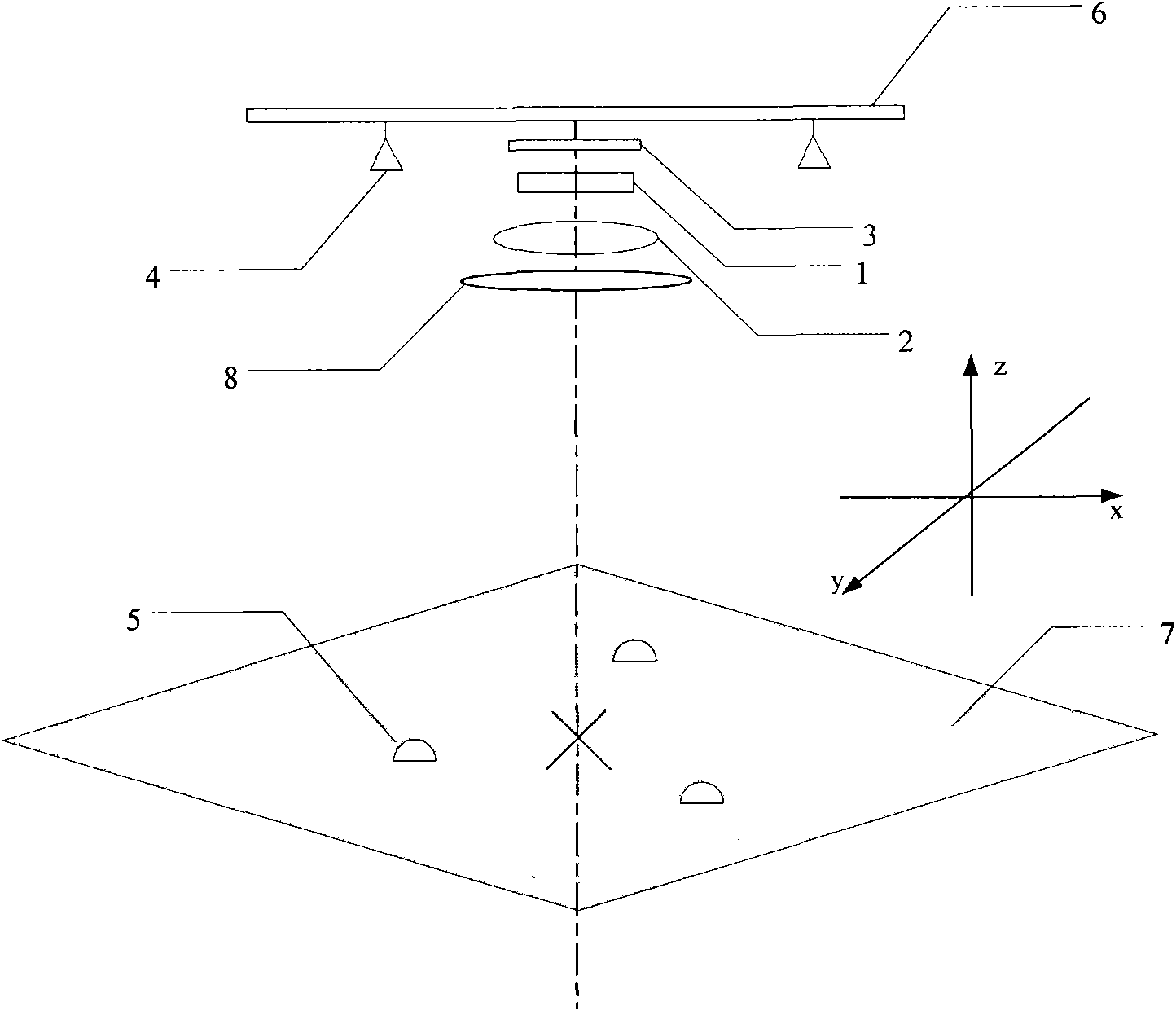

[0019] The system adopted by this measurement device includes: area array CCD1, optical lens 2, video processing circuit 3, LED red light source 4, spherical reflector 5, plane 6, non-reflective plane 7, (such as figure 2 shown).

[0020] The optical lens 2 can ensure that the image of the spherical mirror 5 can be imaged on the target surface of the area array CCD1.

