Method for separating and purifying L-ornithine by using simulated moving bed

A technology of simulating moving bed and ornithine, applied in separation methods, chemical instruments and methods, solid adsorbent liquid separation, etc., can solve the problem of L-ornithine fermentation broth with many impurities and low L-ornithine yield , large consumption of water and eluent, etc., to achieve the effect of eliminating acid and alkali consumption, reducing extraction cost and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The above-mentioned L-ornithine fermentation liquid first uses the ultrafiltration method (150,000 Dalton titanium dioxide ceramic membrane ultrafiltration, the ultrafiltration operating pressure is 0.38MPa, and the operating temperature is 55°C) to remove bacteria and solids to obtain ultrafiltration. Liquid (ie feed liquid, the same below);

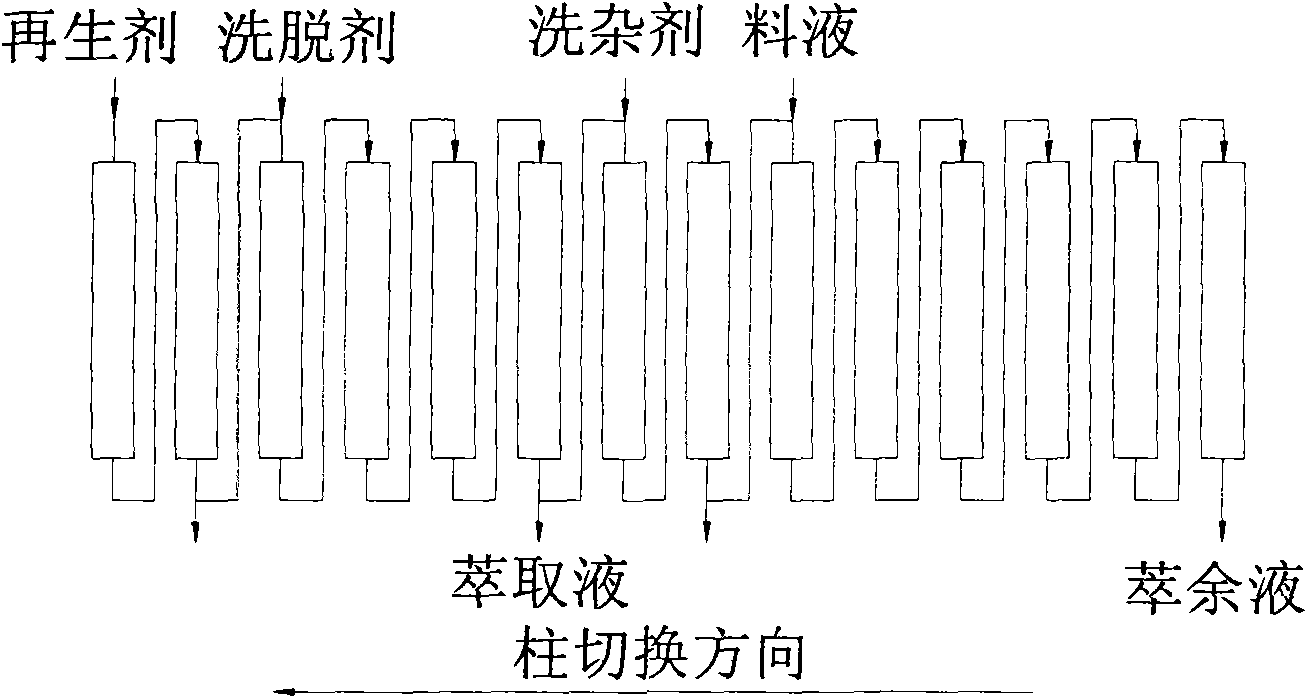

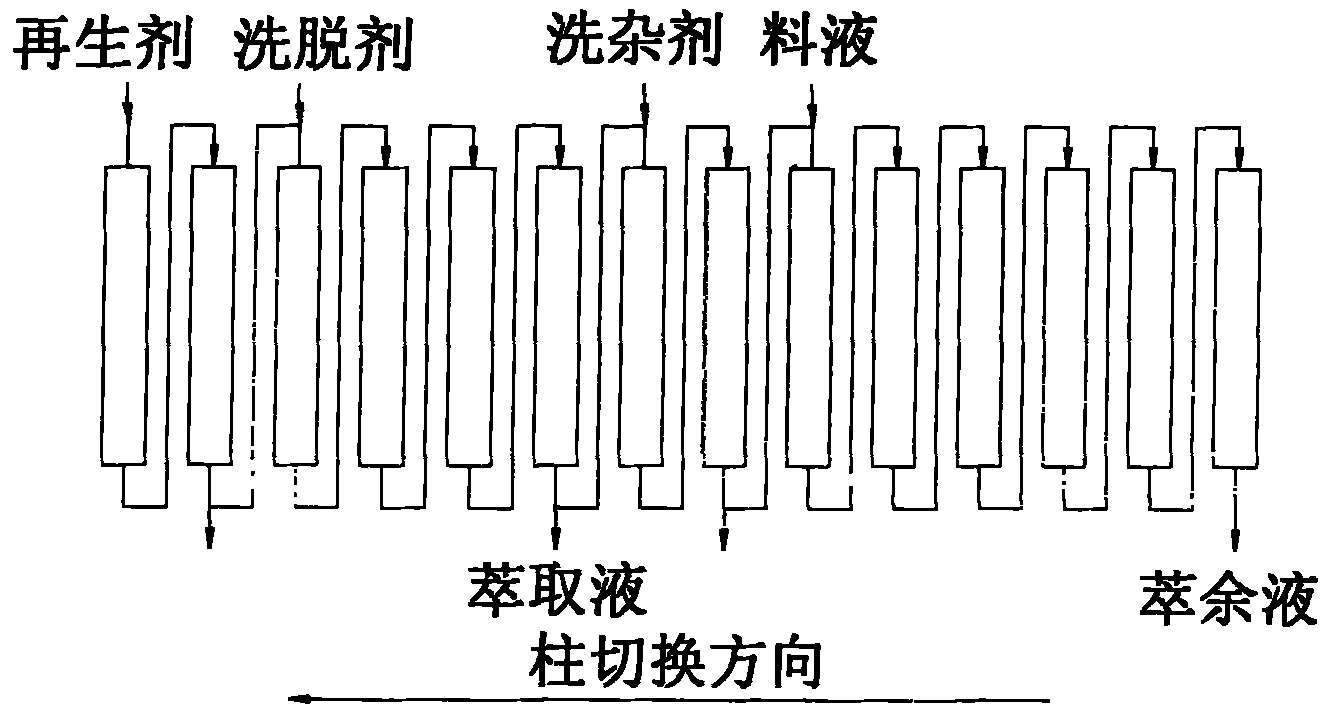

[0045] combine figure 1 , the simulated moving bed system is sequentially divided into four areas: adsorption area, washing area, elution area and regeneration washing area; the feed liquid inlet and raffinate outlet are located in the adsorption area, and the washing agent inlet and washing liquid outlet are located in the washing area. Miscellaneous area, the eluent inlet and extractant (i.e. eluent, the same below) outlet are located in the elution area, and the regenerant inlet and outlet are located in the regeneration area; the simulated moving bed system uses 14 columns, of which there are 6 columns in the adsorption area....

Embodiment 2

[0050] The above-mentioned L-ornithine fermentation broth is firstly removed by ultrafiltration (150,000 Dalton titanium dioxide ceramic membrane ultrafiltration, the ultrafiltration operating pressure is 0.38MPa, and the operating temperature is 58°C) to remove bacteria and solids to obtain ultrafiltration. Liquid (i.e. feed liquid);