[0021] The processing circuit 3 processes the image digital signal in real time, and completes the acquisition, processing and output of the image data of the area array CCD1.

[0022] Measurement method and working process:

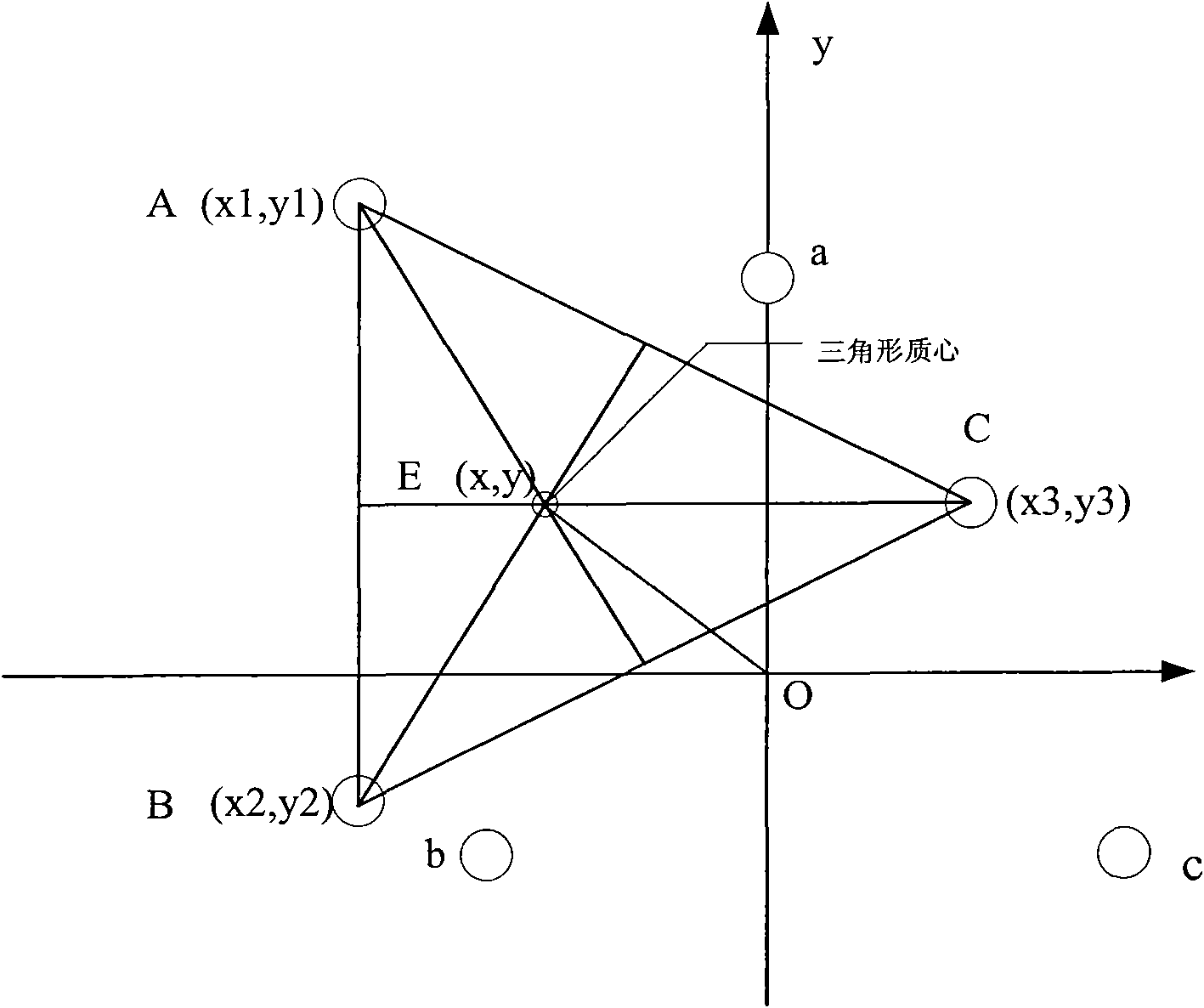

[0023] as attached figure 2 , use red light source 4 to illuminate three spherical reflectors 5, the centroids of the three spherical reflectors are the center of the plane, and through the imaging of the reflectors by the camera, the amount ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com