[0051] combine figure 1 , the simulated moving bed system is sequentially divided into four areas: adsorption area, washing area, elution area and regeneration washing area; the feed liquid inlet and raffinate outlet are located in the adsorption area, and the washing agent inlet and washing liquid outlet are located in the washing area. Miscellaneous area, the eluent inlet and extract outlet are located in the elution area, the regenerant inlet and outlet are located in the regeneration area; the simulated moving bed system uses 14 columns, of which there are 6 columns in the adsorption area, 2 columns in the washing area, and 2 columns in the...

Embodiment 3

[0056] The above-mentioned L-ornithine fermentation broth is firstly removed by ultrafiltration (50,000 Dalton titanium dioxide ceramic membrane ultrafiltration, the ultrafiltration operating pressure is 0.35MPa, and the operating temperature is 60°C) to remove bacteria and solids to obtain ultrafiltration. Liquid (i.e. feed liquid);

[0057] combine figure 1 , the simulated moving bed system is sequentially divided into four areas: adsorption area, washing area, elution area and regeneration washing area; the feed liquid inlet and raffinate outlet are located in the adsorption area, and the washing agent inlet and washing liquid outlet are located in the washing area. Miscellaneous area, the eluent inlet and extract outlet are located in the elution area, the regenerant inlet and outlet are located in the regeneration area; the simulated moving bed system uses 14 columns, of which there are 6 columns in the adsorption area, 2 columns in the washing area, and 2 columns in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com